| (82 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

==Types of PVC== | ==Types of PVC== | ||

| + | |||

| + | ===Rigid Schedule 40=== | ||

| + | |||

[[File:PVC Schedule 40 Sweep.jpg|150 px|thumb|Sched 40 Sweep]] | [[File:PVC Schedule 40 Sweep.jpg|150 px|thumb|Sched 40 Sweep]] | ||

Shopping for pool PVC parts can be confusing. Especially at the "big box' stores where they have PVC suitable for house plumbing mixed in with PVC suitable for pools. It is important to check the markings and select the correct PVC pipes and fittings for use in a pool. | Shopping for pool PVC parts can be confusing. Especially at the "big box' stores where they have PVC suitable for house plumbing mixed in with PVC suitable for pools. It is important to check the markings and select the correct PVC pipes and fittings for use in a pool. | ||

| − | Pool PVC (polyvinyl chloride) should be marked "Schedule 40". Schedule 40 PVC is made for water under pressure. If the pipe has ASTM D 1785 on the pipe, it's suitable for pressure applications. A rating of ASTM D 2665 means non pressure applications and should not be used for pools.<ref>https://www.troublefreepool.com/threads/sch-40-dwv-280psi-pvc-question.192390/post-1695456</ref> | + | Pool PVC (polyvinyl chloride) should be marked "Schedule 40". Schedule 40 PVC is made for water under pressure. If the pipe has ASTM D 1785 on the pipe, it's suitable for pressure applications. A rating of ASTM D 2665 means non pressure applications and should not be used for pools.<ref>https://www.troublefreepool.com/threads/sch-40-dwv-280psi-pvc-question.192390/post-1695456</ref> |

A pipe can be dual rated ASTM D 1785 and ASTM D 2665, but it has to say ASTM D 1785 if it's going to be used for pressure. | A pipe can be dual rated ASTM D 1785 and ASTM D 2665, but it has to say ASTM D 1785 if it's going to be used for pressure. | ||

| Line 13: | Line 16: | ||

You may also find Schedule 80 PVC in stores. Schedule 80 PVC is designed for higher pressure applications and can be used in place of Schedule 40 PVC. | You may also find Schedule 80 PVC in stores. Schedule 80 PVC is designed for higher pressure applications and can be used in place of Schedule 40 PVC. | ||

| + | |||

| + | Note: ASTM D1785 is for pipe. | ||

| + | |||

| + | ASTM D1784 is the specification for the PVC material. | ||

| + | |||

| + | ASTM D2466 is the correct rating for the fittings. | ||

| + | |||

| + | https://assets.speakcdn.com/assets/2683/energy_efficient_sweep_els_specification_2020.pdf | ||

| + | |||

| + | ===Clear Schedule 40 PVC=== | ||

| + | |||

| + | PVC Fittings Online sells [https://www.pvcfittingsonline.com/2-clear-pvc-sch-40-pipe-pl-020.html Spears brand clear PVC pipe] as 5' sticks. | ||

| + | |||

| + | They also have [https://www.pvcfittingsonline.com/2-inch-clear-pvc-coupling-429-020l.html Clear PVC Couplings] and [https://www.pvcfittingsonline.com/2-clear-pvc-tee-401-020l.html Clear PVC Tees]. | ||

| + | |||

| + | ===DWV (Drain, Waste, Vent)=== | ||

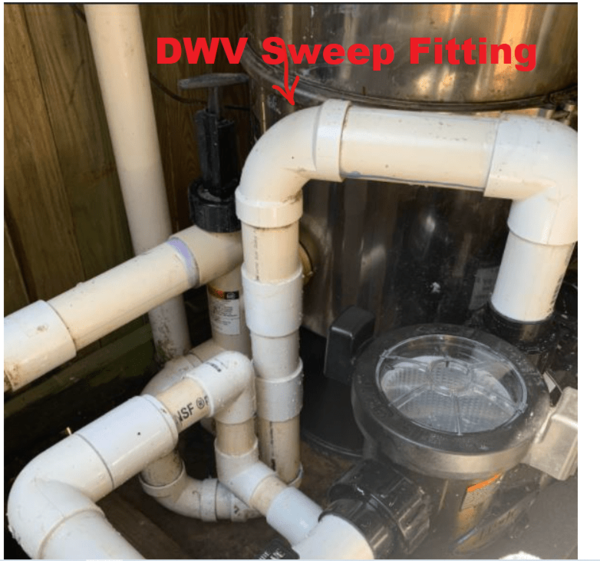

[[File:PVC DWV Sweep.jpg|150 px|thumb|PVC DWV Sweep]] | [[File:PVC DWV Sweep.jpg|150 px|thumb|PVC DWV Sweep]] | ||

You will find PVC pipe and fittings marked DWV (Drain, Waste, Vent) in the plumbing areas of big box stores. DWV is for non-pressurized plumbing and should not be used for a pool. DWV PVC has thinner walls then Schedule 40 PVC. | You will find PVC pipe and fittings marked DWV (Drain, Waste, Vent) in the plumbing areas of big box stores. DWV is for non-pressurized plumbing and should not be used for a pool. DWV PVC has thinner walls then Schedule 40 PVC. | ||

| − | You can visually tell the difference between pool rated Schedule 40 PVC and DWV PVC parts. Schedule 40 PVC parts have deeper hubs (ends) then DWV PVC parts. The shallower ends on DWV parts is the way to identify their incorrect use in pool plumbing. | + | You can visually tell the difference between pool rated Schedule 40 PVC and DWV PVC parts. Schedule 40 PVC parts have deeper hubs (ends) then DWV PVC parts. The shallower ends on DWV parts is the way to identify their incorrect use in pool plumbing. |

| + | |||

| + | [[File:Plumbing DWV Sweep Fitting.png|600px|frameless]] | ||

| + | |||

| + | The socket depth for schedule 40 is about 1.3" deep. | ||

| + | ===CPVC=== | ||

You may also see CPVC products. Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin, which is significantly more flexible and can withstand higher temperatures than standard PVC. CPVC is sometimes used in pump unions. CPVC can withstand heat and can safely carry drinking water. | You may also see CPVC products. Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin, which is significantly more flexible and can withstand higher temperatures than standard PVC. CPVC is sometimes used in pump unions. CPVC can withstand heat and can safely carry drinking water. | ||

| + | |||

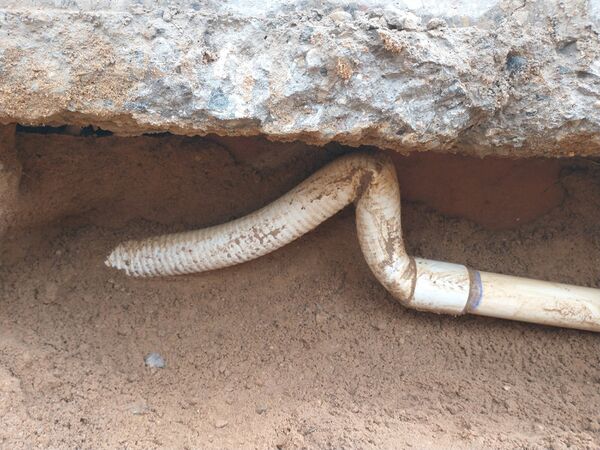

| + | ===Flex PVC=== | ||

| + | |||

| + | Flex PVC has its uses as long as it is good quality schedule 40 flex PVC. Around spas and in spa walls is one of them. For long buried runs rigid PVC has more puncture resistance and can be longer lasting. | ||

| + | |||

| + | Flex is great if you’re pool builder installing a pool you’ll never have to maintain. Flex is terrible for the pool owner that has to live with the pool. | ||

| + | |||

| + | [[File:Flex PVC Hose Kink.jpg|600px|frameless]] | ||

| + | |||

| + | Sources for flexible PVC are: | ||

| + | |||

| + | *[https://superflex.com/products-categories/pool-and-spa-hose-for-hot-tubs-and-swimming-pools/#419 Superflex] | ||

| + | *[https://flexpvc.com/Products/Sch40PVCPipe.shtml FlexPVC] | ||

| + | |||

| + | The following is from the [https://flexpvc.com/Guides/FAQ.shtml Flexible PVC Pipe FAQ]. | ||

| + | |||

| + | <blockquote>''When is "schedule 40" not schedule 40?'' | ||

| + | |||

| + | ''There are two "Schedule 40" ratings.'' | ||

| + | |||

| + | ''One is for dimensions and the other is for usage. Our flexible PVC is the same dimensions as Sch 40 pipe, but it's different from rigid pvc pipe in 2 very big ways:'' | ||

| + | |||

| + | ''1) Flexible PVC pipe is not rated for potable (drinking) water, and'' | ||

| + | |||

| + | ''2) Flexible PVC pipe will not take the same pressure rigid pvc will. (See [http://dims.flexpvc.com/ PVC Pipe pressure & dimension chart].)'' | ||

| + | |||

| + | ''Also, Flexible PVC pipe is treated as a hose by the building industry, not a pipe.'' | ||

| + | |||

| + | ''Thus our hose fits Schedule 40 fittings (dimensionally) and can be used in place of schedule 40 pipe for many applications, but it does not meet all the requirements for schedule 40 pipe. (If you look at the specification on the [http://dims.flexpvc.com/ PVC Pipe pressure & dimension page] you'll see the pressure ratings are not the same as schedule 40 pipe.)'' | ||

| + | |||

| + | ''So, while we call it "flexible pvc pipe" in reality it's a hose that fits perfectly into schedule 40 fittings, but it has a lower pressure rating, can't take dead head pressure and it not approved for potable water. (Potable water means approved for human consumption.) Irrigation, fish, nurseries, farming, livestock, etc are all okay provided you don't exceed the pressure ratings.'' | ||

| + | |||

| + | ''There is also some information on this on [https://flexpvc.com/Reference/FullPVCPipeChart.shtml Understanding and Identifying Your Pipe & Fittings]''.</blockquote> | ||

| + | |||

| + | Note that flex PVC has a minimum bend radius and can be kinked if bent too sharply. Minimum bend radius for 1 1/2" flex PVC is 5" and 2" flex PVC is 8".<ref>https://www.troublefreepool.com/threads/pool-pipe-collapse-near-skimmer.241543/post-2116867</ref> | ||

| + | |||

| + | [[File:Flex PVC Pool Pipe Collapse.jpg|600px|frameless]] | ||

==Cutting PVC== | ==Cutting PVC== | ||

| Line 28: | Line 89: | ||

A power miter saw or band saw is handy for cutting the new pieces to length if you have one. | A power miter saw or band saw is handy for cutting the new pieces to length if you have one. | ||

| + | |||

| + | ==Standard dimensions of PVC Pipe== | ||

| + | |||

| + | {| class="wikitable" | ||

| + | |+ | ||

| + | Commonly used pool PVC and CPVC Pipes - Schedule 40 sizes | ||

| + | |- | ||

| + | ! Nominal Pipe Size!! Outside Diameter !! Inside Diameter | ||

| + | |- | ||

| + | | 3/4 || 1.050 || 0.824 | ||

| + | |- | ||

| + | | 1 || 1.315 || 1.049 | ||

| + | |- | ||

| + | | 1 1/2 || 1.900 || 1.610 | ||

| + | |- | ||

| + | | 2 || 2.375 || 2.067 | ||

| + | |- | ||

| + | | 2 1/2 || 2.875 || 2.469 | ||

| + | |- | ||

| + | | 3 || 3.500 || 3.068 | ||

| + | |} | ||

| + | |||

| + | [https://www.engineeringtoolbox.com/amp/pvc-cpvc-pipes-dimensions-d_795.html Standard dimensions and weight of PVC - Polyvinyl Chloride - and CPVC - Chlorinated Polyvinyl Chloride ] is a complete chart of PVC pipe specifications. | ||

==Uncoupling Existing PVC Components== | ==Uncoupling Existing PVC Components== | ||

| + | |||

| + | ===Hub Saver=== | ||

| + | |||

| + | Sometimes plumbers assemble valves, elbows, and couplers tightly together without much PVC between them to cut into. That requires you to remove a large section of plumbing before you get to a piece of PVC pipe that you can put a coupler onto. | ||

| + | |||

| + | A "hub saver" or "socket saver" is a "drill bit" kind of device that allows you to drill out a 1.5" or 2" pipe that is glued inside a valve body or connector. | ||

| + | |||

| + | See this page at [https://www.plumbingsupply.com/pvcsaver.html plumbingsupply.com] for pictures of how their PVC Fitting Savers work. | ||

| + | |||

| + | Home Depot sells a less expensive [https://www.homedepot.com/p/JONES-STEPHENS-1-1-2-in-Socket-Saver-J44150/302575484 1-1/2 in. Socket Saver by JONES STEPHENS]. | ||

| + | |||

| + | Pasco has a [https://pascospecialty.com/catalog/PASCO_CATALOG_C.pdf PVC Ram Bit] like the Jones Stephens socket saver. | ||

| + | |||

| + | There are videos on YouTube showing how a socket saver works.<ref>https://www.troublefreepool.com/threads/tx-freeze-jandy-valve-in-awkward-spot-suggestions.224462/post-1968091</ref> See [https://www.youtube.com/watch?v=KQGssYM5C2M PVC/ABS Socket Saver Instructional Video By: Everything Home TV] and [https://www.youtube.com/watch?v=UPzUBxvB8jo 4 GENIUS Ways To Remove Glued PVC Fittings | GOT2LEARN] | ||

===Using a Heat Gun if working with couplers=== | ===Using a Heat Gun if working with couplers=== | ||

| Line 47: | Line 145: | ||

File:PVC Uncoupling 5.jpg|PVC SWG connected | File:PVC Uncoupling 5.jpg|PVC SWG connected | ||

</gallery> | </gallery> | ||

| + | |||

| + | ==Coupling a Pipe Cut Flush with Concrete== | ||

| + | |||

| + | Should a pipe be cut off flush with concrete or buried underground, a [https://www.acehardware.com/departments/plumbing/pipe-fittings/plastic-fittings/4512315 MagicMend] will easily solve the problem. The MagicMend insider connector will join two pieces of PVC schedule 40 pipe together. | ||

| + | |||

| + | It is an "inside slip connector." They are designed to slip inside of PVC pipe. They're available in 1.5" or 2". | ||

| + | |||

| + | The MagicMend is in the middle of the picture below. It slides into the the 2" pipe inside the elbow to the right. | ||

| + | |||

| + | [[File:MagicMend Slip Coupler.png|thumb]] | ||

| + | |||

| + | Note that CPVC has a slightly smaller inside diameter (1.939") compared to regular PVC (2.067"). A standard MagicMend won't fit without modification as they are made for standard PVC. Force the extender into a CPVC pipe and it will split. Using a Magic Mend with CPVC can be made to work, but it is best tried by someone who has a lot of experience with PVC.<ref>https://www.troublefreepool.com/threads/hairline-crack-leak-on-pipe-to-chlorinator.266183/post-2329287</ref> | ||

==Stripped Screwholes in Valves== | ==Stripped Screwholes in Valves== | ||

| Line 62: | Line 172: | ||

Follow the basic gluing instructions in the Pool School article. | Follow the basic gluing instructions in the Pool School article. | ||

===Tips=== | ===Tips=== | ||

| + | *Wear gloves, latex or nitrile since PVC primer contains xylenes which dissolve the pvc to make a fused joint. Xylene is not good to get on your skin or inhale. | ||

*Use unions to connect to pumps, filters and SWG. | *Use unions to connect to pumps, filters and SWG. | ||

*Gluing PVC to CPVC you can use regular PVC glue if you give it 12 hours to set.<ref>https://www.troublefreepool.com/threads/glue-for-pvc-pipe-into-cpvc-jandy-valve.156350/post-1383484</ref> Or you can use the Oatys red can All Purpose Cement. | *Gluing PVC to CPVC you can use regular PVC glue if you give it 12 hours to set.<ref>https://www.troublefreepool.com/threads/glue-for-pvc-pipe-into-cpvc-jandy-valve.156350/post-1383484</ref> Or you can use the Oatys red can All Purpose Cement. | ||

*All brands have fast set glue types. There's nothing special about any brand. Faster setting glue is harder to work with. As long as you use good quality glue and give it plenty of time to dry, it's fine.<ref>https://www.troublefreepool.com/threads/sch-40-dwv-280psi-pvc-question.192390/post-1696188</ref> | *All brands have fast set glue types. There's nothing special about any brand. Faster setting glue is harder to work with. As long as you use good quality glue and give it plenty of time to dry, it's fine.<ref>https://www.troublefreepool.com/threads/sch-40-dwv-280psi-pvc-question.192390/post-1696188</ref> | ||

*While the Oaty website<ref>https://www.oatey.com/PlasticPipeCement</ref> says “Can I use All Purpose Cement to join PVC to CPVC? No. It is not recommended because it takes longer for CPVC to finish the curing process necessary to complete a strong bond after the cement is applied. CPVC is also rated for hot water use which will affect cure times. PVC is not rated for hot water temperatures.” We feel that for pool uses it is acceptable.<ref>https://www.troublefreepool.com/threads/glue-for-pvc-pipe-into-cpvc-jandy-valve.156350/</ref> | *While the Oaty website<ref>https://www.oatey.com/PlasticPipeCement</ref> says “Can I use All Purpose Cement to join PVC to CPVC? No. It is not recommended because it takes longer for CPVC to finish the curing process necessary to complete a strong bond after the cement is applied. CPVC is also rated for hot water use which will affect cure times. PVC is not rated for hot water temperatures.” We feel that for pool uses it is acceptable.<ref>https://www.troublefreepool.com/threads/glue-for-pvc-pipe-into-cpvc-jandy-valve.156350/</ref> | ||

| + | *Prefit the pipe using soapy water to get full penetration. It's still hard to get it to fit up but you have to do this to get a trued up and square installation with good penetration at each fitting. Then when everything is square mark the edges of each fitting with a pencil. Also mark a perpendicular line from the pipe to the fitting. Use a pencil not a magic marker since the glue will dissolve anything other than a pencil. When you glue the fittings line them up with the marks. The pipe will be perfectly square and look like a pro did it! | ||

| + | *You can use the "face" to "face" measure then add in the total make up (socket depth) in this case 3". Depending on your measuring and cutting technique you will need to further adjust that measure (after a few tries you will have a ver dependable standard). You can use a few scrap pieces as gunners (as in I'm not really gunna use that piece) to hold it together to get the actual measures. This only works when you use a tool that gives a nice square cut. | ||

| + | *Dope threaded PVC and do not glue. Biggest mistake is over tightening threaded connections.<ref>https://www.troublefreepool.com/threads/general-pool-build-questions.241628/post-2118726</ref> | ||

===Primers=== | ===Primers=== | ||

Purple PVC primer chemically cleans the surface of the pipes. Primer also softens the pipe surface so they bond together tightly. Primer should be used before PVC cement. | Purple PVC primer chemically cleans the surface of the pipes. Primer also softens the pipe surface so they bond together tightly. Primer should be used before PVC cement. | ||

| − | Purple primer is only colored so inspectors or any one else can tell primer was used. If you are not very careful it can be messy looking | + | Purple primer is only colored so inspectors or any one else can tell primer was used. If you are not very careful it can be messy looking.<ref>https://www.troublefreepool.com/threads/cpvc-to-pvc-bonding.180862/#post-1600421</ref> |

| + | |||

| + | For above grade pad connects you can use clear primer and clear heavy duty glue for neatness. | ||

===Glues=== | ===Glues=== | ||

Links for products the TFP members have used are provided for Members convenience. | Links for products the TFP members have used are provided for Members convenience. | ||

| + | PVC glue is clear, white, or blue. | ||

| + | |||

| + | *Try to get a good "blue" glue. They have more PVC in them than does clear. Makes a better joint. | ||

| + | *If you're going to use a fast set glue be well prepared and organized. You do not get a large window to join the pieces. Otherwise use a slow set glue and give yourself more time to adjust the joint. | ||

| + | *[https://www.oatey.com/products/oatey-hot-medium-blue-lava-pvc-cement--2080119577 Oatey Hot Medium Blue Lava PVC Cement] is formulated for wet conditions, quick pressurization and fast installation, and is easy to apply with included in-lid dauber. This is a blue, medium body, very fast setting PVC cement. | ||

| + | *[https://www.oatey.com/products/oatey-rainrshine-medium-blue-pvc-cement--28508265 Oatey Rain-R-Shine® Medium Blue PVC Cement] is formulated for wet conditions and quick pressurization, and is easy to apply with included in-lid dauber. This is a blue, medium bodied, fast set cement. | ||

*[https://tchristy.com/ Red Hot PVC Cement] has been used without primer.<ref>https://www.troublefreepool.com/threads/what-should-i-pipe-pump-install-with.178794/#post-1580589</ref> | *[https://tchristy.com/ Red Hot PVC Cement] has been used without primer.<ref>https://www.troublefreepool.com/threads/what-should-i-pipe-pump-install-with.178794/#post-1580589</ref> | ||

*[https://weldon.com/solvent-cements/pvc-cements/719-pvc/Weldon 10159 White 719 Extra Heavy-Bodied PVC Professional Industrial-Grade Cement Slow-Setting Low-Voc] | *[https://weldon.com/solvent-cements/pvc-cements/719-pvc/Weldon 10159 White 719 Extra Heavy-Bodied PVC Professional Industrial-Grade Cement Slow-Setting Low-Voc] | ||

*[https://www.oatey.com/125873/Category/1.-Cements,-Primers-&-Cleaners Oatey Cements & Primers] | *[https://www.oatey.com/125873/Category/1.-Cements,-Primers-&-Cleaners Oatey Cements & Primers] | ||

*[https://www.oatey.com/2371665/Product/N/Oatey-8-oz-All-Purpose-Cement Oatey® All Purpose Cement] is a medium-bodied, milky-clear cement for use on all schedules and classes of ABS, PVC and CPVC pipe and fittings up to 6'' diameter with interference fit. | *[https://www.oatey.com/2371665/Product/N/Oatey-8-oz-All-Purpose-Cement Oatey® All Purpose Cement] is a medium-bodied, milky-clear cement for use on all schedules and classes of ABS, PVC and CPVC pipe and fittings up to 6'' diameter with interference fit. | ||

| + | *[https://weldon.com/solvent-cements/pvc-specialty-cements/795-flex-pvc/ 795 glue] is required for spa flex to rigid pvc. | ||

| + | |||

| + | [[File:PVC Joint Curing Times.png|200 px|thumb]] | ||

| + | |||

| + | Other glues that should not be used but sometimes are: | ||

| + | |||

| + | *ABS glue is black and the solvent in ABS glue does not dissolve into the PVC as a proper PVC glue does, so it might adhere, but does not provide the actual chemical weld that takes place in a properly glued joint. ABS glue should be able to be peeled off a PVC pipe.<REF>https://www.troublefreepool.com/threads/need-advice-on-fiberglass-pool-crack-repair-and-plumbing-replacement.283548/post-2484217</REF> | ||

| + | *Electrical PVC glue is grey and pipes glued with gray glue, designed for use with electrical conduit, needs to be given at least overnight to cure before putting it under pressure. A lot of people like using it because it gives a bit more working time with the joint. Joints glued with grey glue can blow apart even after a couple of days in the cold weather. | ||

| + | *Oatey and Weld-On have PVC glue that is fine for schedule 40 PVC and is grey. | ||

| + | |||

| + | [[File:PVC with ABS GLue.jpg|thumb]] | ||

| + | |||

| + | ==Assembling Threaded Plastic Fittings== | ||

| + | |||

| + | [https://www.lascofittings.com/threads The "Do's and Don'ts" of Assembling Threaded Plastic Fittings] from Lasco Fittings provides a great explanation of the Do’s and Don’ts to not have threaded fittings crack. | ||

| + | |||

| + | From the Lasco article: | ||

| + | *Don't over-tighten joints by giving them "one more turn to be sure.” | ||

| + | *Do finger tighten plus one or two turns - No More. | ||

| + | *Don't use "stronger" Schedule 80 threaded fittings on the assumption that they may solve the problem of splitting through over-tightening. | ||

| + | *Do use only Schedule 40 threaded fittings with Schedule 40 pipe and fittings. | ||

| + | *Don't wrap Teflon tape or Teflon paste or pipe dope to add bulk to or to lubricate the joint. | ||

| + | *Do use a sealant for threaded joints. | ||

| + | *A sealing compound must be compatible to plastics. Many brands of pipe sealant contain oils, solvents or carriers that can damage plastic. A proper sealant must be certified by the manufacturer to be harmless to the fitting material and to not contaminate fluid in the pipe. Finally, a sealing compound must not lubricate the joint to the point that over-tightening is encouraged. Several sealants on the market meet all these requirements. | ||

| + | |||

| + | Pentair has the label below on some MPVs saying to use Plasto-Joint Stik only and not Teflon paste or pipe dope on the threads. Pentair also says to tighten hand tight plus 1 1/2 turn’s maximum. | ||

| + | |||

| + | [[File:Plasto-Joint Stik.jpg|thumb]] | ||

| + | |||

| + | [[File:Pentair MPV Plastio Joint Stick Label.jpg|thumb]] | ||

| + | |||

| + | [[File:Plasto-Joint Stik.jpg|thumb]] | ||

| + | |||

| + | Hayward MPV valves have the sticker below: | ||

| + | [[File:Hayward MPV Sticker.jpg|thumb]] | ||

| + | |||

| + | ==Supporting a Long PVC Pipe Run== | ||

| + | |||

| + | Long PVC runs in the air should be supported so that a joint does not crack if the pipe is leaned on. The picture below shows pipes that need support. | ||

| + | |||

| + | [[File:PVC Pipe Needing Support.jpg|thumb]] | ||

| + | |||

| + | To support a 1 1/2" pipe take a 2" T and cut off the top so it is open in a U and will slip onto the outside of the pipe. Then put a leg on it of the height needed for support. No water flows through it.<ref>https://www.troublefreepool.com/threads/exposed-pvc-pipe-stand-leg-holder.219613/</ref> | ||

| + | |||

| + | [[File:PVC Pipe Support.jpg|thumb]] | ||

==PVC Parts Sources== | ==PVC Parts Sources== | ||

| − | Schedule 40 parts are hard to find in the home improvement stores. | + | Schedule 40 parts are hard to find in the home improvement stores. If you want to shop locally find the places a plumber goes, not a store that has a plumbing aisle. [https://www.ferguson.com/ Ferguson] is a nationwide plumbing chain with many [https://www.ferguson.com/searchBranch locations]. |

| + | |||

| + | Below are online sources members have found useful: | ||

| + | |||

| + | [https://www.supplyhouse.com/PVC-Schedule-40-Fittings-14952000 Supply House] has a good selection of Schedule 40 PVC. | ||

[https://www.pvcfittingsonline.com/fittings/schedule-40-pvc.html?p=2 PVC Fittings Online] has a TON of PVC parts you can't find at HD or Lowes and shipping is affordable. They have a lot of the hard to find stuff like a 2" 90 with a 1" tee.<ref>https://www.troublefreepool.com/threads/pvc-parts.183931/</ref> | [https://www.pvcfittingsonline.com/fittings/schedule-40-pvc.html?p=2 PVC Fittings Online] has a TON of PVC parts you can't find at HD or Lowes and shipping is affordable. They have a lot of the hard to find stuff like a 2" 90 with a 1" tee.<ref>https://www.troublefreepool.com/threads/pvc-parts.183931/</ref> | ||

| + | |||

| + | [https://www.lascofittings.com/poolspa Lasco Fittings] has all sizes, schedules and configurations of Pool/Spa fittings. They can be found in many of the big box stores and online retailers. [https://assets.speakcdn.com/assets/1824/sch40_2017.pdf Lasco Schedule 40 Fitting Catalog] | ||

| + | |||

| + | [https://www.spearsmfg.com/ Spears Manufacturing] has an [https://www.parts.spearsmfg.com/Product.aspx?pid=1 Online Sourcebook] of Schedule 40 parts. | ||

| + | |||

| + | Anderson Manufacturing has [https://www.leaktools.com/kwik-repair-fittings.html Kwik Repair Fittings] that makes installation or repair of PVC lines faster, easier, and more cost efficient by requiring just one fitting. By using tapered sleeves which slide onto the pipe, repairs can be made without bending or flexing of the existing pipe. | ||

| + | |||

| + | Anderson Manufacturing also has [https://www.leaktools.com/1-12-extender-fitting.html Extender Fittings] that are used when replacing a standard glued in fitting, valve, etc. Extends the length of the new fitting so it can be re-glued onto the existing pipe. One end of this fitting goes over existing PVC pipe the other fits inside another plumbing fitting. Use this to repair plumbing or replace fittings where at least 1-1/4" of exposed pipe remains. | ||

| + | |||

| + | [https://www.toolsforpools.com/catalog_current_year.html Tools for Pools Catalog] has many problem solving products. | ||

==Use of 90 Degree Sweeps== | ==Use of 90 Degree Sweeps== | ||

| Line 96: | Line 277: | ||

*3.0".........138.............184 gpm | *3.0".........138.............184 gpm | ||

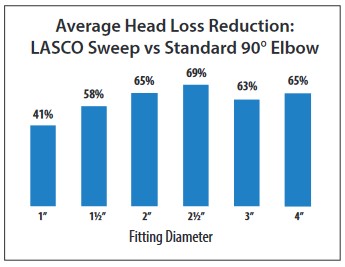

| + | Lasco provides the following chart on reduction in head loss for their 90 degree sweeps.<ref>https://assets.speakcdn.com/assets/1824/sweeps2013.pdf</ref> While the percentages look significant unless you have many 90 degree turns in the plumbing you will see no operational differences in the performance of your equipment using the sweeps. | ||

| + | |||

| + | [[File:Plumbing Lasco Average Head Loss Reduction 90 Degree Sweeps.jpg|400px|frameless]] | ||

| + | |||

| + | ==PVC Joint Leak Repair== | ||

| + | |||

| + | ===Marine Epoxy=== | ||

| + | |||

| + | For a leak at a joint on the pressure side near the pump, run the pump and have some "marine epoxy" mixed and ready, then wait for the leak.<ref>https://www.troublefreepool.com/threads/pvc-fitting-leak.221705/post-1942135</ref> | ||

| + | |||

| + | Shut off the pump and quickly dry where the leak is. Apply the epoxy immediately. | ||

| + | |||

| + | Once the pump is off, the water in the filter is no longer pressurized wants to fall out, but atmospheric pressure needs to get in for that to happen. This results in a suction situation were the leak is. The atmosphere will "push" the epoxy into the gap where it was leaking. It may take 2 applications. | ||

| + | |||

| + | Let it set for a day before starting pump. | ||

| + | |||

| + | This works like magic, and has fixed leaks that otherwise would have been a major undertaking. Mainly due to access issues. | ||

| + | |||

| + | Look for LOCTITE marine epoxy, widely available. Slathering PVC glue on the joint can also work. | ||

| + | |||

| + | ===Leak-B-Gone Ring=== | ||

| + | [[File:PVC Repair Leak B Gone Ring.jpg|150px|thumb]] | ||

| + | A member successfully repaired a slow drip joint at a coupler in 2" PVC using “Leak-B-Gone rings”.<ref>https://www.troublefreepool.com/threads/leak-repair-success.200931/post-1773034</ref> Essentially little snap on PVC collars that repair bad joints.<ref>https://www.homedepot.com/p/Leak-B-Gone-2-in-PVC-Repair-Ring-10-Pack-45035/205346966</ref> They may be worth a try before you do more elaborate surgery to a leaking PVC joint. | ||

| + | |||

| + | Leak-B-Gone PVC Pipe Repair rings are intended to permanently repair leaks at PVC pipe joints where the glue has not adhered properly during install, or where the joint has come loose. They are available in seven sizes for between 3/4 in. and 4 in. pipe. Leak-B-Gone rings are easily installed within 60 seconds, as they do not require the use of any outside tool. To install, simply apply primer and cement to the pipe and slide the Leak-B-Gone ring around the leaking pipe joint. | ||

| + | |||

| + | Leak-B-Gone rings can be found at Amazon and Home Depot and other supply stores. You will find videos on YouTube showing its use. | ||

| + | |||

| + | ==PVC Crack Repairs== | ||

| + | |||

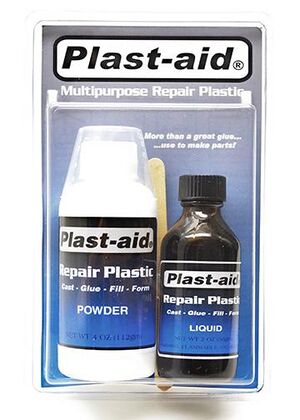

| + | Repair products members have used include<ref>https://www.troublefreepool.com/threads/cracked-skimmer.266025/post-2327751</ref>: | ||

| + | |||

| + | *[https://www.pcepoxy.com/products/permanent-repair/pc-11-paste-epoxy/ PC11 Epoxy] | ||

| + | *[https://www.plast-aid.com/ Plast-aid] | ||

| + | *[https://www.amazon.com/Atlas-Epoxy-Pool-Putty-Set/dp/B0002Z0NBY Atlas Epoxy Pool Putty] | ||

| + | |||

| + | Plast-aid has been used to repair cracks in skimmers and SWGs. It bonds well with PVC, and it's very strong. | ||

| + | |||

| + | [[File:Plast-Aid PVC Crack Repair.jpg|thumb]] | ||

| + | |||

| + | The fitting saver or Frankenplug can repair eaking return fittings, skimmer lines, and main drain lines within 14" of a wall: | ||

| + | |||

| + | *[https://www.leaktools.com/fitting-repair.html Fitting Saver] | ||

| + | *[https://frankwall.com/product/the-frankenplug/ Frankenplug] | ||

| + | |||

| + | ==Painting PVC== | ||

| + | |||

| + | Some jurisdictions, like Sacramento County California, require pool PVC to be painted.<ref>http://thomasinspections.com/files/Pool_SpaRequirementsSacCounty.pdf</ref> | ||

| + | |||

| + | Some PVC manufacturers recommend PVC pipes exposed to the direct effects of UV radiation be painted with a light-colored acrylic or latex paint that is chemically compatible with the PVC/CPVC products. Compatibility information should be confirmed with the paint manufacturer. The use of oil-based paints is not recommended.<ref>https://www.usplastic.com/knowledgebase/article.aspx?contentkey=774</ref> | ||

| + | |||

| + | With painting anything, prep is the key. Scuff with a Scotch Bright pad or sand paper and clean with acetone or alcohol and anything will stick to it. | ||

| + | |||

| + | Paints that people have used include: | ||

| + | *Rustoleum 2X paint and primer in one spray paint that says it is good for plastics | ||

| + | *Krylon Fusion | ||

| + | *BEHR ULTRA Stain-Blocking Paint + Primer in one. Less expensive than spray cans and NO OVERSPRAY on equipment. Once drop cloths are layed down and a bit of masking around the outer edges of the valve housings and compression fittings are complete, it's a breeze and comes out nice.<ref>https://www.troublefreepool.com/threads/best-quality-pvc-paint.277338/post-2434035</ref> | ||

| + | *"dip your car" type plasti dip/spray and it has a 3 to 10 year UV stable rating. | ||

. | . | ||

Latest revision as of 01:33, 25 May 2024

This Wiki page is a supplement to Swimming Pool Plumbing Repair in TFP Pool School. The Wiki provides additional detail on tools, products and methods for PVC Repair. All links to products and vendors are provided for the convenience of TFP Members and TFP receives no compensation from them.

Types of PVC

Rigid Schedule 40

Shopping for pool PVC parts can be confusing. Especially at the "big box' stores where they have PVC suitable for house plumbing mixed in with PVC suitable for pools. It is important to check the markings and select the correct PVC pipes and fittings for use in a pool.

Pool PVC (polyvinyl chloride) should be marked "Schedule 40". Schedule 40 PVC is made for water under pressure. If the pipe has ASTM D 1785 on the pipe, it's suitable for pressure applications. A rating of ASTM D 2665 means non pressure applications and should not be used for pools.[1]

A pipe can be dual rated ASTM D 1785 and ASTM D 2665, but it has to say ASTM D 1785 if it's going to be used for pressure.

The pipe should also be labeled NSF-PW (National Sanitation Foundation - Potable Water) and Schedule 40 PVC.

You may also find Schedule 80 PVC in stores. Schedule 80 PVC is designed for higher pressure applications and can be used in place of Schedule 40 PVC.

Note: ASTM D1785 is for pipe.

ASTM D1784 is the specification for the PVC material.

ASTM D2466 is the correct rating for the fittings.

https://assets.speakcdn.com/assets/2683/energy_efficient_sweep_els_specification_2020.pdf

Clear Schedule 40 PVC

PVC Fittings Online sells Spears brand clear PVC pipe as 5' sticks.

They also have Clear PVC Couplings and Clear PVC Tees.

DWV (Drain, Waste, Vent)

You will find PVC pipe and fittings marked DWV (Drain, Waste, Vent) in the plumbing areas of big box stores. DWV is for non-pressurized plumbing and should not be used for a pool. DWV PVC has thinner walls then Schedule 40 PVC.

You can visually tell the difference between pool rated Schedule 40 PVC and DWV PVC parts. Schedule 40 PVC parts have deeper hubs (ends) then DWV PVC parts. The shallower ends on DWV parts is the way to identify their incorrect use in pool plumbing.

The socket depth for schedule 40 is about 1.3" deep.

CPVC

You may also see CPVC products. Chlorinated polyvinyl chloride (CPVC) is a thermoplastic produced by chlorination of polyvinyl chloride (PVC) resin, which is significantly more flexible and can withstand higher temperatures than standard PVC. CPVC is sometimes used in pump unions. CPVC can withstand heat and can safely carry drinking water.

Flex PVC

Flex PVC has its uses as long as it is good quality schedule 40 flex PVC. Around spas and in spa walls is one of them. For long buried runs rigid PVC has more puncture resistance and can be longer lasting.

Flex is great if you’re pool builder installing a pool you’ll never have to maintain. Flex is terrible for the pool owner that has to live with the pool.

Sources for flexible PVC are:

The following is from the Flexible PVC Pipe FAQ.

When is "schedule 40" not schedule 40?

There are two "Schedule 40" ratings.

One is for dimensions and the other is for usage. Our flexible PVC is the same dimensions as Sch 40 pipe, but it's different from rigid pvc pipe in 2 very big ways:

1) Flexible PVC pipe is not rated for potable (drinking) water, and

2) Flexible PVC pipe will not take the same pressure rigid pvc will. (See PVC Pipe pressure & dimension chart.)

Also, Flexible PVC pipe is treated as a hose by the building industry, not a pipe.

Thus our hose fits Schedule 40 fittings (dimensionally) and can be used in place of schedule 40 pipe for many applications, but it does not meet all the requirements for schedule 40 pipe. (If you look at the specification on the PVC Pipe pressure & dimension page you'll see the pressure ratings are not the same as schedule 40 pipe.)

So, while we call it "flexible pvc pipe" in reality it's a hose that fits perfectly into schedule 40 fittings, but it has a lower pressure rating, can't take dead head pressure and it not approved for potable water. (Potable water means approved for human consumption.) Irrigation, fish, nurseries, farming, livestock, etc are all okay provided you don't exceed the pressure ratings.

There is also some information on this on Understanding and Identifying Your Pipe & Fittings.

Note that flex PVC has a minimum bend radius and can be kinked if bent too sharply. Minimum bend radius for 1 1/2" flex PVC is 5" and 2" flex PVC is 8".[2]

Cutting PVC

Cutting PVC is basically described in the Pool School article.

If you are working with 2" or larger PVC a Sawzall cuts it easily. They really do not sell a PVC cutter that works for larger PVC unless you pay a LOT of money for it. The $20 ones don't work at all.

A power miter saw or band saw is handy for cutting the new pieces to length if you have one.

Standard dimensions of PVC Pipe

| Nominal Pipe Size | Outside Diameter | Inside Diameter |

|---|---|---|

| 3/4 | 1.050 | 0.824 |

| 1 | 1.315 | 1.049 |

| 1 1/2 | 1.900 | 1.610 |

| 2 | 2.375 | 2.067 |

| 2 1/2 | 2.875 | 2.469 |

| 3 | 3.500 | 3.068 |

Standard dimensions and weight of PVC - Polyvinyl Chloride - and CPVC - Chlorinated Polyvinyl Chloride is a complete chart of PVC pipe specifications.

Uncoupling Existing PVC Components

Hub Saver

Sometimes plumbers assemble valves, elbows, and couplers tightly together without much PVC between them to cut into. That requires you to remove a large section of plumbing before you get to a piece of PVC pipe that you can put a coupler onto.

A "hub saver" or "socket saver" is a "drill bit" kind of device that allows you to drill out a 1.5" or 2" pipe that is glued inside a valve body or connector.

See this page at plumbingsupply.com for pictures of how their PVC Fitting Savers work.

Home Depot sells a less expensive 1-1/2 in. Socket Saver by JONES STEPHENS.

Pasco has a PVC Ram Bit like the Jones Stephens socket saver.

There are videos on YouTube showing how a socket saver works.[3] See PVC/ABS Socket Saver Instructional Video By: Everything Home TV and 4 GENIUS Ways To Remove Glued PVC Fittings | GOT2LEARN

Using a Heat Gun if working with couplers

Rather than cutting out the exiting PVC plumbing a member devised a successful method of uncoupling the piece and just gluing on the new coupler:[4]

- Using a heat gun soften the PVC coupler in one spot and peel up and expose the male PVC pipe the coupler is glued to.

- Then work the heat gun around while prying up the softened coupler all the way around until all coupler material is removed.

- Using 80, 150, and 300 grit sandpaper sand the surface clean and ensure a proper fit for the new coupler.

- Primer and glue the new coupler to the existing male PVC pipe.

- Check for leaks.

Coupling a Pipe Cut Flush with Concrete

Should a pipe be cut off flush with concrete or buried underground, a MagicMend will easily solve the problem. The MagicMend insider connector will join two pieces of PVC schedule 40 pipe together.

It is an "inside slip connector." They are designed to slip inside of PVC pipe. They're available in 1.5" or 2".

The MagicMend is in the middle of the picture below. It slides into the the 2" pipe inside the elbow to the right.

Note that CPVC has a slightly smaller inside diameter (1.939") compared to regular PVC (2.067"). A standard MagicMend won't fit without modification as they are made for standard PVC. Force the extender into a CPVC pipe and it will split. Using a Magic Mend with CPVC can be made to work, but it is best tried by someone who has a lot of experience with PVC.[5]

Stripped Screwholes in Valves

Sometimes this works, and sometimes it does not.[6]

Take off the lid and set it aside. Then using two-part slow-setting epoxy, fill all the screws holes, and then before the epoxy sets up, dip the screw threads into Vaseline and screw them into the holes. Let dry overnight.

In theory, the screws should back right out. Clean up the lid area and make sure to replace the o-ring or seal.

Install the lid and make sure not to torque the screws to 100 foot lbs.

Gluing PVC

Follow the basic gluing instructions in the Pool School article.

Tips

- Wear gloves, latex or nitrile since PVC primer contains xylenes which dissolve the pvc to make a fused joint. Xylene is not good to get on your skin or inhale.

- Use unions to connect to pumps, filters and SWG.

- Gluing PVC to CPVC you can use regular PVC glue if you give it 12 hours to set.[7] Or you can use the Oatys red can All Purpose Cement.

- All brands have fast set glue types. There's nothing special about any brand. Faster setting glue is harder to work with. As long as you use good quality glue and give it plenty of time to dry, it's fine.[8]

- While the Oaty website[9] says “Can I use All Purpose Cement to join PVC to CPVC? No. It is not recommended because it takes longer for CPVC to finish the curing process necessary to complete a strong bond after the cement is applied. CPVC is also rated for hot water use which will affect cure times. PVC is not rated for hot water temperatures.” We feel that for pool uses it is acceptable.[10]

- Prefit the pipe using soapy water to get full penetration. It's still hard to get it to fit up but you have to do this to get a trued up and square installation with good penetration at each fitting. Then when everything is square mark the edges of each fitting with a pencil. Also mark a perpendicular line from the pipe to the fitting. Use a pencil not a magic marker since the glue will dissolve anything other than a pencil. When you glue the fittings line them up with the marks. The pipe will be perfectly square and look like a pro did it!

- You can use the "face" to "face" measure then add in the total make up (socket depth) in this case 3". Depending on your measuring and cutting technique you will need to further adjust that measure (after a few tries you will have a ver dependable standard). You can use a few scrap pieces as gunners (as in I'm not really gunna use that piece) to hold it together to get the actual measures. This only works when you use a tool that gives a nice square cut.

- Dope threaded PVC and do not glue. Biggest mistake is over tightening threaded connections.[11]

Primers

Purple PVC primer chemically cleans the surface of the pipes. Primer also softens the pipe surface so they bond together tightly. Primer should be used before PVC cement.

Purple primer is only colored so inspectors or any one else can tell primer was used. If you are not very careful it can be messy looking.[12]

For above grade pad connects you can use clear primer and clear heavy duty glue for neatness.

Glues

Links for products the TFP members have used are provided for Members convenience.

PVC glue is clear, white, or blue.

- Try to get a good "blue" glue. They have more PVC in them than does clear. Makes a better joint.

- If you're going to use a fast set glue be well prepared and organized. You do not get a large window to join the pieces. Otherwise use a slow set glue and give yourself more time to adjust the joint.

- Oatey Hot Medium Blue Lava PVC Cement is formulated for wet conditions, quick pressurization and fast installation, and is easy to apply with included in-lid dauber. This is a blue, medium body, very fast setting PVC cement.

- Oatey Rain-R-Shine® Medium Blue PVC Cement is formulated for wet conditions and quick pressurization, and is easy to apply with included in-lid dauber. This is a blue, medium bodied, fast set cement.

- Red Hot PVC Cement has been used without primer.[13]

- 10159 White 719 Extra Heavy-Bodied PVC Professional Industrial-Grade Cement Slow-Setting Low-Voc

- Oatey Cements & Primers

- Oatey® All Purpose Cement is a medium-bodied, milky-clear cement for use on all schedules and classes of ABS, PVC and CPVC pipe and fittings up to 6 diameter with interference fit.

- 795 glue is required for spa flex to rigid pvc.

Other glues that should not be used but sometimes are:

- ABS glue is black and the solvent in ABS glue does not dissolve into the PVC as a proper PVC glue does, so it might adhere, but does not provide the actual chemical weld that takes place in a properly glued joint. ABS glue should be able to be peeled off a PVC pipe.[14]

- Electrical PVC glue is grey and pipes glued with gray glue, designed for use with electrical conduit, needs to be given at least overnight to cure before putting it under pressure. A lot of people like using it because it gives a bit more working time with the joint. Joints glued with grey glue can blow apart even after a couple of days in the cold weather.

- Oatey and Weld-On have PVC glue that is fine for schedule 40 PVC and is grey.

Assembling Threaded Plastic Fittings

The "Do's and Don'ts" of Assembling Threaded Plastic Fittings from Lasco Fittings provides a great explanation of the Do’s and Don’ts to not have threaded fittings crack.

From the Lasco article:

- Don't over-tighten joints by giving them "one more turn to be sure.”

- Do finger tighten plus one or two turns - No More.

- Don't use "stronger" Schedule 80 threaded fittings on the assumption that they may solve the problem of splitting through over-tightening.

- Do use only Schedule 40 threaded fittings with Schedule 40 pipe and fittings.

- Don't wrap Teflon tape or Teflon paste or pipe dope to add bulk to or to lubricate the joint.

- Do use a sealant for threaded joints.

- A sealing compound must be compatible to plastics. Many brands of pipe sealant contain oils, solvents or carriers that can damage plastic. A proper sealant must be certified by the manufacturer to be harmless to the fitting material and to not contaminate fluid in the pipe. Finally, a sealing compound must not lubricate the joint to the point that over-tightening is encouraged. Several sealants on the market meet all these requirements.

Pentair has the label below on some MPVs saying to use Plasto-Joint Stik only and not Teflon paste or pipe dope on the threads. Pentair also says to tighten hand tight plus 1 1/2 turn’s maximum.

Hayward MPV valves have the sticker below:

Supporting a Long PVC Pipe Run

Long PVC runs in the air should be supported so that a joint does not crack if the pipe is leaned on. The picture below shows pipes that need support.

To support a 1 1/2" pipe take a 2" T and cut off the top so it is open in a U and will slip onto the outside of the pipe. Then put a leg on it of the height needed for support. No water flows through it.[15]

PVC Parts Sources

Schedule 40 parts are hard to find in the home improvement stores. If you want to shop locally find the places a plumber goes, not a store that has a plumbing aisle. Ferguson is a nationwide plumbing chain with many locations.

Below are online sources members have found useful:

Supply House has a good selection of Schedule 40 PVC.

PVC Fittings Online has a TON of PVC parts you can't find at HD or Lowes and shipping is affordable. They have a lot of the hard to find stuff like a 2" 90 with a 1" tee.[16]

Lasco Fittings has all sizes, schedules and configurations of Pool/Spa fittings. They can be found in many of the big box stores and online retailers. Lasco Schedule 40 Fitting Catalog

Spears Manufacturing has an Online Sourcebook of Schedule 40 parts.

Anderson Manufacturing has Kwik Repair Fittings that makes installation or repair of PVC lines faster, easier, and more cost efficient by requiring just one fitting. By using tapered sleeves which slide onto the pipe, repairs can be made without bending or flexing of the existing pipe.

Anderson Manufacturing also has Extender Fittings that are used when replacing a standard glued in fitting, valve, etc. Extends the length of the new fitting so it can be re-glued onto the existing pipe. One end of this fitting goes over existing PVC pipe the other fits inside another plumbing fitting. Use this to repair plumbing or replace fittings where at least 1-1/4" of exposed pipe remains.

Tools for Pools Catalog has many problem solving products.

Use of 90 Degree Sweeps

There is no real difference between a 90 degree elbow and a sweep 90 degrees. As long as you keep the water velocity below 6 ft/sec on the suction and below 8 ft/sec on the pressure side of the pump, the difference between a sweep 90 and sharp 90 is minimal.[17]

- Size.......6 ft/sec......8 ft/sec.

- 1.5"...........38...............51 gpm

- 2"..............63...............84 gpm

- 2.5............90.............119 gpm

- 3.0".........138.............184 gpm

Lasco provides the following chart on reduction in head loss for their 90 degree sweeps.[18] While the percentages look significant unless you have many 90 degree turns in the plumbing you will see no operational differences in the performance of your equipment using the sweeps.

PVC Joint Leak Repair

Marine Epoxy

For a leak at a joint on the pressure side near the pump, run the pump and have some "marine epoxy" mixed and ready, then wait for the leak.[19]

Shut off the pump and quickly dry where the leak is. Apply the epoxy immediately.

Once the pump is off, the water in the filter is no longer pressurized wants to fall out, but atmospheric pressure needs to get in for that to happen. This results in a suction situation were the leak is. The atmosphere will "push" the epoxy into the gap where it was leaking. It may take 2 applications.

Let it set for a day before starting pump.

This works like magic, and has fixed leaks that otherwise would have been a major undertaking. Mainly due to access issues.

Look for LOCTITE marine epoxy, widely available. Slathering PVC glue on the joint can also work.

Leak-B-Gone Ring

A member successfully repaired a slow drip joint at a coupler in 2" PVC using “Leak-B-Gone rings”.[20] Essentially little snap on PVC collars that repair bad joints.[21] They may be worth a try before you do more elaborate surgery to a leaking PVC joint.

Leak-B-Gone PVC Pipe Repair rings are intended to permanently repair leaks at PVC pipe joints where the glue has not adhered properly during install, or where the joint has come loose. They are available in seven sizes for between 3/4 in. and 4 in. pipe. Leak-B-Gone rings are easily installed within 60 seconds, as they do not require the use of any outside tool. To install, simply apply primer and cement to the pipe and slide the Leak-B-Gone ring around the leaking pipe joint.

Leak-B-Gone rings can be found at Amazon and Home Depot and other supply stores. You will find videos on YouTube showing its use.

PVC Crack Repairs

Repair products members have used include[22]:

Plast-aid has been used to repair cracks in skimmers and SWGs. It bonds well with PVC, and it's very strong.

The fitting saver or Frankenplug can repair eaking return fittings, skimmer lines, and main drain lines within 14" of a wall:

Painting PVC

Some jurisdictions, like Sacramento County California, require pool PVC to be painted.[23]

Some PVC manufacturers recommend PVC pipes exposed to the direct effects of UV radiation be painted with a light-colored acrylic or latex paint that is chemically compatible with the PVC/CPVC products. Compatibility information should be confirmed with the paint manufacturer. The use of oil-based paints is not recommended.[24]

With painting anything, prep is the key. Scuff with a Scotch Bright pad or sand paper and clean with acetone or alcohol and anything will stick to it.

Paints that people have used include:

- Rustoleum 2X paint and primer in one spray paint that says it is good for plastics

- Krylon Fusion

- BEHR ULTRA Stain-Blocking Paint + Primer in one. Less expensive than spray cans and NO OVERSPRAY on equipment. Once drop cloths are layed down and a bit of masking around the outer edges of the valve housings and compression fittings are complete, it's a breeze and comes out nice.[25]

- "dip your car" type plasti dip/spray and it has a 3 to 10 year UV stable rating.

.

- ↑ https://www.troublefreepool.com/threads/sch-40-dwv-280psi-pvc-question.192390/post-1695456

- ↑ https://www.troublefreepool.com/threads/pool-pipe-collapse-near-skimmer.241543/post-2116867

- ↑ https://www.troublefreepool.com/threads/tx-freeze-jandy-valve-in-awkward-spot-suggestions.224462/post-1968091

- ↑ https://www.troublefreepool.com/threads/uncoupling-existing-pvc-components.193503/post-1705385

- ↑ https://www.troublefreepool.com/threads/hairline-crack-leak-on-pipe-to-chlorinator.266183/post-2329287

- ↑ https://www.troublefreepool.com/threads/check-valve-issues.199283/post-1759645

- ↑ https://www.troublefreepool.com/threads/glue-for-pvc-pipe-into-cpvc-jandy-valve.156350/post-1383484

- ↑ https://www.troublefreepool.com/threads/sch-40-dwv-280psi-pvc-question.192390/post-1696188

- ↑ https://www.oatey.com/PlasticPipeCement

- ↑ https://www.troublefreepool.com/threads/glue-for-pvc-pipe-into-cpvc-jandy-valve.156350/

- ↑ https://www.troublefreepool.com/threads/general-pool-build-questions.241628/post-2118726

- ↑ https://www.troublefreepool.com/threads/cpvc-to-pvc-bonding.180862/#post-1600421

- ↑ https://www.troublefreepool.com/threads/what-should-i-pipe-pump-install-with.178794/#post-1580589

- ↑ https://www.troublefreepool.com/threads/need-advice-on-fiberglass-pool-crack-repair-and-plumbing-replacement.283548/post-2484217

- ↑ https://www.troublefreepool.com/threads/exposed-pvc-pipe-stand-leg-holder.219613/

- ↑ https://www.troublefreepool.com/threads/pvc-parts.183931/

- ↑ https://www.troublefreepool.com/threads/90-degree-vs-180-degree-check-valve-flow-characteristics.197942/post-1747114

- ↑ https://assets.speakcdn.com/assets/1824/sweeps2013.pdf

- ↑ https://www.troublefreepool.com/threads/pvc-fitting-leak.221705/post-1942135

- ↑ https://www.troublefreepool.com/threads/leak-repair-success.200931/post-1773034

- ↑ https://www.homedepot.com/p/Leak-B-Gone-2-in-PVC-Repair-Ring-10-Pack-45035/205346966

- ↑ https://www.troublefreepool.com/threads/cracked-skimmer.266025/post-2327751

- ↑ http://thomasinspections.com/files/Pool_SpaRequirementsSacCounty.pdf

- ↑ https://www.usplastic.com/knowledgebase/article.aspx?contentkey=774

- ↑ https://www.troublefreepool.com/threads/best-quality-pvc-paint.277338/post-2434035