Apologies in advance for the long post...

Folks, I'm about to have a Class III come-apart...

I'm running a who-knows-how-old Sta-Rite pump. Model number is P4RA5F-125L (as best I can decipher...). More on this later. (EDIT: I deciphered wrong and assumed I knew what I was talking about...)

My 4-year-old 1-1/2 HP pump motor locked up on me last Friday. I ordered a new motor, and also ordered up a new impeller and diffuser, as the old parts were cracked and, I figured, would grenade upon startup of this new motor.

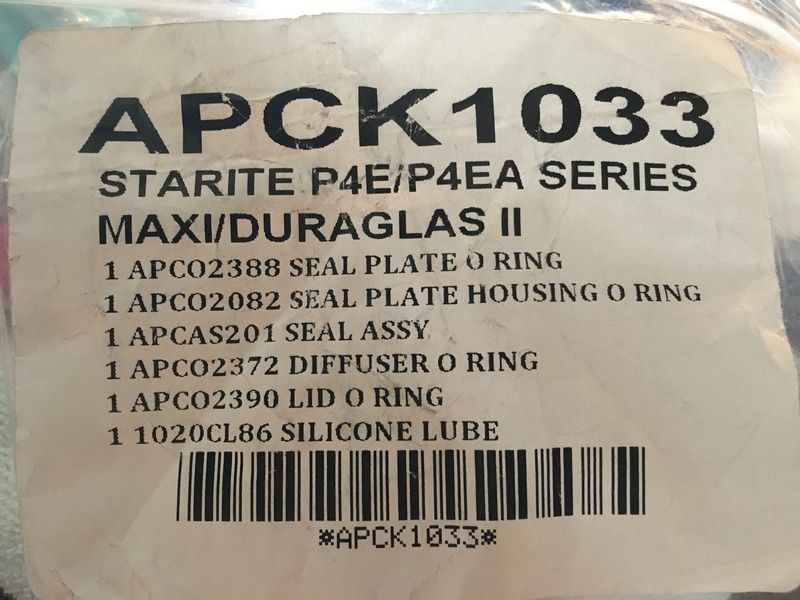

Once I got the pump apart, I realized that all the o-rings were in deplorable condition. So I ordered up a seal kit for a P4E/P4EA pump. What difference does that one letter make, right?

Ha!

Not a single o-ring or seal in that kit will work on my pump. The shaft seals are too big (O.D.), and won't fit the holes they're supposed to go in. The diffuser o-ring is too big (I.D. and O.D.), so it won't sit in the groove for which it's intended.

Searching the 'net for o-rings and seals by pump model reveals that just about everyone lumps the P4E/P4EA/P4R/P4RA pumps together. My seal kit was for a P4E/P4EA, so if it'll fit those pumps, IT WON'T FIT MINE. (EDIT: Because that's not the right model number...)

The other online retailers I've found don't have pictures and/or descriptions of parts. Just part numbers and prices. Yeah. Not helpful.

Further, it seems the pump model I have doesn't even exist. I've found P4RA5F-187L and lots of P4RA6xxx models, but nothing like what my data plate shows.

Does anyone have one of these pumps? Anyone know of a knowledgeable place I can call to find these seals?

I'm really trying not to shell out $500+ for an entirely new pump -- as this one works great (motors are junk...) -- but I'm quickly running out of options. I've been using my TigerShark to circulate water each night when I add my 10% chlorine, and after 7 nights the novelty of it and amazement at the TFP process's ability to keep this pool from becoming a swamp has worn off. Completely.

Thanks in advance for ANY help, advice, words of wisdom, commiseration, etc.

Folks, I'm about to have a Class III come-apart...

I'm running a who-knows-how-old Sta-Rite pump. Model number is P4RA5F-125L (as best I can decipher...). More on this later. (EDIT: I deciphered wrong and assumed I knew what I was talking about...)

My 4-year-old 1-1/2 HP pump motor locked up on me last Friday. I ordered a new motor, and also ordered up a new impeller and diffuser, as the old parts were cracked and, I figured, would grenade upon startup of this new motor.

Once I got the pump apart, I realized that all the o-rings were in deplorable condition. So I ordered up a seal kit for a P4E/P4EA pump. What difference does that one letter make, right?

Ha!

Not a single o-ring or seal in that kit will work on my pump. The shaft seals are too big (O.D.), and won't fit the holes they're supposed to go in. The diffuser o-ring is too big (I.D. and O.D.), so it won't sit in the groove for which it's intended.

Searching the 'net for o-rings and seals by pump model reveals that just about everyone lumps the P4E/P4EA/P4R/P4RA pumps together. My seal kit was for a P4E/P4EA, so if it'll fit those pumps, IT WON'T FIT MINE. (EDIT: Because that's not the right model number...)

The other online retailers I've found don't have pictures and/or descriptions of parts. Just part numbers and prices. Yeah. Not helpful.

Further, it seems the pump model I have doesn't even exist. I've found P4RA5F-187L and lots of P4RA6xxx models, but nothing like what my data plate shows.

Does anyone have one of these pumps? Anyone know of a knowledgeable place I can call to find these seals?

I'm really trying not to shell out $500+ for an entirely new pump -- as this one works great (motors are junk...) -- but I'm quickly running out of options. I've been using my TigerShark to circulate water each night when I add my 10% chlorine, and after 7 nights the novelty of it and amazement at the TFP process's ability to keep this pool from becoming a swamp has worn off. Completely.

Thanks in advance for ANY help, advice, words of wisdom, commiseration, etc.

Last edited: