- Jun 5, 2010

- 27

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair iChlor 30

I opened my pool this year to a malfunctioning LCD screen (and 2 broken CVA-24 actuators. but I'll save that for a different thread)

I called Pentair and was told that I needed to replace the entire mother board on the panel.

I'm asking you guys for better advise!!! HA!

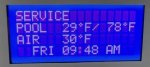

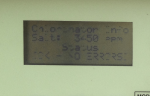

I've attached a picture of the bad screen.

Please tell me I don't have to spend $300-$500 on an entire mother board to fix this!!!

Thanks in advance

Lou ...

I called Pentair and was told that I needed to replace the entire mother board on the panel.

I'm asking you guys for better advise!!! HA!

I've attached a picture of the bad screen.

Please tell me I don't have to spend $300-$500 on an entire mother board to fix this!!!

Thanks in advance

Lou ...