Eco-Lyme Nu-Calgon

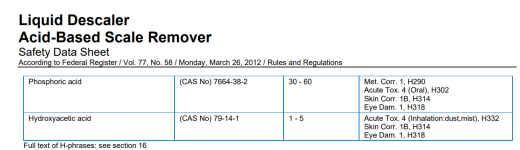

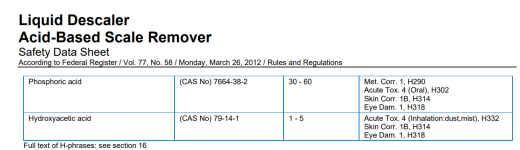

Liquid Descaler Acid-Based Scale Remover | STERIS

Find information for Liquid Descaler Acid-Based Scale Remover. View product specifications for this surgical instrument cleaning chemistry, or request a quote.

I was planning on doing this after I closed the pool for the season and had everything drained. I was going to run fresh water through it to flush out the descaling solution, but hen leave it dry until spring. Would that be OK, or should I wait until I open in the spring?Hydrochloric acid can be used, but use a very dilute solution.

Hydrochloric acid does not oxidize copper, but it does strip off the protective patina layer, which makes the copper susceptible to oxidation until the copper patina reforms.

All descalers will probably dissolve the protective patina layer, so you need to be extra careful with the chemistry after descaling.

Keep the pH up and keep the FC as low as possible without risking algae.

It might take about 2 weeks to reform a patina on the copper.

So i have been battling a positive CSI all summer. I have high TA fill water and surprisingly stubborn PH that does not want to rise despite aeration. This makes controlling my CSI difficult and I did not have great success this summer. My SWG showed some signs of scale, so I wanted to descale my heater as well, more as a preventive measure. I also get some popping/rattling sometimes when we fire it up.How did you determine that the heater was scaled?

It’s straight thread and there’s an o-ring inside like a compression fitting.If you unscrew the connector tubes, I would want to have two new U9-226 O-Rings (Part #13) to replace the old O-rings if necessary.

I am not 100% that the thread is 2" NPT, so verify as needed.

Will these work?It’s straight thread and there’s an o-ring inside like a compression fitting.

I’ve cracked 2 headers trying to get an NPT nipple to thread into it without leaking…it just goes to show you I was dumb enough to try twice

Those are NPT so I doubt it. The edge of the header inlet/outlet is very thin and sharp so I don’t think that O-ring would seal against it without popping off or getting cut…But I’d like to tryWill these work?

It looks like the actual Pentair unions will probably be my best bet. I was just hoping to avoid the proprietary fittings and paying the 'Pentair Tax'. But that's what it costs to play sometimes.The unions are not too expensive and probably better and easier than unscrewing the connector tubes.

https://www.amazon.com/Pentair-PKG188-Half-Union-Slip/dp/B006H43EG0

https://www.tcpoolequipment.com/poo...r-MasterTemp-400-Union-Kit-PKG-188-p10395.htm

https://www.amazon.com/Pentair-PKG188-Union-Adapter-Sta-Rite/dp/B004VTGKAU

He gets “Special Consideration” for warranty claims.I see you’re defending BigPool now…what are they paying you and how deep does the corruption go????

Mercedes are crud cars ... I only buy American ... Go Toyota!!!Product placement is so crass.

You gotta have some class.

By the way, here are some great products everyone should buy.

View attachment 536257

View attachment 536258View attachment 536259