Hi Folks,

I see threads talking about tapping to Jandy PDA here and here

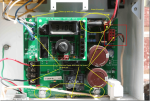

And I was wondering if it is possible to tap into Hayward / Goldline Aquarite unit.

I understand that this is not an automation unit, however if it is possible to at least remotely read the data that can be displayed on the unit.

Things like

And at best to remotely control and change the settings

I see that there is an LED for *Remotely Controlled*

So this should be theoretically possible

Has anyone managed to figured out how to tap to it?

Ideally it would be DIY project, however if there are readily available commercial packages (obviously the cheaper the better) I'm interested to know.

Can any knowledge gathered from the above threads be used to reverse engineer this unit?

Thanks in advance.

I see threads talking about tapping to Jandy PDA here and here

And I was wondering if it is possible to tap into Hayward / Goldline Aquarite unit.

I understand that this is not an automation unit, however if it is possible to at least remotely read the data that can be displayed on the unit.

Things like

- Water temperature

- Salt Level

- Error Codes

- No Flow

- Check Salt

- High Salt

- Inspect Cell

- Current

- Desired Output %

- ...

And at best to remotely control and change the settings

I see that there is an LED for *Remotely Controlled*

So this should be theoretically possible

Has anyone managed to figured out how to tap to it?

Ideally it would be DIY project, however if there are readily available commercial packages (obviously the cheaper the better) I'm interested to know.

Can any knowledge gathered from the above threads be used to reverse engineer this unit?

Thanks in advance.