I'm in the process of building my new pool and the equipment I've selected is the following:

1. Hayward Omni PL

2. Hayward VS 700 (115v)

3. Hayward H250FDP Gas (115v)

4. Hayward W3AQR15

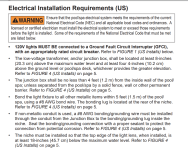

My question is how many amps should I be running from a dedicated circuit from the main panel to the automation subpanel? I already have a dedicated 20 amp that I can use for outlets. Is a 50 amp enough? I figured 15 for the pump, 15 for the heater, 15 for the saltwater generator.

What have others done with this setup?

1. Hayward Omni PL

2. Hayward VS 700 (115v)

3. Hayward H250FDP Gas (115v)

4. Hayward W3AQR15

My question is how many amps should I be running from a dedicated circuit from the main panel to the automation subpanel? I already have a dedicated 20 amp that I can use for outlets. Is a 50 amp enough? I figured 15 for the pump, 15 for the heater, 15 for the saltwater generator.

What have others done with this setup?