- Feb 12, 2021

- 69

- Pool Size

- 18000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

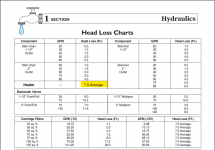

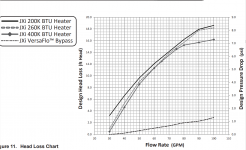

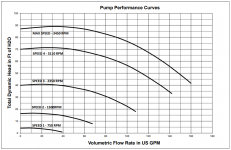

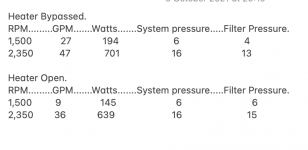

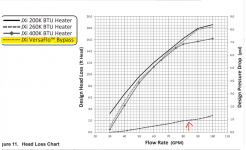

Hi guys. After finishing my pool I had the heater bypass valve closed for the 30 recommended days (quartz pool). Rpm and gpm numbers were in the expected range at that point. Now that I opened the bypass valve in the heater (and everything else being equal than before) I'm noticing a very sharp drop in gpm throughout the curve. So much so that in order to get the minimum 24 gpm my Intellichlor requires I need to ramp up my pump to 2000 rpm (before I would achieve that gpm with 1500 rpm). I've attached a graph with my curves. Light blue line is gpm before opening the heater and the dark blue line is after. Are these numbers ok? I seem weird to me to have this massive head loss only from going through the heater coil.

Any help and/or bumps will be appreciated.

Thanks!

MZ

Any help and/or bumps will be appreciated.

Thanks!

MZ