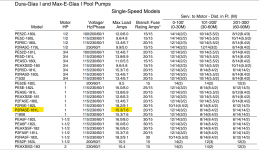

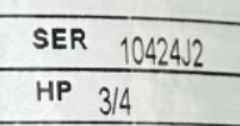

My original pump motor burned up and, being in Florida, the sun faded the label so it was unreadable. I could make out that there was a “2” in the HP field, but I couldn’t tell if there was anything before that number, so it could be 1/2, 1 1/2, or 2. I took the motor to my local Pinch-a-Penny to see if they could identify it and they said it was most likely a 1HP but didn’t specify full-rated vs up-rated. I reached out to Inyo and they recommended choosing a pump that matched the impeller rating. Looking at the part number on the impeller it was rated for a ½ to 3/4 motor.

My pool is a rectangle, no water features, no heater, nothing special, with a cartridge filter. It’s about 18,000 gallons. 2 returns, 1 skimmer, and 1 bottom drain.

I went with the recommendation and got a 1HP motor, but it leaked and had cavitation issues. I was also hesitant because of the impeller rating. I could stop the leak after replacing seals a couple of times so I decided to return that pump and step down to a 3/4HP pump and upgrade the impeller and diffuser to ones that were rated at 3/4.

Now, the pump doesn’t leak but it does run for a few minutes, shuts off for a few minutes, and repeats the cycle, I assume because of thermal overload. I checked the wiring, confirmed that the line output is ~118V and made sure the motor was set to 115 (as opposed to 220V). The motor definitely gets very warm but not so hot that I can’t keep my hand on it. Maybe that’s the intentional design on the thermal protection.

My question is how can I figure out what the problem is? The original motor ran perfectly fine until it burned up, but it was likely the original motor and was 10+ years old. No other changes or modifications were made so it seems like the pump is working too hard? My first thought was to go back to a 1HP motor, but the pressure on the filter gauge with the original motor was around 8PSI and now, with the 3/4HP motor, it stays around 12-15PSI with a clean filter. So it would seem to be that going bigger might increase the pressure, which may or may not be OK. The original impeller being rated for ½ to 3/4 gives me pause too as it seems that a ½ HP motor may be undersized and would have to work that much harder to move the water. At the same time, since I’ve upgraded the impeller and diffuser to match the current motor, wouldn’t that mean that it’s not a flow rate issue?

FWIW, there are also small air bubbles that are coming out of the furthest return jet (none out of the closest one). I’ve turned the valves from the drain and skimmer to see if maybe one of them has some kind of obstruction but none of them made any noticeable change to the bubbles (ideally they would go away when the offending line was closed.

Do you guys have any ideas or recommendations on what to look at next or things to try? I’m almost to a point where I call a service tech but I was unexpectedly laid off so I’m trying to do anything and everything I can do myself before calling them and having to out out the money.

My pool is a rectangle, no water features, no heater, nothing special, with a cartridge filter. It’s about 18,000 gallons. 2 returns, 1 skimmer, and 1 bottom drain.

I went with the recommendation and got a 1HP motor, but it leaked and had cavitation issues. I was also hesitant because of the impeller rating. I could stop the leak after replacing seals a couple of times so I decided to return that pump and step down to a 3/4HP pump and upgrade the impeller and diffuser to ones that were rated at 3/4.

Now, the pump doesn’t leak but it does run for a few minutes, shuts off for a few minutes, and repeats the cycle, I assume because of thermal overload. I checked the wiring, confirmed that the line output is ~118V and made sure the motor was set to 115 (as opposed to 220V). The motor definitely gets very warm but not so hot that I can’t keep my hand on it. Maybe that’s the intentional design on the thermal protection.

My question is how can I figure out what the problem is? The original motor ran perfectly fine until it burned up, but it was likely the original motor and was 10+ years old. No other changes or modifications were made so it seems like the pump is working too hard? My first thought was to go back to a 1HP motor, but the pressure on the filter gauge with the original motor was around 8PSI and now, with the 3/4HP motor, it stays around 12-15PSI with a clean filter. So it would seem to be that going bigger might increase the pressure, which may or may not be OK. The original impeller being rated for ½ to 3/4 gives me pause too as it seems that a ½ HP motor may be undersized and would have to work that much harder to move the water. At the same time, since I’ve upgraded the impeller and diffuser to match the current motor, wouldn’t that mean that it’s not a flow rate issue?

FWIW, there are also small air bubbles that are coming out of the furthest return jet (none out of the closest one). I’ve turned the valves from the drain and skimmer to see if maybe one of them has some kind of obstruction but none of them made any noticeable change to the bubbles (ideally they would go away when the offending line was closed.

Do you guys have any ideas or recommendations on what to look at next or things to try? I’m almost to a point where I call a service tech but I was unexpectedly laid off so I’m trying to do anything and everything I can do myself before calling them and having to out out the money.