I hear you

First... based on advice here I looked in to the need for a fireman's switch, the heater is a Hayward and states it doesn't need one.

Now to the wiring, I pulled off the current switch, it has red, green and blue coming in. Green is ground/earth, red and blue go to the two hot terminals on the switch. Black wires come off the other poles of the switch and go off to the pump.

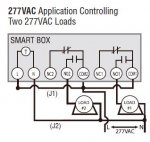

So... I'm pretty sure I have two 110v feeds that are joined up at the pump, i.e. I need to follow the diagram above that shows two 110v coming in to L and N, just need to determine how to run two loads from there, whether to just "pair them up" or not.

First... based on advice here I looked in to the need for a fireman's switch, the heater is a Hayward and states it doesn't need one.

Now to the wiring, I pulled off the current switch, it has red, green and blue coming in. Green is ground/earth, red and blue go to the two hot terminals on the switch. Black wires come off the other poles of the switch and go off to the pump.

So... I'm pretty sure I have two 110v feeds that are joined up at the pump, i.e. I need to follow the diagram above that shows two 110v coming in to L and N, just need to determine how to run two loads from there, whether to just "pair them up" or not.

. The conclusion is that often, contactors and relays can handle a higher amperage across the contacts when the load is resistive (Light / Heat) than when it is inductive (Motor / Motion).

. The conclusion is that often, contactors and relays can handle a higher amperage across the contacts when the load is resistive (Light / Heat) than when it is inductive (Motor / Motion).