long story short i've got a rheem m336 pool heater. it's been working fine for years but this year has had some issues. since the beginning of the season, it has intermittently been giving the "spk" error code. you can hear the pilot clicking and upon inspection, you can see a nice blue pilot flame but it continues to click. I had a guy come out and he said it was a bad valve, so i replaced that and no change. same guy comes back out and we determine it must be the board. so i replaced that myself. once i got it all buttoned up i fired her up and after a few minutes of clicking she fired up. i came back an hour later and it had kicked off again. still clicking and still see a nice blue flame. what could it be? my pool company cant come out for two more weeks and this is driving me crazy!!! is it the igniter? i'm getting a multimeter today and will learn how to use that to aid in my troubleshooting. HVAC guy said gas pressure was good and no clogs in the line, but is there a way i can check w/o shutting off gas at the main? if i shut the valve in the heater off can i then remove the pilot/igniter and inspect/clean it? thanks!

Rheem heater not kicking on

- Thread starter roggae

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Oct 25, 2015

- 5,263

- Pool Size

- 25000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

Try cleaning the flame sense rod with a $ bill, no more abrasive than that and also check the connections from the flame sense rod. Fire the repair service you're using. Sounds like they're using trial and error rather than real diagnostics you are paying for.

to be honest it was an HVAC guy who was doing me a favor. i was the one who decided to replace things. he simply did the work for me safely as I am not experienced with natural gas. does this video help at all?Try cleaning the flame sense rod with a $ bill, no more abrasive than that and also check the connections from the flame sense rod. Fire the repair service you're using. Sounds like they're using trial and error rather than real diagnostics you are paying for.

Service Menu and Fault History.

To access the Service Menu and fault history, press the MODE and UP buttons simultaneously for 3 to 5 seconds.

The heater will continue to operate normally while in the Service Menu.

The first screen displayed is the Flame Strength indicator, which indicates the pilot flame current using a bar graph and numerical display.

A signal of less than 4 indicates a weak flame signal and may require service.

Refer to Section 5 – Troubleshooting for possible causes and corrections.

Press the DOWN button.

The Supply Voltage screen indicates the voltage supplied to the control board.

Normal readings range from 24 to 29 volts.

Press the DOWN button. The Run Time indicates the total hours of operation for the pool heater, as measured by the amount of time that the main gas valve has been powered.

The Cycle count indicates the number of on/off cycles of the heater, as measured by the number of times the pilot valve has been powered.

Press the DOWN button. The Fault History can display up to ten faults in memory.

The order of the faults begins with “Fault Last,” which is the most recent fault, and proceeds through ten most recent messages in chronological order.

The second line of the display shows the fault message.

If there are no faults in the history buffer, the second line reads “All Faults Clear.”

Check the above information from the manual.

I suspect that the flame current is too low.

The flame current tells the heater that the flame is good.

If the flame current is too low, the heater thinks that there is a problem.

To access the Service Menu and fault history, press the MODE and UP buttons simultaneously for 3 to 5 seconds.

The heater will continue to operate normally while in the Service Menu.

The first screen displayed is the Flame Strength indicator, which indicates the pilot flame current using a bar graph and numerical display.

A signal of less than 4 indicates a weak flame signal and may require service.

Refer to Section 5 – Troubleshooting for possible causes and corrections.

Press the DOWN button.

The Supply Voltage screen indicates the voltage supplied to the control board.

Normal readings range from 24 to 29 volts.

Press the DOWN button. The Run Time indicates the total hours of operation for the pool heater, as measured by the amount of time that the main gas valve has been powered.

The Cycle count indicates the number of on/off cycles of the heater, as measured by the number of times the pilot valve has been powered.

Press the DOWN button. The Fault History can display up to ten faults in memory.

The order of the faults begins with “Fault Last,” which is the most recent fault, and proceeds through ten most recent messages in chronological order.

The second line of the display shows the fault message.

If there are no faults in the history buffer, the second line reads “All Faults Clear.”

Pool & Spa Heaters - Rheem Pool & Spa Solutions - Rheem Manufacturing Company

Rheem pool heaters provide year-round comfort for your pool or spa and are unmatched in features and benefits. They are designed to make your pool or spa the most comfortable place on earth.

www.rheem.com

Check the above information from the manual.

I suspect that the flame current is too low.

The flame current tells the heater that the flame is good.

If the flame current is too low, the heater thinks that there is a problem.

Raypak PC Board Control Replacement Kit for Digital Gas Heater - 100-10000345 - INYOPools.com

PCB Control Kit - 013464F, Raypak 185B-405B / 206A-408 100-10000345

The flame current proves that the pilot light is good.

You can see the flame current test points on the circuit board.

If the circuit board doesn't get a good flame current reading it will think that the pilot is not on.

The diagnostics can tell you the flame current strength or you can test it directly if you have a good multimeter that can measure dc microamps.

A weak signal can be due to a weak flame, a bad ground, a bad flame sensor or a bad circuit board.

When i did this initially after installing the new board the "flame strength" was 0. is that the same thing?Service Menu and Fault History.

To access the Service Menu and fault history, press the MODE and UP buttons simultaneously for 3 to 5 seconds.

The heater will continue to operate normally while in the Service Menu.

The first screen displayed is the Flame Strength indicator, which indicates the pilot flame current using a bar graph and numerical display.

A signal of less than 4 indicates a weak flame signal and may require service.

Refer to Section 5 – Troubleshooting for possible causes and corrections.

Press the DOWN button.

The Supply Voltage screen indicates the voltage supplied to the control board.

Normal readings range from 24 to 29 volts.

Press the DOWN button. The Run Time indicates the total hours of operation for the pool heater, as measured by the amount of time that the main gas valve has been powered.

The Cycle count indicates the number of on/off cycles of the heater, as measured by the number of times the pilot valve has been powered.

Press the DOWN button. The Fault History can display up to ten faults in memory.

The order of the faults begins with “Fault Last,” which is the most recent fault, and proceeds through ten most recent messages in chronological order.

The second line of the display shows the fault message.

If there are no faults in the history buffer, the second line reads “All Faults Clear.”

Pool & Spa Heaters - Rheem Pool & Spa Solutions - Rheem Manufacturing Company

Rheem pool heaters provide year-round comfort for your pool or spa and are unmatched in features and benefits. They are designed to make your pool or spa the most comfortable place on earth.www.rheem.com

Check the above information from the manual.

I suspect that the flame current is too low.

The flame current tells the heater that the flame is good.

If the flame current is too low, the heater thinks that there is a problem.

i literally replaced my old board with this one yesterday.

Raypak PC Board Control Replacement Kit for Digital Gas Heater - 100-10000345 - INYOPools.com

PCB Control Kit - 013464F, Raypak 185B-405B / 206A-408 100-10000345www.inyopools.com

The flame current proves that the pilot light is good.

You can see the flame current test points on the circuit board.

If the circuit board doesn't get a good flame current reading it will think that the pilot is not on.

The diagnostics can tell you the flame current strength or you can test it directly if you have a good multimeter that can measure dc microamps.

A weak signal can be due to a weak flame, a bad ground, a bad flame sensor or a bad circuit board.

If flame strength is 0 while you have a good pilot flame, the manual indicates that the pilot should be replaced.

Check all grounds to make sure that they are good.

What does the fault history show?

Check all grounds to make sure that they are good.

What does the fault history show?

I managed to get the pilot assembly apart and got a good look at this thing. i assume it's the flame sensor or spark generator. the ceramic base is cracked and the wire looks like it does in the photographs. any thoughts?

If flame strength is 0 while you have a good pilot flame, the manual indicates that the pilot should be replaced.

Check all grounds to make sure that they are good.

What does the fault history show?

oh man! i forgot to do the fault history. i'll put it back together and run it through that procedure. unless you think it would just be smarter to replace the pilot since i've got it all broken down anyway.

swamprat69

Well-known member

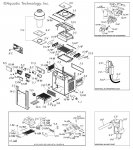

If your pilot assembly looks like the Honeywell atmospheric pilot assembly depicted below, I have always found that the flame signal can be maximized by cleaning to "bare metal" parts of the pilot assembly and burner tray attachments. I have always used a combination of a set of dental picks or a small diamond file set or a small stainless wire brush to scrape the parts to bare metal. The parts that I would clean are underside and edges of the pilot hood ( the part of the pilot assembly that is connected to the pilot tubing. The end of the electrode ( be careful to support the electrode as you file as you don't want movement to crack the ceramic insulator). This will allow the strongest spark by removing any dirt/scale. Next clean the underside of the grounding hood which seems to be shown as 2-P and the pilot assembly mounting plate which seems to be shown as 7-P. Then clean the metal part of the burner tray that the pilot assembly "7-P" screws onto. Finally, make sure that the ground to the burner tray that is outside of the combustion chamber is clean. This should assure the strongest flame signal possible.

swamprat69

Well-known member

If your pilot assembly looks like the Honeywell atmospheric pilot assembly depicted below, I have always found that the flame signal can be maximized by cleaning to "bare metal" parts of the pilot assembly and burner tray attachments. I have always used a combination of a set of dental picks or a small diamond file set or a small stainless wire brush to scrape the parts to bare metal. The parts that I would clean are underside and edges of the pilot hood ( the part of the pilot assembly that is connected to the pilot tubing. The end of the electrode ( be careful to support the electrode as you file as you don't want movement to crack the ceramic insulator). This will allow the strongest spark by removing any dirt/scale. Next clean the underside of the grounding hood which seems to be shown as 2-P and the pilot assembly mounting plate which seems to be shown as 7-P. Then clean the metal part of the burner tray that the pilot assembly "7-P" screws onto. Finally, make sure that the ground to the burner tray that is outside of the combustion chamber is clean. This should assure the strongest flame signal possible.

did as instructed and she fired right up! thank you so very much for all your help/suggestions folks!

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.