A 4to5" thick form is what I use with fibermesh concrete out of a redimix truck. I make it 1.5" narrower than coping depth to account for overhang amd I dont want the deck on it I want the coping overhanging a hair on the backside over the base material so easier to screed for deck. I use cement board on top of wall to account for liner track or mesh with a scratch coat. I use laticrete 254 for all my coping adhesion

New DIY Build Underway

- Thread starter Tbwonder

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A 4to5" thick form is what I use with fibermesh concrete out of a redimix truck. I make it 1.5" narrower than coping depth to account for overhang amd I dont want the deck on it I want the coping overhanging a hair on the backside over the base material so easier to screed for deck. I use cement board on top of wall to account for liner track or mesh with a scratch coat. I use laticrete 254 for all my coping adhesion

PERFECT!

Use Laticrete for stone on top of the cantilever plastic step also...or do you use an adhesive there?

Just a bead or two of concrete adhesive like srw or PL masonry. Go heavy amd let it squish as you set coping just stay back with thinset amd glues from the liner track. Dont need it squishing out the front its plenty strong with 80% or more coverage from the back forward. The concrete collar is my main base, the walls are just some added strength for bonus. The collar locks the walls it gets under and around the framing

Jimmy the steel mesh....do you zip screw this to the steel top flange and then out over the seam with the concrete? or just embed it with the laticrete?

Same if I did cement board....screw to steal...and then out and over the seam with concrete?

Gotta find some pictures of this....don't wanna screw this part.

Same if I did cement board....screw to steal...and then out and over the seam with concrete?

Gotta find some pictures of this....don't wanna screw this part.

A 4to5" thick form is what I use with fibermesh concrete out of a redimix truck. I make it 1.5" narrower than coping depth to account for overhang amd I dont want the deck on it I want the coping overhanging a hair on the backside over the base material so easier to screed for deck. I use cement board on top of wall to account for liner track or mesh with a scratch coat. I use laticrete 254 for all my coping adhesion

Find TEK brand screws, you dont want regular screws they will rot. I get them at lowes they are ceramic self tappers. Depending what track you have determines the approach. Most are 3/8" high so 1/4 cement board or lath is fine. For taller half inch board is best. Just on the wall no overlap. Take ur time on the form for coping and make it a hair under the depth of coping minus overhang.

You have liner over stairs or fiberglass?

You have liner over stairs or fiberglass?

Find TEK brand screws, you dont want regular screws they will rot. I get them at lowes they are ceramic self tappers. Depending what track you have determines the approach. Most are 3/8" high so 1/4 cement board or lath is fine. For taller half inch board is best. Just on the wall no overlap. Take ur time on the form for coping and make it a hair under the depth of coping minus overhang.

You have liner over stairs or fiberglass?

Fiberglass cantilever step so the stones go in top of stair.

ok so screw board or lathe....then scratch coat over the board/lathe and concrete foundation and drop the stone.

I mean I installed this whole pool completely solo....this should be in my wheel house. Just wish I could see it.

thanks for all the help always.

Hopefully you raised the stairs to the height of the track. That's the biggest DIY mistake they dont tell you. If you flush stairs to top of the wall theres a huge gap under coping stones when installed. Pain to rectify

So basically you want a form that is slightly under coping depth. Example of 12" coping. You have a 1.5" overhang so 10.5 left over. Wall is let's say 5" top cap. So form should be 5" out from wall but will be 10" to sheetmetal face as concrete will be up under the cap and in the frame. You want coping to overhang the concrete a hair, not the deck onto the collar a hair, you want them separated at that junction in case deck sinks or vice versa you dont get a teeter totter. I do 5" thick usually and add fibermesh always. Good mix too like 3500 or 4000psi and always add plasticizer so it flows great. You want the top of form slightly below the mesh or cement board as you want room to mud up to the height you need, and room for pitch away from pool on coping. I use a piece of 12" 3/8 rebar bent like a boomerang in the top hole where panels connect as that seam makes the collar thin in those spots, makes me sleep better. Laticrete 254 for my coping mud, either .25 or .33 gap for the coping stones, type S for grout. I use tile spacers I am OCD. What shape is pool I can give u radius degrees for cuts if you need them on a rectangle setup. I avoid corners on coping I make 45s so kids dont bust their heads open

So basically you want a form that is slightly under coping depth. Example of 12" coping. You have a 1.5" overhang so 10.5 left over. Wall is let's say 5" top cap. So form should be 5" out from wall but will be 10" to sheetmetal face as concrete will be up under the cap and in the frame. You want coping to overhang the concrete a hair, not the deck onto the collar a hair, you want them separated at that junction in case deck sinks or vice versa you dont get a teeter totter. I do 5" thick usually and add fibermesh always. Good mix too like 3500 or 4000psi and always add plasticizer so it flows great. You want the top of form slightly below the mesh or cement board as you want room to mud up to the height you need, and room for pitch away from pool on coping. I use a piece of 12" 3/8 rebar bent like a boomerang in the top hole where panels connect as that seam makes the collar thin in those spots, makes me sleep better. Laticrete 254 for my coping mud, either .25 or .33 gap for the coping stones, type S for grout. I use tile spacers I am OCD. What shape is pool I can give u radius degrees for cuts if you need them on a rectangle setup. I avoid corners on coping I make 45s so kids dont bust their heads open

Thanks Jimmy,

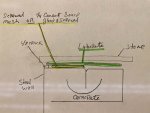

Attaching pic of pool again and a sketch of what I think I am doing based on what you've said.

Yes, the step is set at the level of the track. Royal Swimming Pools sales guy gave me that tip.

This is a rectangle with 6" radius corners. I agree with doing it with 45 pieces instead of hard corners on the pool and steps also.....so heck YES if you have those angles that would be a win for me.

Is the mesh/cement board because the laticrete doesn't adhere as well to the steel?

If I did cement board I could PL it and screw it....but that seems to leave a much thinner bed of thinset to adhere the stone than embedding the mesh with the thinset monolithically and dropping the stone all together. Does this matter either way?

Should the stone rest essentially ON the track on the inside? Once set do you do anything to the corner of the stone and track on the inside of the pool like silicone or anything?

Thanks....think I'm close to having command of this.

David

Attaching pic of pool again and a sketch of what I think I am doing based on what you've said.

Yes, the step is set at the level of the track. Royal Swimming Pools sales guy gave me that tip.

This is a rectangle with 6" radius corners. I agree with doing it with 45 pieces instead of hard corners on the pool and steps also.....so heck YES if you have those angles that would be a win for me.

Is the mesh/cement board because the laticrete doesn't adhere as well to the steel?

If I did cement board I could PL it and screw it....but that seems to leave a much thinner bed of thinset to adhere the stone than embedding the mesh with the thinset monolithically and dropping the stone all together. Does this matter either way?

Should the stone rest essentially ON the track on the inside? Once set do you do anything to the corner of the stone and track on the inside of the pool like silicone or anything?

Thanks....think I'm close to having command of this.

David

Attachments

No difference either works great. I run 2 beads on steel wall of glue then screw with TEKS with board. I never sit on track I stay a hair above unless I have the time to go around with a 6' level amd be sure it's dead flat. On a 6" radius you can get away with it except the corners must be checked well. They can open up from the extreme bend on track channel. I caulk the baby gap by taping off both sides and wet wiping matching tile caulk or colored silicone, depends on coping material

What size coping? Does your corner have an insert that clips two 90degree panels for the radius look?

What size coping? Does your corner have an insert that clips two 90degree panels for the radius look?

Thanks for pictures. Corners are nice.No difference either works great. I run 2 beads on steel wall of glue then screw with TEKS with board. I never sit on track I stay a hair above unless I have the time to go around with a 6' level amd be sure it's dead flat. On a 6" radius you can get away with it except the corners must be checked well. They can open up from the extreme bend on track channel. I caulk the baby gap by taping off both sides and wet wiping matching tile caulk or colored silicone, depends on coping material

What size coping? Does your corner have an insert that clips two 90degree panels for the radius look?

coping stone is 12” x 24”. Will need to cut a 45 piece to bridge across the 6” radius...and at the inside/outside corners of step. Will figure out the angles.

this pool construct is a rectangle, the track is curved for 6” radius and there is a foam filler piece that fits in the corner and beneath the track to support the liner at the 6” radius.

Feeling pretty good now. Just gonna keep staring at it for a bit until it all gels in my head.

I mean...I installed the entire pool as a solo act....I’ve done my other patio in pavers. It’s just the coping that’s been the monkey on my back. Once I get started I’m sure it’ll go fine.

With larger coping like that what I've done is used a piece clipped to make the 45 inside and run it back to be a whole corner piece. Then butt full coping to them on each side. I've also made a sliver for the inside corner and 45'd one side of a full coping to meet that. Usually with larger coping you want a bigger piece for the cuts so it flows better overall

Yup that’s what I am envisioning.With larger coping like that what I've done is used a piece clipped to make the 45 inside and run it back to be a whole corner piece. Then butt full coping to them on each side. I've also made a sliver for the inside corner and 45'd one side of a full coping to meet that. Usually with larger coping you want a bigger piece for the cuts so it flows better overall

Hard to estimate the laticrete....any rough guess how many bags of laticrete for an 18x36?

Looking to get delivery next week sometime. Start in next 2-3 weeks.

I use 5 to 6 bags average with a heavy bed like 3/8 to half inch on that size. The grey is cheaper if u can find it rather than white. Look around tho some places are nuts I was short a bag last fall and the nearest tile joint wanted 70+ for a bag I pay 42ish from my local place. Also mapai makes an outdoor rated that's cheaper as do others. Just be sure its outdoor rated whatever you use.

Ok. On the hunt for this and ceramic coated tek screws. Lowe’s here doesn’t have and have poked around online to no avail. Sink or stainless is all I’ve found. Think stainless rots here?

Stainless is ok just have to be careful they're soft. They make not be ceramic coated maybe composite. I have some in my truck I'll snap a pic 2moro. They are Teks brand. For wood to metal applications

Teks 10 x 1-7/16 in. Philips Flat Head Self Tapping with Wings Screws (100-Pack) 21380 - The Home Depot

Find the Teks #10 x 1-7/16 in. Zinc-Plated Steel Flat-Head Phillips Self-Tapping Screws with Wings (100-Pack) 21380, fasteners can be used to attach wood headers and plywood to steel frames from The Home

www.homedepot.com

This kind but shorter like 1 1/4 I beleive and they are ceramic coated. Never seen them at depot, lowes here has them but green label I believe is the coated ones. They have them on their site and Google hits. They have the wings like these makes a countersink in the cement board nicely

I’m gonna use the mesh with the laticrete. Same screw fine I assume.

Teks 10 x 1-7/16 in. Philips Flat Head Self Tapping with Wings Screws (100-Pack) 21380 - The Home Depot

Find the Teks #10 x 1-7/16 in. Zinc-Plated Steel Flat-Head Phillips Self-Tapping Screws with Wings (100-Pack) 21380, fasteners can be used to attach wood headers and plywood to steel frames from The Homewww.homedepot.com

This kind but shorter like 1 1/4 I beleive and they are ceramic coated. Never seen them at depot, lowes here has them but green label I believe is the coated ones. They have them on their site and Google hits. They have the wings like these makes a countersink in the cement board nicely

Thanks for this.

Have collected everything mostly. Stone and material delivery coming Wednesday....shooting to start working on the coping next weekend.

One last question on the Laticrete 254 (which I already have). The coping stone is 12"x24"...paver thickness. Not crushing but still has some weight to it. Is the 254 ok for this.....or should I have used something for a large format?

Thanks again....will post some progress pics as they come.

One last question on the Laticrete 254 (which I already have). The coping stone is 12"x24"...paver thickness. Not crushing but still has some weight to it. Is the 254 ok for this.....or should I have used something for a large format?

Thanks again....will post some progress pics as they come.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.

Similar threads

- Replies

- 2

- Views

- 97

- Replies

- 25

- Views

- 907

- Replies

- 3

- Views

- 153

- Replies

- 6

- Views

- 249

- Replies

- 5

- Views

- 226