In Floor Cleaning Systems

Some pool owners love their In-Floor Cleaning System (IFCS), and others hate it. However, there is no argument that an IFCS adds complexity to the pool system. Many owners of pools with IFCS say they would not get it again.

An in-floor cleaning system is a pop-up cleaning system on your pool floor. It consists of a series of heads that pop up on the pool's floor and steps. They aim to drive dirt and debris towards an in-floor drain point in the pool's deep end. These cleaner heads are typically scattered along the pool floor to clean the pool from different zones.

Caretaker is the original in-floor pool cleaning system, developed in 1972. It replaced vacuum hoses and other stand-alone pool cleaners. In those days, pools used high-horsepower single-speed pumps with pressure to power water distribution valves. Modern pools can now have variable-speed pumps that run at slow flows and robotic pool cleaners. An IFCS can still be attractive to those who don't like the handling, wires, and cost of a robot cleaner and are willing to maintain the system's complexity.

An IFCS can be installed in a gunite/plaster, vinyl liner, or fiberglass pool. The system is designed for the pool plumbing before the swimming pool is constructed or manufactured.

IFCS is very common in Arizona and the Southwest, but in the North less so. They work great in areas with dust and not many deciduous trees. They don’t work well in regions that have a lot of trees and a lot of leaves. You may be told that they work just fine with leaves. But they don’t work as well as robotic cleaners for picking up big debris. If you live in an area that gets a lot of dust and not a lot of leaves, then it’s perfect. If you don’t live in that environment, don’t do it. Get a robotic cleaner.

An IFCS may have dead spots where debris gets trapped. You must help the system by brushing those spots or using another cleaner. If there is a lot of debris on the pool floor, the IFCS will take quite a while to remove it. The main drains won't appear to suck leaves in from even a few inches away. But if the leaves get closer, they will eventually go into the drains. If there are many leaves, use a net to remove them. The IFCS is not designed for significant cleanup jobs - it's for daily cleanup.

IFCS is difficult to winterize and is usually found in areas where pools run year-round. To be practical, closing and winterizing an IFCS system must be considered during design and construction.

It is not practical to retrofit an IFCS to an existing pool.

IFCS Manufacters

There are only a few current manufacturers of In-Floor Cleaning Systems. Paramount, A&A Manufacturing (now part of Pentair), Zodiac/Jandy Caretaker and Blue Square are often used.

In Australia, Cooke Industries sells QuikClean IFCS with the water valves, popups, and names of some products on their website looking identical to A&A Manufacturing (now Pentair) products. Waterco sells the Blue Square Q360 system.

Older systems that are no longer sold include Master Pools and Techni-Clean Systems. A search can find parts for these systems.

The Pentair/A&A system is the simplest of the group. Instead of the pool builder, Pentair/A&A, Paramount, and Zodiac/Jandy Caretaker design the pools' IFCS plumbing. A member called Paramount about their IFCS and they were able to send him the original design document.

Pentair/A&A, Zodiac/Jandy Caretaker, and maybe others give the original pool owner a lifetime warranty.

Not every builder may be authorized to install one of the above-listed IFCS manufacturer's products.

IFCS Components

An IFCS has pop-up cleaner heads, usually water-powered distribution valves (except for the Zodiac Caretaker, which uses an electric water valve), and, optionally, venturi skimmers. The distribution valves have complex gears that cycle through the zones.

Most IFCS problems come from low pump water pressure, worn gear trains, or sticky pop-up heads.

IFCS Operation

When the IFCS is activated, water should be pulled from the main drains and any skimmers. If no water is pulled from the main drains, the floor debris has nowhere to go, and the in-floor heads will blow it around.

If you have a VS pump, it needs to run at a speed that provides enough water pressure in the IFCS to cycle the zone valves and pop up the cleaning heads in the active zone.

The water zone valve is powered by water pressure and has gears that cycle the water flow from zone to zone. Each zone is active for a set time.

20%-25% main drain/75%-80% skimmer works best for most IFCS, giving a good balance for debris pickup through the main drain and adequate skimming. It's imperative that the main drain and skimmer(s) are plumbed separately back to the pad and have diverter valves to fine-tune the flow from each suction line

When working correctly, the water from the pop-up heads pushes dirt toward the floor drains, where it flows into the filter.

The IFCS popups are dedicated to cleaning and sweeping only the bottom and sides of your pool. They do not provide “surface cleaning," which is the function of wall jets and skimmer suction.

IFCS Design

There are many ways an IFCS can be installed. The designs can include:

- The IFCS system must run full-time to clean and do standard pool filtration and chlorination. The system does not have the usual skimmers and returns, and all return flow comes out of the in-floor heads

- IFCS system with in-floor heads and skimmers but no in-wall returns. So all return flow comes out of the in-floor heads

- Both an IFCS system and traditional skimmers and wall returns, including valves to select whether the system runs with the IFCS or without.

- One filtration pump that services all pool equipment, including the IFCS

- Two pumps with a dedicated IFCS pump that independently runs for cleaning. A two-pump design allows for separate filtration/chlorination and cleaning operations. A two-pump design maximizes flexibility but adds cost and complexity to the pool.

- Every IFCS zone pump should have its own suction line and filter. If the water returns directly to the water valve, not through a filter, debris can impede the system from correctly operating - as some of the debris and finer dirt will get through the pump basket. It is always best to use filtered water for IFCS.

- A shallow play pool should have valved separate returns so the returns can be run without the cleaning heads popping up, preventing toe stubbing.

- A well designed IFCS in a play pool (or any pool) is set to trigger the zones in a specific sequence to maximize cleaning efficiency. With a play pool whose depth is 3'- 4' - 5' - 4', the IFCS would cycle through 5 zones to push debris towards the drains in the 5' area:

- starts on steps/shelf

- then 3'

- adjacent 4'

- far end 4'

- finally, 5' pushing the debris into the main drains and then repeating in that sequence.

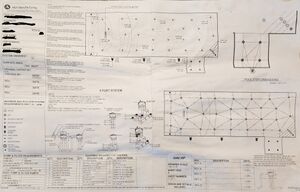

Below is an example of an A&A Cleaner design:[1]

You don't want an IFCS that cannot be turned off. You want regular skimmers and returns and the ability to switch between the IFCS and standard skimming/returns.

An in-floor system works by simply moving dirt and debris around until it reaches a main drain, where it’s picked up. There is a gravity assist in a traditional pool with a deep well with a drain at the bottom, and the system works well.

Even with an IFCS, we suggest a GFCI-protected electrical outlet about midway along the pool's length—and at least the minimum distance required by code from the water's edge—for a possible future robot. You may also want a suction-side manual vacuum/pool cleaner line installed. This will provide several options for cleaning over the pool's life.

A venturi skimmer uses return flow to help with skimming. Venturi skimmers are installed on many pools without IFCS, and many pools with IFCS don't have a venturi skimmer. A venturi skimmer is great with a VS pump, as the low pump RPM may not allow adequate skimming, but the return water flowing to the skimmer venturi improves skimming at lower RPMs.

In the venturi skimmers I've seen, a vac plate is necessary for a suction side vac if no dedicated vac line is available. Having a separate vac/cleaner line will alleviate the need to plug a vac/cleaner into the skimmer, allowing skimming while the vac/cleaner is being used.

An IFCS requires a high pump RPM to work well and will thus use more electricity. You can need 2900 rpm to get adequate cleaning with an IFCS. An IFCS can run 2 hours twice daily at 2900 rpm for IFCS and the other 20 hours at 1200 rpm for continuous skimming and SWG chlorine production. Some run 24/7 by choice, but that doesn't mean you need to.

A pool with an IFCS has complex plumbing, and you want to get a plumbing schematic to understand how to operate the system in various situations.

IFCS Maintenance and Repairs

Pentair/A&A, Zodiac/Jandy Caretaker, and maybe others give the original pool owner a lifetime warranty. If you have problems with your IFCS and are the original owner, you should contact your builder or the manufacturer.

Pop-ups seem to wear out about every 4-5 years or so. Grit or dirt in the head or body can keep them from rotating.

If your heads are not popping up or rotating, the first thing to check is your filter PSI gauge and water valve PSI gauge, if you have one. High filter pressure and low water valve pressure indicate the filter needs to be cleaned or the cartridge replaced. You can remove the cartridge and run the pump and system to confirm the filter is the problem.

Also, remove and check the filter in the feed pipe. Try running the system without the filter to confirm if the feed pipe filter is also reducing the cleaning pressure.

Pentair/A&A

If you are the original pool owner, then A&A does an exchange of parts under warranty. If you call and report a problem or broken part, they will initially charge for the parts and ship them to you. Upon receipt, you take the old parts out and ship them back to A&A. Once they receive them and verify they aren't working to spec or are broken, they refund your money. In the end, mailing them back only costs you the shipping charge.[2]

Pop-ups run $70-ish or more each. The warranty will save you $$$$.

Most A&A heads are either low or high flow. There is a head that has three different-sized orifices and when installed, each head can be set for low, medium, or high flow.

The A&A venturi popup heads are the best option. In theory, they adequately clean at a lower rpm than non-venturi popups.

The plastic install tool is almost worthless as it’s pretty easy to break. The metal install tool is much better, but it costs a lot.

A&A IFCS does not have a pressure gauge on or near the water valve.

The A&A system has an adjustment inside—but it is for how quickly each zone cycles, not for pressure on the system. A water diverter adjusts how much water goes to or is diverted from the impeller.

Paramount IFCS

PCC2000 Valve Module Repair Journey describes how a member fixed his system. He has two water valves - a four-port water valve and a six-port version that when it is receiving water from the first water valve. He learned that the valve module for the four-port water valve is not interchangeable with the valve module for the six-port water valve. You have to have the correct module in the correct water valve. The four-port water valve has to be oriented correctly so that the fourth, ganged port is over the water line that goes to the second water valve.

There are three long curved slots along the edge of Paramount cleaner heads where you are supposed to turn them. They make a special tool for removing them that you can buy; ir you can make your own tool with a 2x4 with 3 tiny nails not pounded in all the way. If you search online you can see what it looks like so you can make something similar.

Winterizing a Paramount In-Floor Cleaning system

Zodiac/Jandy Caretaker

The Zodiac Caretaker in-floor pool cleaning system has two valve options: the 5-Port valve and the electronically driven UltraFlex 8-Port valve, which provides multiple timer capabilities. Caretaker 5-port valves are sealed at the factory and ready for installation without adjustment.

Typically, the tang corners get bent and jammed. If you are the original owner, the hardware has a lifetime warranty (Gear set 800-822-7933, Pop-ups 855-280-6465).[3]

A 5-port valve must have at least 12 - 14 psi for the pop-ups to lift high enough to rotate.

If a pop-up is not working, remove it, pull the tab up, and let it snap back in place. Rotate them through the cycle. Sometimes, that buys you time. Remove the pop-up on the farthest end in each line and let the gear set go through the cycle. That can clear trash in the pop-up water line.

Blue Square

Grit in the head/body doesn't allow pop-up heads to rise completely. A set of "teeth" turns the head each time it retracts, but it has to get high enough to disengage and re-engage the next setting.[4]

- ↑ https://www.troublefreepool.com/threads/question-about-manual-vacuuming.260316/#post-2276399

- ↑ https://www.troublefreepool.com/threads/question-about-manual-vacuuming.260316/post-2276437

- ↑ https://www.troublefreepool.com/threads/caretaker-99-head-refurbish.291771/post-2559885

- ↑ https://www.troublefreepool.com/threads/blue-pop-up-cleaner.282134/post-2471739