- Jul 12, 2021

- 62

- Pool Size

- 20000

- Surface

- Vinyl

- Chlorine

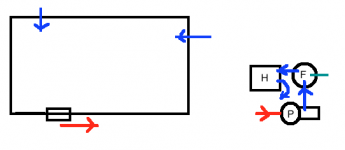

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Hello,

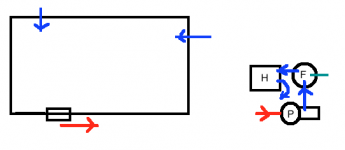

We have a 16 by 32 rectangular pool with 2 returns and 1 skimmer. See picture for location of the lines and the equipment pad.

This year we were thinking of redoing the pool deck/coping because the pavers and are totally uneven/shifted all over the place.

I see this as an opportunity to update the pool a little bit. Answers/advice/opinions to the below questions would be appreciated.

1 - I always felt this pool was lacking 1 more return (maybe 1 more skimmer?) as there is a giant dead spot in the corner closest to the equipment pad. I have considered options such as:

- add a jet to the right of the skimmer (close to equipment pad) to keep water moving in a circle

- move the skimmer closer to the dead spot, and add a jet on the far wall to aim towards it

- add a second skimmer in that corner (can 2 skimmers go on the same pipe underground?)

which do you think would be most beneficial/practical to eliminating the dead spot and improving water flow

2 - there is a single track for the liner, with no trim extending above it. some kind of flagstones make up the coping and they are terrible. Can I add a metal track above it to pour a cantilevered/concrete coping? I saw in the tfp article that you cannot once there is a liner in place, but I wondered if there has been a new product/solution made since then

3 - I would like to add eventually, when the liner is changed, some pre-fab stairs in the dead-spot corner as a way into the water, and to reduce the impact of stagnancy in that spot (something like the picture below)

3 - I would like to add eventually, when the liner is changed, some pre-fab stairs in the dead-spot corner as a way into the water, and to reduce the impact of stagnancy in that spot (something like the picture below)

can this be done without having to affect the pool wall or much structural work?

Thank you in advance for your replies/advice

We have a 16 by 32 rectangular pool with 2 returns and 1 skimmer. See picture for location of the lines and the equipment pad.

This year we were thinking of redoing the pool deck/coping because the pavers and are totally uneven/shifted all over the place.

I see this as an opportunity to update the pool a little bit. Answers/advice/opinions to the below questions would be appreciated.

1 - I always felt this pool was lacking 1 more return (maybe 1 more skimmer?) as there is a giant dead spot in the corner closest to the equipment pad. I have considered options such as:

- add a jet to the right of the skimmer (close to equipment pad) to keep water moving in a circle

- move the skimmer closer to the dead spot, and add a jet on the far wall to aim towards it

- add a second skimmer in that corner (can 2 skimmers go on the same pipe underground?)

which do you think would be most beneficial/practical to eliminating the dead spot and improving water flow

2 - there is a single track for the liner, with no trim extending above it. some kind of flagstones make up the coping and they are terrible. Can I add a metal track above it to pour a cantilevered/concrete coping? I saw in the tfp article that you cannot once there is a liner in place, but I wondered if there has been a new product/solution made since then

3 - I would like to add eventually, when the liner is changed, some pre-fab stairs in the dead-spot corner as a way into the water, and to reduce the impact of stagnancy in that spot (something like the picture below)

3 - I would like to add eventually, when the liner is changed, some pre-fab stairs in the dead-spot corner as a way into the water, and to reduce the impact of stagnancy in that spot (something like the picture below)can this be done without having to affect the pool wall or much structural work?

Thank you in advance for your replies/advice