- Jun 22, 2014

- 47,854

- Pool Size

- 17888

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

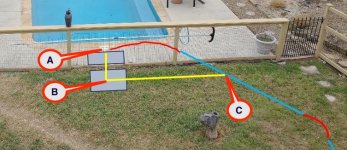

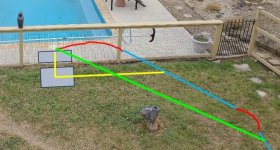

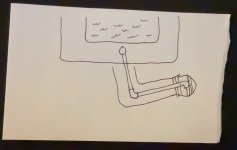

After several months of debate and testing that has confirmed I have plumbing leak on both the pressure and suction sides, I've finally decided to go in. My priority is the suction line right now since I have a Frakenplug installed in my cracked return jet, but since I had to rent a concrete saw w/ a diamond blade and a 70 lb jackhammer, I decided to cut both areas of the deck to save $$$. I'll hold-off digging on the return jets until later. It's too blazing hot. My return jet diagnosis was confirmed in THIS THREAD. While working on my suction side, I have my original suction line bypassed with a temp above-ground line as noted in THIS THREAD.

Below are some starter pics as I begin my adventure. Even with the right tools, it's utterly exhausting. To say I'm beat is an understatement. I think I'll relax for the now and just cut-out the rebar and call it quits for today. More updates to follow.

Below are some starter pics as I begin my adventure. Even with the right tools, it's utterly exhausting. To say I'm beat is an understatement. I think I'll relax for the now and just cut-out the rebar and call it quits for today. More updates to follow.