The Hayward Goldline Aqua Logic automation and chlorination models AQL-PS-4, AQL-PS-8-V, AQL-PS-8 AQL-PS-16-V, AQL-PS-16 use the GLX-PCB-MAIN board.

Low Salt

Low salt messages are often the first indication of a failing cell. Don't add salt until you verify the water salt level with a Taylor K-1766 Test Kit or Salt test strips.

High Salt/Amps

The high salt warning comes on when the current exceeds 8 amps. This can be caused by high salt but also by high water temperatures. [1]

Check under the diagnostics menu for the correct cell size. If you select the cell size to t-3, t-5 or t-9 instead of the correct t-15 then the salt readout from the controller will be high salt.[2]

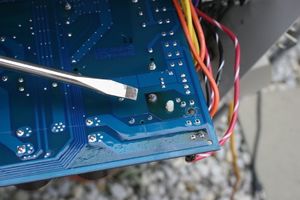

Common cause is failure of the solder joint to the K1 relay.[3] The K1 relay does not need to be replaced. It only needs to be re-soldered. To check if this might be your problem, unscrew the mother board and turn it over, if there is black smoke/burn marks at the K1 relay solder point, this is likely your problem.

Tips

- high amps can "blow" the solder joint and that high amps are most often caused by salt levels being too high.

- the motherboard has a 20 amp fuse on it. Unfortunately it seems the Amp limit on the relay is 20 amps too. It has been strongly recommended to replace the 20 amp fuse with a 15 Amp fuse to thus protect the relay and the K1 solder point.

- The K1 problem causes amps to always be exactly zero.[4]

- Use a 30 watt soldering iron and 60/40% rosin core (solder lead)

- Your don’t have to unhook mother board wires. Just turn it over. Make sure it is level before adding solder.[5]

- There are different versions of the main board. You can find various pictures in this thread.

.

- ↑ https://www.troublefreepool.com/threads/aqua-logic-salt-too-high-cholrinator-off-high-salt-amps.34466/post-1256487

- ↑ https://www.troublefreepool.com/threads/aqua-logic-salt-too-high-cholrinator-off-high-salt-amps.34466/post-287663

- ↑ https://www.troublefreepool.com/threads/aqua-logic-salt-too-high-cholrinator-off-high-salt-amps.34466/post-310225

- ↑ https://www.troublefreepool.com/threads/aqua-logic-salt-too-high-cholrinator-off-high-salt-amps.34466/post-657023

- ↑ https://www.troublefreepool.com/threads/aqua-logic-salt-too-high-cholrinator-off-high-salt-amps.34466/post-1638689