So as I near completion of my renovation the equipment has finally come in and been set, with the plumbing completed. We have two pumps, one is the filter/heater/SWCG, the other runs the in floor (which was already there prior to the reno and I was talked into updating/expanding it) and alternatively the bubblers or deck jets. Currently, as plumbed, the filter pump gets suction from the main drain and one skimmer, while the other skimmer supplies the in floor/feature pump. I also have a debris canister attached to the main pump system. I am not sure this setup makes sense to me.

The explanation I have received so far, which I am not sure about, is that I "want my main drain on the filter pump because it turns over so much more water that you want getting filtered." Fair point on having the debris catching main drain end up in a filter I guess, but the big stuff should be caught by the canister, and the small stuff I would think would get mostly blown into circulation and eventually hoovered by a skimmer. It seems to me that the current setup means I am going to have to run both pumps when I am in floor cleaning, in order to have the main drain sucking while the infloors are working. And when I am skimming in this setup, only one skimmer is doing anything, unless I run the cleaner as well (at a lower skimming speed). I feel like this was probably a goof and they're just trying to excuse doing it this way, but maybe there is something I am missing here.

I would think you would want the main drain as the suction for the infloor/features, with the two skimmers on the filter pump. That way, you could either run the infloor, ideally sucking up all the big debris getting blown towards the drain and into the canister. The rest of the time, this system could be off, or running features as needed. Meanwhile, the main pump would run both skimmers/SWCG as needed, on an entirely separate schedule, and would not need a debris canister, because that's what the skimmer basket is for.

They also did not plumb in a heater bypass like I asked. I am not sure how hard it will be to redo at this point, it looks like I may have to sacrifice the current check valve in order to make a bypass work. I don't even think I need the check valve after the heater before the SWCG based on what I've read here, but all the pool people seem to think it's very important, even when I point out that I don't have an in line. I wouldn't expect whatever small amount of chlorine that is generated just before the pump shuts off to go backwards and cause a considerable buildup in the heater, but they seem to be very concerned about that. Opinions on how best to redo with a bypass would be appreciated, I may try to tackle it myself.

Sadly the guy forgot the check valve on the spa line of the infloor system, so my spa is equalizing every time the pump is off, should be fun for him to dig up and fix.

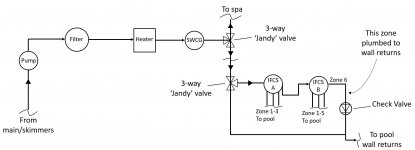

Pics attached of the current setup. Top tier paint skills included.

The explanation I have received so far, which I am not sure about, is that I "want my main drain on the filter pump because it turns over so much more water that you want getting filtered." Fair point on having the debris catching main drain end up in a filter I guess, but the big stuff should be caught by the canister, and the small stuff I would think would get mostly blown into circulation and eventually hoovered by a skimmer. It seems to me that the current setup means I am going to have to run both pumps when I am in floor cleaning, in order to have the main drain sucking while the infloors are working. And when I am skimming in this setup, only one skimmer is doing anything, unless I run the cleaner as well (at a lower skimming speed). I feel like this was probably a goof and they're just trying to excuse doing it this way, but maybe there is something I am missing here.

I would think you would want the main drain as the suction for the infloor/features, with the two skimmers on the filter pump. That way, you could either run the infloor, ideally sucking up all the big debris getting blown towards the drain and into the canister. The rest of the time, this system could be off, or running features as needed. Meanwhile, the main pump would run both skimmers/SWCG as needed, on an entirely separate schedule, and would not need a debris canister, because that's what the skimmer basket is for.

They also did not plumb in a heater bypass like I asked. I am not sure how hard it will be to redo at this point, it looks like I may have to sacrifice the current check valve in order to make a bypass work. I don't even think I need the check valve after the heater before the SWCG based on what I've read here, but all the pool people seem to think it's very important, even when I point out that I don't have an in line. I wouldn't expect whatever small amount of chlorine that is generated just before the pump shuts off to go backwards and cause a considerable buildup in the heater, but they seem to be very concerned about that. Opinions on how best to redo with a bypass would be appreciated, I may try to tackle it myself.

Sadly the guy forgot the check valve on the spa line of the infloor system, so my spa is equalizing every time the pump is off, should be fun for him to dig up and fix.

Pics attached of the current setup. Top tier paint skills included.