- Mar 28, 2011

- 121

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Hello everyone, its been awhile but I'm finally about to start dig/rebar next week so I needed to finalize my spa jet plans. I need some help brainstorming this one!

In regards to powering my spa jets-- my original plan was to use four JetArray Inline spa jets which require 20 gpm each. I thought I could reach this pretty well with my single pump plumbing set up (original plan).

The JetArray Inlines have been on backorder for three months, and I've already pushed my build out once because I wanted to try to wait for them, I don't think I want to push it out again, since my subcontractor quotes are increasing by the month (as the economy is weird right now). I did find JetArray Clusters in stock somewhere, so I am thinking about using two JetArray Clusters (70gpm each!), and two to four "standard" spa jets. I want at least two seats to have a really fantastic spa experience, hence the crazy jets.

I'm pretty sure that I'll need to add some kind of jet pump to achieve that. So I'd like to ask for a spa jet pump recommendation and what the ideal plumbing set up for this system will be.

This is a new pool and spillover spa build. Pool/spa heat will be heat pump only. The pool will have no main drains, the only pool water suction will be the skimmer. The spa will have a 32" channel drain that supports three 2.5" plumbing connections. I do not plan to use an air blower, but I will have a large 3" air intake pipe. All plumbing to and from the spa will be 3", and the spa is roughly 20-25 feet from the equipment pad.

I'm not sure if I should have a standalone loop for the two JetArray Clusters, (still not sure I'd be able to achieve 140gpm with one pump on that) or if I should do more of a "booster" setup with both pumps and a loop with all of the jets. Or have a separate loop for the "standard" jets and a separate loop for the Clusters? What's the best way to accomplish this?

What's the best way to accomplish this?

JetArray Cluster:

This is the cartridge filter I have, however I haven't been able to find head loss information for it. In their specs they claim the "maximum pressure drop" is 2.9 psi and state a max flow rate of 134gpm.

www.circupool.com

www.circupool.com

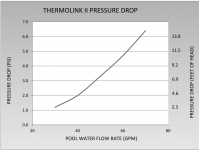

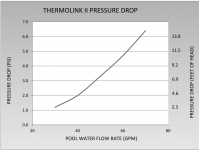

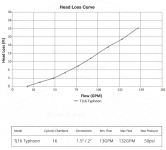

This cyclonic pre-filter came with my equipment kit, and I plan to use it, but am wondering if I should install a check valve bypass around it for spa mode? As the head loss increases quite a bit at high flow.

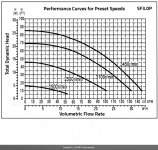

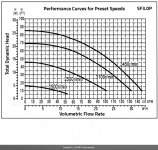

CircuPool SmartFlo 3hp variable speed pump (already purchased this for main pool/spa pump):

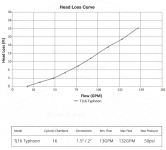

Head loss curve for the AquaCal heat pump I plan to use. This will have an external bypass plumbed. I believe the AquaCal external bypass kit has a ~5psi check valve:

In regards to powering my spa jets-- my original plan was to use four JetArray Inline spa jets which require 20 gpm each. I thought I could reach this pretty well with my single pump plumbing set up (original plan).

The JetArray Inlines have been on backorder for three months, and I've already pushed my build out once because I wanted to try to wait for them, I don't think I want to push it out again, since my subcontractor quotes are increasing by the month (as the economy is weird right now). I did find JetArray Clusters in stock somewhere, so I am thinking about using two JetArray Clusters (70gpm each!), and two to four "standard" spa jets. I want at least two seats to have a really fantastic spa experience, hence the crazy jets.

I'm pretty sure that I'll need to add some kind of jet pump to achieve that. So I'd like to ask for a spa jet pump recommendation and what the ideal plumbing set up for this system will be.

This is a new pool and spillover spa build. Pool/spa heat will be heat pump only. The pool will have no main drains, the only pool water suction will be the skimmer. The spa will have a 32" channel drain that supports three 2.5" plumbing connections. I do not plan to use an air blower, but I will have a large 3" air intake pipe. All plumbing to and from the spa will be 3", and the spa is roughly 20-25 feet from the equipment pad.

I'm not sure if I should have a standalone loop for the two JetArray Clusters, (still not sure I'd be able to achieve 140gpm with one pump on that) or if I should do more of a "booster" setup with both pumps and a loop with all of the jets. Or have a separate loop for the "standard" jets and a separate loop for the Clusters?

What's the best way to accomplish this?

What's the best way to accomplish this?JetArray Cluster:

This is the cartridge filter I have, however I haven't been able to find head loss information for it. In their specs they claim the "maximum pressure drop" is 2.9 psi and state a max flow rate of 134gpm.

CJ-2750 Cartridge Filter-CJ2750-2101-5A

This cyclonic pre-filter came with my equipment kit, and I plan to use it, but am wondering if I should install a check valve bypass around it for spa mode? As the head loss increases quite a bit at high flow.

CircuPool SmartFlo 3hp variable speed pump (already purchased this for main pool/spa pump):

Head loss curve for the AquaCal heat pump I plan to use. This will have an external bypass plumbed. I believe the AquaCal external bypass kit has a ~5psi check valve: