- May 3, 2007

- 17,077

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

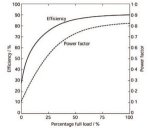

VS pumps maybe but pumps with induction motors have a power factor that varies with load. Usually induction motors don't get much about 0.8-0.9 PF at maximum. This will drop off with an operating point that moves to the left of the head curve.Pumps using a capacitor should have a power factor of about 1.0.

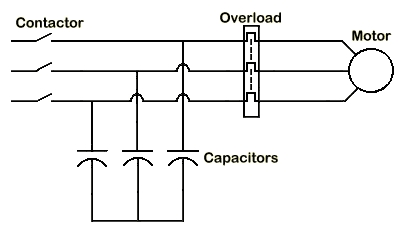

For industrial applications, they will sometimes add a capacitor bank to shift the line current so the facility has a PF of one but that is mandated by the power company. They generally don't require that for residential power.