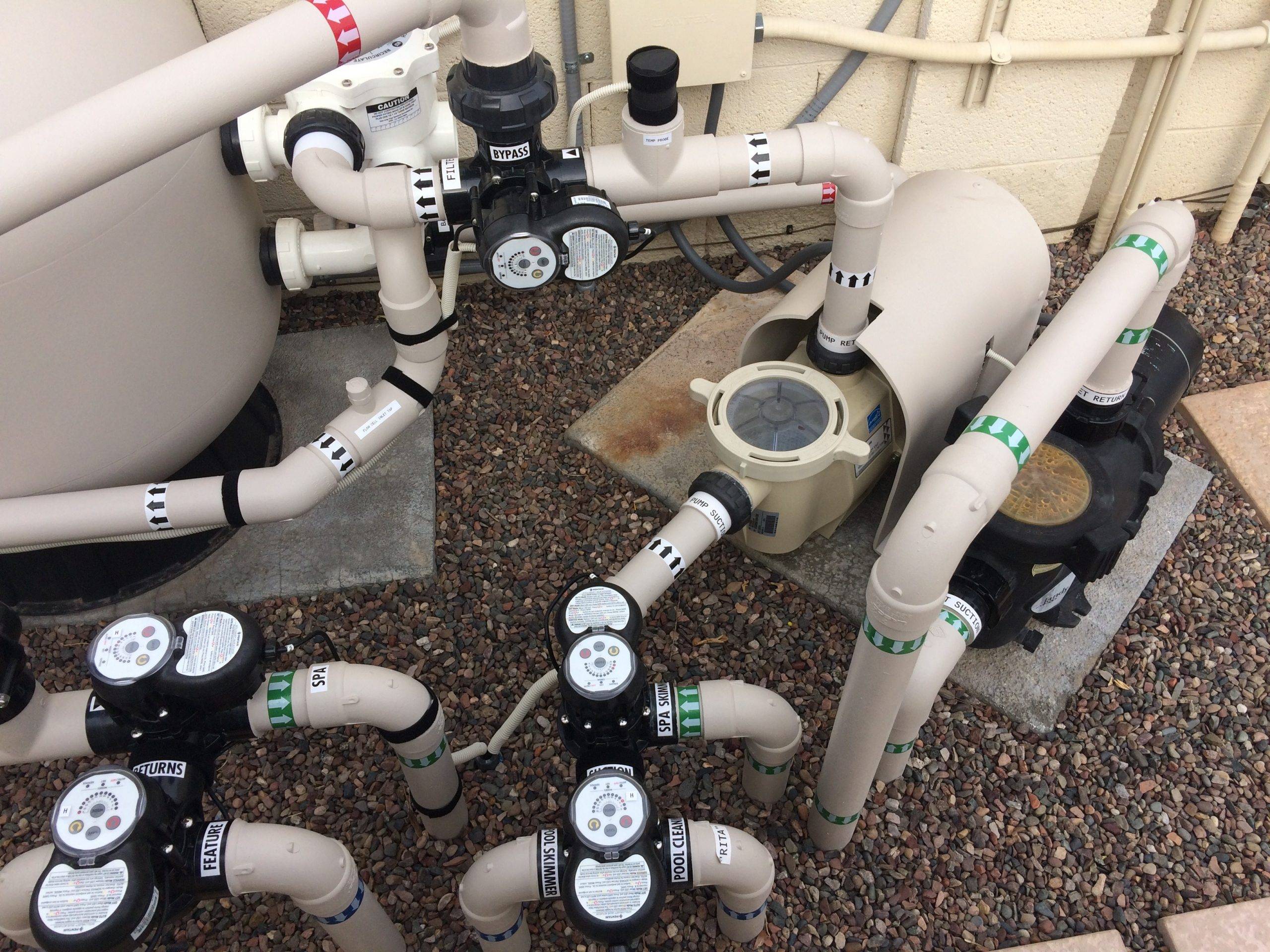

I am trying to figure out the suction side and return pipe sizes of my system. Total gallons in pool is 52k, I have two skimmers, a main drain, and a spa drain to provide return water to 2

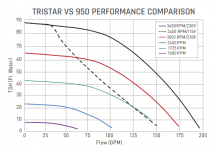

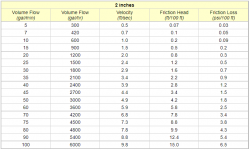

Returns in the spa and 8 in the pool. I am considering the Tristar VS 950 pump and calculated with 2.5 inch pipe for suction and 2.5 for returns I would be at 86tdh which doesn’t seem to work. I would only get about 80gpm at that tdh. This would take over 10 hours to turn the pool once. Do I need to go up to 3 inch pipe? 3 inch suction with 2.5 inch returns would give me about 64tdh and 135 gpm at 3450 rpm. That also puts me near the max of 138 for 6ft/ sec. any help is appreciated. This is an owner build if it isn’t totally obvious. Just trying to make sure I size things properly. I was planning these numbers on 2.5 inch for the returns. If I did 2 inch returns I would have 72tdh and about 110 gpm. Is that sufficient? If I should look at a different pump for this I am not stuck on that particular one. Just want to stick with Hayward.

Returns in the spa and 8 in the pool. I am considering the Tristar VS 950 pump and calculated with 2.5 inch pipe for suction and 2.5 for returns I would be at 86tdh which doesn’t seem to work. I would only get about 80gpm at that tdh. This would take over 10 hours to turn the pool once. Do I need to go up to 3 inch pipe? 3 inch suction with 2.5 inch returns would give me about 64tdh and 135 gpm at 3450 rpm. That also puts me near the max of 138 for 6ft/ sec. any help is appreciated. This is an owner build if it isn’t totally obvious. Just trying to make sure I size things properly. I was planning these numbers on 2.5 inch for the returns. If I did 2 inch returns I would have 72tdh and about 110 gpm. Is that sufficient? If I should look at a different pump for this I am not stuck on that particular one. Just want to stick with Hayward.

Last edited:

To help you with this question, I'm going to tag

To help you with this question, I'm going to tag