I have a Pentair Mastertemp 400, installed in 2017. It worked at the end of last season, but when I went to start it up this year it would short cycle. The gas would come on, run for a minute or or so, then shut off for a short bit, another minute or so, and repeat. After several times the "service heater" LED would illuminate.

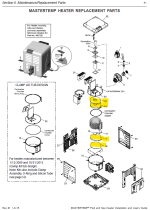

I researched on the web, and the general consensus was that it was either the bypass valve or the thermostat that was bad. I did not get an HLS LED lit on the back of the control board, but I still assumed it was one of these two issues. So I replaced the thermostat first. No change. I tested the old thermostat and the new one in 130 degree water, and they both opened up fine. I then removed the manifold to change the bypass valve. This looked fine, but I went ahead and replaced it anyway. Same problem.

An interesting side note here, which will become important later. The top edge of the manifold was slightly melted. Not enough to damage the inner o-ring seal, so it did not leak. I also noticed that there appeared to be a burn mark on the top of the heater, on the metal plate, right at the edge where the manifold was. My assumption was that some debri from mice had been left on there, and at some point got hot enough to ignite, which made the mark and melted the top lip of the manifold.

My heater has a gas regulator on the outside, which brings down the pressure before entering the heater. It has a vent tube on it. The end of the vent had fallen off of the mount on the wood fencing. I decide to check the vent, and discovered it had water in it. I drained the hose and tried again. This time the heater stayed on continuously. So apparently it was starving for propane. So problem solved, right?

Nope. After several minutes of it running well, I was putting the side panel back on when the pressure sensor on top of the manifold sprung a big leak. So I shut it down. Upon inspection, I discovered that the back side of the pressure switch had a bulge - it had started to melt, which caused it to leak. I now made the assumption that this was damaged/melted at the same time the top lip had gotten damaged from debri burning on top of the heater. I had not noticed any melting of the switch when I replaced the bypass valve, but it is possible I missed it since it never occurred to me to look. I convinced myself that this was already damaged from the fire, and that my jiggling of it when removing the wires and the manifold had pushed it over the edge and it failed.

So I got a new pressure switch and tried again. It started up fine and ran. But after several minutes of running, same thing. Sensor started a slow leak, and I could see that the back of the switch was starting to deform. I touched the top metal plate of the heater and it was extremely hot.

So I shut it down. I felt the top of the manifold to see if that was being affected by the heat as well. It is actually much further from the metal plate than the pressure switch, so it seemed unlikely. It was not soft. So I still contend that this melting was more likely due to the debri fire that had occurred at some point in the past. If it had actually gotten hot enough to cause the manifold to melt due to the current issue, then the pressure switch would have already been leaking/destroyed much worse than it appeared.

So now I am at a loss. If it overheats like this, I would think there would be some safeguard to shut it off. First line of defense is the HLS, which should trigger if the water output gets to >135 degrees. This is backed up by the AGS, which should open at 140 and turn off the gas. Finally, there is the SFS (stack flue sensor). This should sense when the exhaust gas temp gets too high.

So why would all of these fail at once? The HLS and AGS both depend on heated water to pass over them. The thermostat tested fine, but if the thermostat is closed when the heater is started, it prevents any flow through the heating coils since it is blocking it. If there is water in the coils already, it will be sitting against the thermostat, will heat up, and cause it to open. But since I just had the manifold off, there was no water in it anymore. If the thermostat is closed, how does the air in the heating tubes get out? Does it count on the thermostat to be leaky so the air can get pushed out? This vapor lock would prevent both the HLS and AGS from doing their jobs. What about the SFS? Would the exhaust gas temp increase dramatically under this overheating condition, such that it would sense a problem? Clearly it did not.

I checked the sensors. The HLS and AGS are both normally closed, and I validated this with a meter. So if they are failing, they are stuck NC. I did not take a measurement across the SFS, but I did push and hold the ON button, and it displayed the approximate air temp when the heater was off and cool. BTW - the input water temp displayed looks accurate, so the thermistor is OK. I also measure the thermistor, and it was 7.3k, which is about right for a 10k NTC thermistor.

I am not sure what to do next. I ordered all new sensors. If the sensors were bad sensor, new ones will cause it to properly shut itself down, but not actually fix the problem. Neither of these sensors is part of the normal control loop - they are just there as safeguards. The mechanical thermostat and bypass valve are supposed to regulate the temperature and water flow.

The problem seems to be indicative of a flow issue. Flow is controlled by the bypass valve and thermostat. Both of them seem OK. There are 6 tubes that go through the heater. I did not try running water or air through any of them when the manifold was off, but they did look very clean with no debri on them or corrosion of the openings. How about if I remove the thermostat to see if it still overheats? At least this would guarantee unobstructed flow and eliminate any issue due to the thermostat, such as vapor lock or a bad thermostat.

One more item, in the interest of full disclosure. I did replace the pool pump at the beginning o the season. The old one still ran, but the bearings were so shot after 22 years of use that the noise was untenable. I replaced it with the same size motor. The water output seems as good, or better, than ever, as indicated by the amount of water going over the spillway out of my hot tub.

I do not have an external bypass path around the heater. So for sure all of the water flow is entering and exiting the heater.

Sorry for the log winded explanation, but I wanted to be thorough. Any ideas of what the hec is going on here? Next steps?

I researched on the web, and the general consensus was that it was either the bypass valve or the thermostat that was bad. I did not get an HLS LED lit on the back of the control board, but I still assumed it was one of these two issues. So I replaced the thermostat first. No change. I tested the old thermostat and the new one in 130 degree water, and they both opened up fine. I then removed the manifold to change the bypass valve. This looked fine, but I went ahead and replaced it anyway. Same problem.

An interesting side note here, which will become important later. The top edge of the manifold was slightly melted. Not enough to damage the inner o-ring seal, so it did not leak. I also noticed that there appeared to be a burn mark on the top of the heater, on the metal plate, right at the edge where the manifold was. My assumption was that some debri from mice had been left on there, and at some point got hot enough to ignite, which made the mark and melted the top lip of the manifold.

My heater has a gas regulator on the outside, which brings down the pressure before entering the heater. It has a vent tube on it. The end of the vent had fallen off of the mount on the wood fencing. I decide to check the vent, and discovered it had water in it. I drained the hose and tried again. This time the heater stayed on continuously. So apparently it was starving for propane. So problem solved, right?

Nope. After several minutes of it running well, I was putting the side panel back on when the pressure sensor on top of the manifold sprung a big leak. So I shut it down. Upon inspection, I discovered that the back side of the pressure switch had a bulge - it had started to melt, which caused it to leak. I now made the assumption that this was damaged/melted at the same time the top lip had gotten damaged from debri burning on top of the heater. I had not noticed any melting of the switch when I replaced the bypass valve, but it is possible I missed it since it never occurred to me to look. I convinced myself that this was already damaged from the fire, and that my jiggling of it when removing the wires and the manifold had pushed it over the edge and it failed.

So I got a new pressure switch and tried again. It started up fine and ran. But after several minutes of running, same thing. Sensor started a slow leak, and I could see that the back of the switch was starting to deform. I touched the top metal plate of the heater and it was extremely hot.

So I shut it down. I felt the top of the manifold to see if that was being affected by the heat as well. It is actually much further from the metal plate than the pressure switch, so it seemed unlikely. It was not soft. So I still contend that this melting was more likely due to the debri fire that had occurred at some point in the past. If it had actually gotten hot enough to cause the manifold to melt due to the current issue, then the pressure switch would have already been leaking/destroyed much worse than it appeared.

So now I am at a loss. If it overheats like this, I would think there would be some safeguard to shut it off. First line of defense is the HLS, which should trigger if the water output gets to >135 degrees. This is backed up by the AGS, which should open at 140 and turn off the gas. Finally, there is the SFS (stack flue sensor). This should sense when the exhaust gas temp gets too high.

So why would all of these fail at once? The HLS and AGS both depend on heated water to pass over them. The thermostat tested fine, but if the thermostat is closed when the heater is started, it prevents any flow through the heating coils since it is blocking it. If there is water in the coils already, it will be sitting against the thermostat, will heat up, and cause it to open. But since I just had the manifold off, there was no water in it anymore. If the thermostat is closed, how does the air in the heating tubes get out? Does it count on the thermostat to be leaky so the air can get pushed out? This vapor lock would prevent both the HLS and AGS from doing their jobs. What about the SFS? Would the exhaust gas temp increase dramatically under this overheating condition, such that it would sense a problem? Clearly it did not.

I checked the sensors. The HLS and AGS are both normally closed, and I validated this with a meter. So if they are failing, they are stuck NC. I did not take a measurement across the SFS, but I did push and hold the ON button, and it displayed the approximate air temp when the heater was off and cool. BTW - the input water temp displayed looks accurate, so the thermistor is OK. I also measure the thermistor, and it was 7.3k, which is about right for a 10k NTC thermistor.

I am not sure what to do next. I ordered all new sensors. If the sensors were bad sensor, new ones will cause it to properly shut itself down, but not actually fix the problem. Neither of these sensors is part of the normal control loop - they are just there as safeguards. The mechanical thermostat and bypass valve are supposed to regulate the temperature and water flow.

The problem seems to be indicative of a flow issue. Flow is controlled by the bypass valve and thermostat. Both of them seem OK. There are 6 tubes that go through the heater. I did not try running water or air through any of them when the manifold was off, but they did look very clean with no debri on them or corrosion of the openings. How about if I remove the thermostat to see if it still overheats? At least this would guarantee unobstructed flow and eliminate any issue due to the thermostat, such as vapor lock or a bad thermostat.

One more item, in the interest of full disclosure. I did replace the pool pump at the beginning o the season. The old one still ran, but the bearings were so shot after 22 years of use that the noise was untenable. I replaced it with the same size motor. The water output seems as good, or better, than ever, as indicated by the amount of water going over the spillway out of my hot tub.

I do not have an external bypass path around the heater. So for sure all of the water flow is entering and exiting the heater.

Sorry for the log winded explanation, but I wanted to be thorough. Any ideas of what the hec is going on here? Next steps?