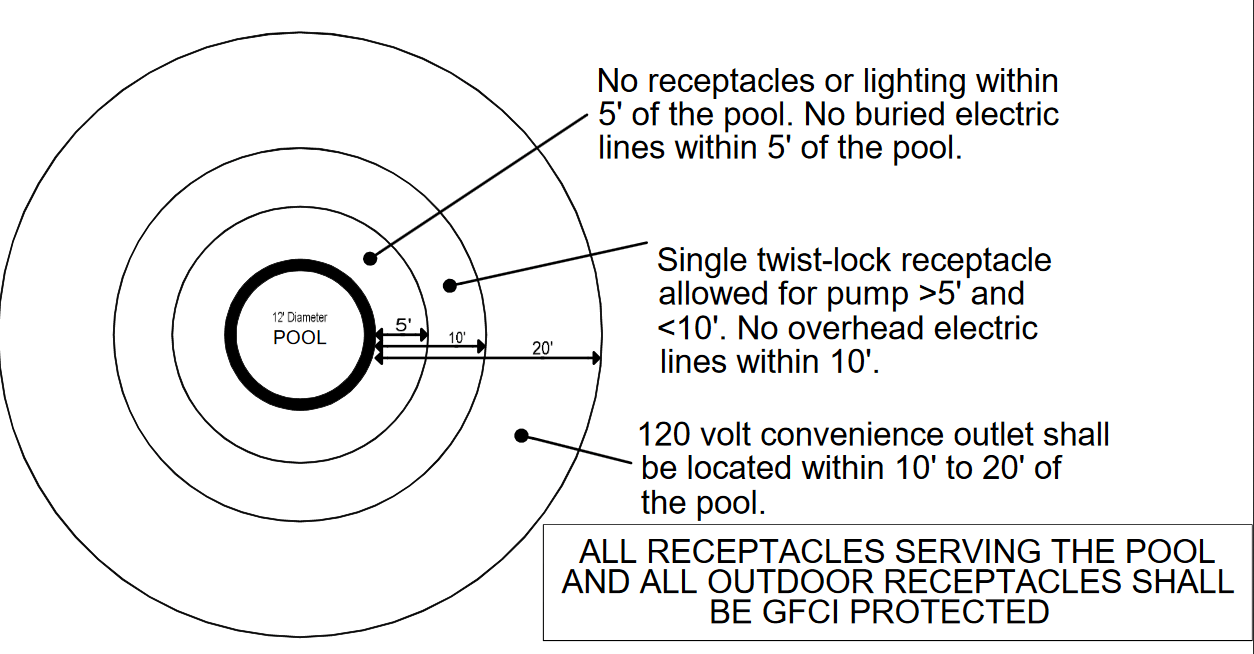

So my motor is a 2hp 2 stage pump that is within 100(around 85ish feet) of my breaker box. I plan on run 3 12 gauge wires in conduit to the pump. I will be using THHN wire as it will be outside. Here is a chart of my pumps motor spec. I will be running a new feed from the panel box to the pool pump and I will use a 20 amp gfci breaker.

I also have a convince outlet thats there now that was powering my intex pool. This is a 15 amp outlet that I used the same 12 gauge THHN and its on a gfci breaker. This is a separate 15 amp breaker than what the ump will use. I will place the new pool s this outlet is farther than 6 feet away but closer than 20 feet. Planning on placing this 7 feet away from the pool as we will use this for our radio.

Bonding is where it gets a little confusing. Bonding consists of running an 8 AWG solid copper "halo" around a pool (18-24" away from pool and buried 4-6" deep) and connecting it with copper lugs and split bolts to metal legs or metal plates of the pool in 4 different places even spaced around the pool. Then you bond the water using a special inline fitting or metal plumbing that comes in contact with the water. Then you bolt the copper wire to the motor lug. Then you coil up the remainder of the wire (a couple of feet coiled into a 12" wide coil is ok) and bury it 4-6 inches underground.

QUESTION 1: Do I need a grounding rod? I was planning on adding one to be safe but most people don't seem to add one?

QUESTION 2: To bond it to the pool legs I plan on using these. It says my pool has galvanized steel uprights so would I simply just drill a hole on 4 uprights and put a bolt into the bonding clamp, I saw some people mention online they just attach with a self tapping galvanized screw? Looks like I will need to do this to 4 legs. My manual has nothing in it about being pre drilled or having bonding points?

Burndy Lay-In Lug Clamshell - Electric Plugs - Amazon.com

QUESTION 3 Now to bond to the water it seems most electricians use the plate that goes into the skimmer box that you have to drill into. The advantage of this is that no water flow will ever be effected but the thought of causing a leak is worrying. Like this.

www.acehardware.com

www.acehardware.com

I am a little nervous about drilling into a brand new pool and found something that will thread on the the skimmer box. My worry with this is it will impede the flow of water and if some debris gets past the skimmer baskets it will get stuck in the bonding plate internal. Any suggestions on which water bond method to use? Molded Products 25810-850-000 Pool Defender Econ Union with Stainless Steel Pool Bond - Walmart.com

QUESTION 4 I plan on adding salt water down the line. Most of the systems I looked at like CircuPool will come on when the pump timer kicks on. Do I need a special timer since my pump is two stage? Can I Simply just attach the salt water controls to the same lugs on the timer as the pump or do the make a timer specific for this? From what I read it seem most just has the standard pool timer and there is a toggle switch on the pump that will allow you to alter the stage. Any reason not to get a smart pool pump timer so i can dork out over it?

or jsut stick with the tried and true mechanical timer?

Thanks so much for all the help. I am a planner and must fully understand every aspect before I will attempt the install.

I also have a convince outlet thats there now that was powering my intex pool. This is a 15 amp outlet that I used the same 12 gauge THHN and its on a gfci breaker. This is a separate 15 amp breaker than what the ump will use. I will place the new pool s this outlet is farther than 6 feet away but closer than 20 feet. Planning on placing this 7 feet away from the pool as we will use this for our radio.

Bonding is where it gets a little confusing. Bonding consists of running an 8 AWG solid copper "halo" around a pool (18-24" away from pool and buried 4-6" deep) and connecting it with copper lugs and split bolts to metal legs or metal plates of the pool in 4 different places even spaced around the pool. Then you bond the water using a special inline fitting or metal plumbing that comes in contact with the water. Then you bolt the copper wire to the motor lug. Then you coil up the remainder of the wire (a couple of feet coiled into a 12" wide coil is ok) and bury it 4-6 inches underground.

QUESTION 1: Do I need a grounding rod? I was planning on adding one to be safe but most people don't seem to add one?

QUESTION 2: To bond it to the pool legs I plan on using these. It says my pool has galvanized steel uprights so would I simply just drill a hole on 4 uprights and put a bolt into the bonding clamp, I saw some people mention online they just attach with a self tapping galvanized screw? Looks like I will need to do this to 4 legs. My manual has nothing in it about being pre drilled or having bonding points?

Burndy Lay-In Lug Clamshell - Electric Plugs - Amazon.com

QUESTION 3 Now to bond to the water it seems most electricians use the plate that goes into the skimmer box that you have to drill into. The advantage of this is that no water flow will ever be effected but the thought of causing a leak is worrying. Like this.

Burndy Water Bonding Ground Kit 1 pk - Ace Hardware

I am a little nervous about drilling into a brand new pool and found something that will thread on the the skimmer box. My worry with this is it will impede the flow of water and if some debris gets past the skimmer baskets it will get stuck in the bonding plate internal. Any suggestions on which water bond method to use? Molded Products 25810-850-000 Pool Defender Econ Union with Stainless Steel Pool Bond - Walmart.com

QUESTION 4 I plan on adding salt water down the line. Most of the systems I looked at like CircuPool will come on when the pump timer kicks on. Do I need a special timer since my pump is two stage? Can I Simply just attach the salt water controls to the same lugs on the timer as the pump or do the make a timer specific for this? From what I read it seem most just has the standard pool timer and there is a toggle switch on the pump that will allow you to alter the stage. Any reason not to get a smart pool pump timer so i can dork out over it?

DEWENWILS Outdoor Smart Wi-Fi Outlet Box, Heavy Duty 40A 120-277 VAC 2HP Wireless Controller Timer Switch for Pool, Water Heater, Compatible with Smart Phone, Alexa, Google Assistant, UL Listed - - Amazon.com

DEWENWILS Outdoor Smart Wi-Fi Outlet Box, Heavy Duty 40A 120-277 VAC 2HP Wireless Controller Timer Switch for Pool, Water Heater, Compatible with Smart Phone, Alexa, Google Assistant, UL Listed - - Amazon.com

www.amazon.com

or jsut stick with the tried and true mechanical timer?

Intermatic T100 Series 40 Amp 125V 24-Hour SPST Mechanical Time Switch with Outdoor Enclosure T101RD89 - The Home Depot

This Intermatic T101R Series SPST Mechanical Time Switch with Outdoor Enclosure dependable time switches can handle electrical loads up to 40 A per pole.

www.homedepot.com

Thanks so much for all the help. I am a planner and must fully understand every aspect before I will attempt the install.

Last edited: