- Feb 28, 2022

- 10

- Pool Size

- 14700

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

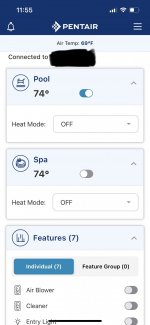

Hi everyone, I just recently built my first gunite pool and have done tons of research on TFP already to learn as much as I can about it, but I have various questions that I was hoping some folks could help me with. Before I get into it, my pool equipment and specs are as follows: 17k gal pool with spa that has hidden spillway, Pentair IntelliFlo3 pump for pool/spa, Pentair WhisperFlo pump for water feature, Pentair Clean & Clear Plus 520 cartridge filter, Pentair MasterTemp 400 heater, Pentair IntelliChlor IC40 SWCG, Silencer Air Blower, A&A Automated In-Floor Cleaning System with 20-something heads (some are Venturi heads, others are the lower-flow heads), Pentair IntelliCenter Automation, and lastly not sure which skimmer I have. I’ve also attached lots of pictures to hopefully give you a complete idea of the setup.

1. Do all of my valves look like they’re turned the right way for the proper setup of my system? What exactly does each one do? For instance, I don’t understand the jandy valve that’s like tilted diagonally left of the word “skimmer” toward the word “pool.”

2. When the start-up guy was walking me through the bare basics of everything, he said my IntelliFlo3 is variable speed and flow, but to not bother adjusting the flow at all. How do I know if I have the right flow settings? What can changing the flow do for me?

3. From my understanding, I cannot have the returns in my pool going while my IFCS is running; the only reason to have the returns going is if the IFCS system is down temporarily. Is this true?

4. In the IntelliCenter app, I can either have the Pool or Spa on, but not both at the same time. One of the plumber guys said it had something to do with not having both the pool drain and spa drain running at the same time. Why is that?

5. In the IntelliCenter app, I was told the “pool” switch controls the main drain and the “cleaner” switch is what turns on the IFCS. Is the “cleaner” switch basically just ramping up the RPM to the main pump, or is it actually turning some valve when I switch it on? Also should I always have “pool” switched on when “cleaner” is switched on? Note that I can have both the pool and cleaner switches on simultaneously.

6. When my pump is running at anything lower than roughly 1800 RPM, I notice the skimmer basket doesn’t stay in the hole and instead floats to the top of the water. Does that mean I need to have the RPM at least that high for any skimming to actually be happening?

7. Going off of Q3 and Q4, if I just have “pool” switched on and at 1200-1500 RPM for part of the day, is the water still circulating sufficiently?

8. How do I know if my IFCS heads are optimally installed? I believe they used the Venturi heads for the ones deeper in the pool, and the other lower-flow heads in the shallower parts like on steps. I’ve noticed that some of the heads also make a loud whining noise when they’re popped up and shooting out water. Would taking them out and switching it to one of the larger or smaller holes fix that? I know you can like rotate a piece on them to change it somehow.

9. The spa has 8 jets around it. Whenever I turn “jets” on and the RPM is ramped up to 3350 RPM, only about 4 actually have a good amount of pressure coming out while the other 4 have next to none. However, if I turn the blower on, all 8 look fine. I believe a plumber came out already to check for debris, but assuming he actually cleaned them out, it didn’t fix the problem. Is there anything else I can do to have good, even pressure for all 8, or am I screwed because of the way it’s plumbed? In the picture of the spa, the 4 that have good pressure without the blower are the 3 jets on the right side and the top jet. Note that my equipment pad is on the opposite (back left) corner of my yard.

Apologies for all the questions already, but I knew nothing about pools until a few weeks ago and have been reading up as much as I can. I’m sure there were a few other questions, but these were the ones I could remember off the top of my head for now. Appreciate any help!

1. Do all of my valves look like they’re turned the right way for the proper setup of my system? What exactly does each one do? For instance, I don’t understand the jandy valve that’s like tilted diagonally left of the word “skimmer” toward the word “pool.”

2. When the start-up guy was walking me through the bare basics of everything, he said my IntelliFlo3 is variable speed and flow, but to not bother adjusting the flow at all. How do I know if I have the right flow settings? What can changing the flow do for me?

3. From my understanding, I cannot have the returns in my pool going while my IFCS is running; the only reason to have the returns going is if the IFCS system is down temporarily. Is this true?

4. In the IntelliCenter app, I can either have the Pool or Spa on, but not both at the same time. One of the plumber guys said it had something to do with not having both the pool drain and spa drain running at the same time. Why is that?

5. In the IntelliCenter app, I was told the “pool” switch controls the main drain and the “cleaner” switch is what turns on the IFCS. Is the “cleaner” switch basically just ramping up the RPM to the main pump, or is it actually turning some valve when I switch it on? Also should I always have “pool” switched on when “cleaner” is switched on? Note that I can have both the pool and cleaner switches on simultaneously.

6. When my pump is running at anything lower than roughly 1800 RPM, I notice the skimmer basket doesn’t stay in the hole and instead floats to the top of the water. Does that mean I need to have the RPM at least that high for any skimming to actually be happening?

7. Going off of Q3 and Q4, if I just have “pool” switched on and at 1200-1500 RPM for part of the day, is the water still circulating sufficiently?

8. How do I know if my IFCS heads are optimally installed? I believe they used the Venturi heads for the ones deeper in the pool, and the other lower-flow heads in the shallower parts like on steps. I’ve noticed that some of the heads also make a loud whining noise when they’re popped up and shooting out water. Would taking them out and switching it to one of the larger or smaller holes fix that? I know you can like rotate a piece on them to change it somehow.

9. The spa has 8 jets around it. Whenever I turn “jets” on and the RPM is ramped up to 3350 RPM, only about 4 actually have a good amount of pressure coming out while the other 4 have next to none. However, if I turn the blower on, all 8 look fine. I believe a plumber came out already to check for debris, but assuming he actually cleaned them out, it didn’t fix the problem. Is there anything else I can do to have good, even pressure for all 8, or am I screwed because of the way it’s plumbed? In the picture of the spa, the 4 that have good pressure without the blower are the 3 jets on the right side and the top jet. Note that my equipment pad is on the opposite (back left) corner of my yard.

Apologies for all the questions already, but I knew nothing about pools until a few weeks ago and have been reading up as much as I can. I’m sure there were a few other questions, but these were the ones I could remember off the top of my head for now. Appreciate any help!

Attachments

-

A65C8406-ECD0-4EA5-965A-C3CBCBF77E30.jpeg824.5 KB · Views: 49

A65C8406-ECD0-4EA5-965A-C3CBCBF77E30.jpeg824.5 KB · Views: 49 -

C12B0D67-BD3F-4582-9E95-CE4D25AF8CD2.png337.5 KB · Views: 44

C12B0D67-BD3F-4582-9E95-CE4D25AF8CD2.png337.5 KB · Views: 44 -

E284931C-C67C-4B18-865C-0942A0DB1A54.jpeg119.9 KB · Views: 47

E284931C-C67C-4B18-865C-0942A0DB1A54.jpeg119.9 KB · Views: 47 -

7988FE91-AA1E-433E-A6A2-5B6B9720334B.jpeg691.3 KB · Views: 53

7988FE91-AA1E-433E-A6A2-5B6B9720334B.jpeg691.3 KB · Views: 53 -

31696BE4-D3D6-474D-A83B-3CEECECFFA45.jpeg560.7 KB · Views: 54

31696BE4-D3D6-474D-A83B-3CEECECFFA45.jpeg560.7 KB · Views: 54 -

E9E9E0BD-5174-4D5E-8C5D-CA7F5E75417D.jpeg721.6 KB · Views: 57

E9E9E0BD-5174-4D5E-8C5D-CA7F5E75417D.jpeg721.6 KB · Views: 57 -

6068C08F-C800-4F5A-9444-7DCD7AF1D6C9.jpeg783 KB · Views: 59

6068C08F-C800-4F5A-9444-7DCD7AF1D6C9.jpeg783 KB · Views: 59 -

6B7578FA-0756-4F89-9253-FCC28B96F0C9.jpeg1 MB · Views: 56

6B7578FA-0756-4F89-9253-FCC28B96F0C9.jpeg1 MB · Views: 56 -

2ACDF088-67AE-4083-B156-25B3A77ED879.jpeg714.1 KB · Views: 39

2ACDF088-67AE-4083-B156-25B3A77ED879.jpeg714.1 KB · Views: 39 -

E61DB211-9C7C-4F48-B6BE-DCA985E3BC4F.jpeg771.7 KB · Views: 45

E61DB211-9C7C-4F48-B6BE-DCA985E3BC4F.jpeg771.7 KB · Views: 45

Last edited: