- Nov 12, 2017

- 11,874

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

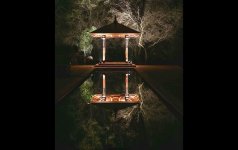

I've mentioned several times over the years my purchase of Volt Lighting for my garden lights. Their build quality is amazing. Beautiful. Solid brass. All sealed up with o-rings. I purchased them almost eight years ago (7 years, 10 months and 12 days ago).

I just had my first and only issue with them. Yah, eight years for low-voltage garden lighting without problems? Unheard of!!

One of my lights was flickering. I emailed VOLT about how best to troubleshoot that. I emailed them on March 1 at about 6:00PM. They responded the same day, Mar 1, 2023, at 4:59 PM! They went back in time to help me! OK, well, that's how their email header read. Maybe some sort of timezone thing I guess, point was, they got back to me FAST!

It took me a day to get around to performing their troubleshooting tip (just took a few minutes), and I responded last night that it appears to only be a bad bulb. I had forgotten that their bulbs have a lifetime guarantee. WHA?!? I just checked my email this morning and a new bulb has already been shipped, no charge.

I mean, come on, who does that?!? I couldn't say enough about the quality of their products before, but they have exemplary customer service to match!

If you're thinking about lighting up your garden (and you should), don't think about using anything other than VOLT.

www.voltlighting.com

www.voltlighting.com

I just had my first and only issue with them. Yah, eight years for low-voltage garden lighting without problems? Unheard of!!

One of my lights was flickering. I emailed VOLT about how best to troubleshoot that. I emailed them on March 1 at about 6:00PM. They responded the same day, Mar 1, 2023, at 4:59 PM! They went back in time to help me! OK, well, that's how their email header read. Maybe some sort of timezone thing I guess, point was, they got back to me FAST!

It took me a day to get around to performing their troubleshooting tip (just took a few minutes), and I responded last night that it appears to only be a bad bulb. I had forgotten that their bulbs have a lifetime guarantee. WHA?!? I just checked my email this morning and a new bulb has already been shipped, no charge.

I mean, come on, who does that?!? I couldn't say enough about the quality of their products before, but they have exemplary customer service to match!

If you're thinking about lighting up your garden (and you should), don't think about using anything other than VOLT.

Factory Direct Landscape Lighting | VOLT® Lighting

Shop VOLT® for easy-to-install landscape lighting fixtures, low voltage transformers and LED outdoor light bulbs with lifetime warranties and fast shipping.

www.voltlighting.com

www.voltlighting.com

Last edited: