Update

It might be an issue depending on the amount of flow required by the feature.

Do you have a picture of the pool?

How much flow does the feature require?

You can go to a variable speed pump if you want or maybe try the smaller impeller to see if the feature still works.

If the pressure problem started only recently, then I would suspect a configuration problem or a defective piece of equipment.

Since your system is more complicated than a regular residential system, you will probably need an onsite visit so that a qualified technician can carefully go over everything to see what the actual problem is.

Maybe a valve is set incorrectly or maybe a failed check valve or maybe something else.

A very busy week carrying out the operations recommended by JamesW and replacing some spare parts.

1st step: THE PUMP: The brand’s engineer told me that the current 3HP pump is barely sufficient for the volume of water to be treated, the entire pool having to be renewed once, according to him. every 4 or 6 hours. For him : Pool volume (200 cubic meters) / 3HP pump flow (36 cubic meters per hour) = about 6 hours, so just normal. When converted to gallons, this gives pool volume (53,000 gallons) / pump flow (9,510 gallons / hour, or 158 GPM). So he told me the pump was properly sized.

Anyway, I forgot that I had exactly the same pump model but an 1HP one for a jaccuzzi which is totally separate from the pool. So it was easy to switch the pumps and see what happens with a 1HP pump connected to the pool system.

Result: absolutely no change. With a 1HP pump the pressure is as high as with a 3HP pump !

2nd step: replacing the filtrer lid which had exploded as well as spare parts to kiw the lid and the gasket as JamesW tough they seemed damaged. I emptied all the sand from the filter since it was not possible to change the gasket (under screws). Before restarting (I was already with the 1HP pump and had not restarted the 3HP pump) I decided not to put the sand back in the filter for testing.

Result: absolutely no change. With the 1HP pump and the sand filter empty of sand the pressure is still very high (a little more besides but this is due to the change of pressure gauge which was delivered with the new lid).

3rd step: full return to service. I put the sand back in the filter, ran the 1HP pump.

Result : absolutely no change, the pressure is exactly the same with and without sand (or a really tiny difference).

So I restarted the 3HP pump and it didn't really change anything .

So now, the system has been examined in almost all its elements and these tests show no defect to explain the high pressure.

After explaining to the brand’s engineer again :

. that the filter did not seem to be the cause since (in addition to having been completely dismantled and checked), in RECIRCULATE mode (where water does not circulate in the filter - I even carried out the test while the filter was completely disconnected from MPV) the pressure was also high

. that the MPV was new and appeared to operate normally after being disassembled and checked

. that the RETURN line did not seem to be the cause since in RINSE mode (where water circulates in the filter but does not go into the RETURN line since I can close the line valve without problem) the pressure is also high,

He wanted to test the filtration mode by discharging the water elsewhere than in the RETURN line. For me this is equivalent to the RINSE mode but anyway I did, by flooding the technical room for a few moments : it did not change the high pressure.

He is going to have the matter studied by another engineer, but between us I have little hope.

Some additional information: by changing the pump and therefore interested in the operation of the jaccuzzi which is quite similar to the swimming pool, I see that the jaccuzzi pump is located 4 meters below the water (compared to 7 meters for the swimming pool). When I stop the jaccuzzi pump, the gauge drops to 0. A few weeks ago when I had no high pressure problem on the swimming pool system, it was the same for the swimming pool: pump stopped the gauge was at 0. Now the pressure with the pump off is 5 to 7 PSI.

Another very surprising thing about the swimming pool for the pressure observed at the MPV (and not at the filter): pump stopped, pressure at 5PSI. I close all the inlet valves, put the MPV in the closed position. Due to the handling of the MPV which releases the pressure to the sewer, the pressure drops to 0. But a few hours later, the pressure rose to 5PSI. I relieve the pressure by letting the water escape from the MPV through a purge until the pressure is at 0. A few hours later, the pressure 5PSI is back up. As my whole system was dismantled, I took the opportunity to examine where this pressure could come from by gradually dismantling all the piping elements and valves connected to the MPV. To see that water was flowing from the pump to the MPV. All the inlet valves to the pump being properly closed (very serious verification made no leaks), the pressure is created in my opinion by the water or the air present between the 3 valves coming from VACUUM, TANK and MAIN DRAIN and the pump outlet. However, the problem can hardly come from the pump since when I switched the pumps between 1HP and 3HP, there was always overpressure.

Maybe a minor detail, but since I have this high pressure problem, the pump lid gasket is frequently damaged (it slackens). Likewise, I can no longer fully close the lid (to get the marks perpendicular to the pump as indicated in the manual and as it works very well on the jaccuzzi pump). The lid seems tightly closed but something has happened, I don't know what. I bought a new cover and new gasket that I tried: I can't close it perpendicular anymore.

Stefany, maybe a silly question but ....... those two gray valves that are used before and after the salt generator, are they always on that position? I know the red handles everywhere are currently closed because your filter is broke, but those grey valves are partially closed as well. That would increase your filter pressure.

TEXAS SPLASH when you said the problem was probably right after the filter: The problem still exists when I disconnect the RETURN line and connect a temporary pipe to see what the filtration pressure is when the water is drained from the filter.

Can we agree that the problem cannot come:

. the water inlet: the high pressure exists regardless of the source of the water (VACUUM, MAIN DRAIN, TANK)

. filter: Since I tried without the sand, by disconnecting the filter from the MPV and there is still an overpressure (noted on the MPV since by definition there is no longer a gauge connected to the circuit since the filter is disconnected)

. of the RETURN line since when I disconnect this line the high pressure is still thre (RINSE position or even direct discharge after the filter without piping)

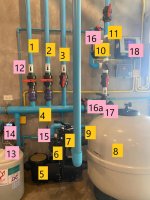

I know this is difficult to understand, but I am wondering if it is possible that the high pressure is being caused before the filter. That is to say on one of the following 5 elements I tried to describe with pictures attached :

1) pipeline which centralizes the 3 water inlets,

2) pump,

3) check valve just after the pump,

4) pipe connecting the pump valve to the MPV,

5) MPV.

Knowing that the pump has been checked and that even with a 1HP pump the overpressure exists and that the MPV is new ... What do you think? You are my only hope because I really have no idea how to find a solution.

Merci beaucoup !