A note about meter and pipe sizing.

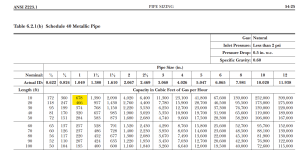

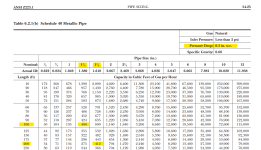

Meters and pipes are sized for a specific volume flow at a specific pressure drop.

The more flow you put through a meter or a line, the more the pressure drops.

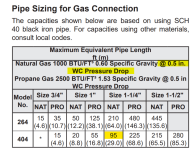

The typical pressure is 0.25 psi, which is 6.9” w.c.

The maximum “Low Pressure” is 0.5 psi (8 ounces per square inch), which is 13.8” w.c.

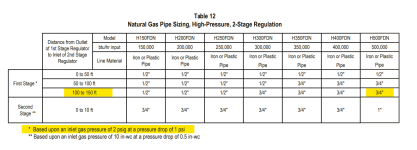

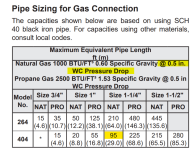

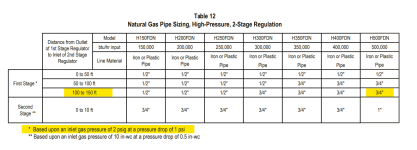

There is also 2 psi "High Pressure" available from some utilities and that has its own design requirements.

For example, a 3/4” line at 2 psi can supply 500,000 btu/hr at 150 feet long at a pressure drop of 1 psi.

1 psi is 27.68” w.c, so you still have 27.68” w.c at the regulator near the heater for 2 psi (high pressure).

It looks like the OP's utility does not offer 2 psi service, but they can check if they think that that would be helpful.

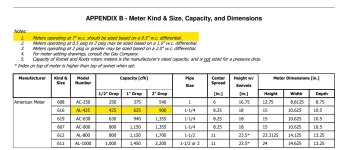

For the AL-425 meter, there are three different ratings based on the allowable pressure drop.

425 CFH at a 0.5” w.c drop.

583 CFH at a 1” w.c pressure drop.

898 CFH at a 2” w.c pressure drop.

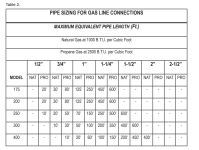

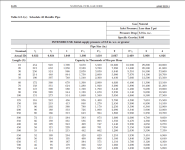

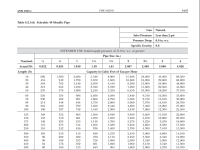

For 1.25” line, the pressure drop is about 5.00 milliinches per foot of pipe for a flow of 400 CFH.

So, the length of line that is acceptable depends on the allowable pressure drop.

If you allow a 500 milliinch drop (0.5” w.c), then the length is limited to 100 feet.

If the line is 150 feet, then the pressure drop is about 0.75" w.c, which is not too bad.

So, the 1.25" line would probably be fine and the pressure would not drop too low.

You could increase the pressure to 8" w.c and use 1.25" line for the entire run and it would probably give plenty of pressure without getting anywhere near the lower limit.

However, you don't want to go outside of the Installation manual unless you have an engineer approve of the plans.

If you allow a 1,000 milliinch drop (1” w.c) then the length can be up to 200 feet.

So, you need to know the minimum and maximum pressure requirements for all appliances that will be on the line.

You can’t set the pressure higher than the maximum on any appliance.

You can’t allow a total pressure drop that will result in the pressure at any appliance being less than the minimum.

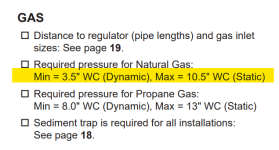

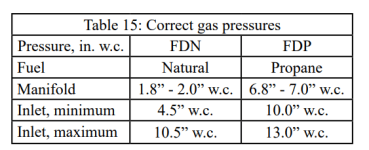

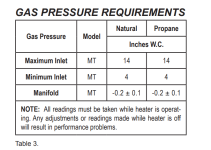

For example the Avia 404 shows a range of 3.5 to 10.5” w.c.

If the pressure starts at 7” w.c, which is typical, you can allow up to 3.5” of total pressure drop across the meter and the line.

The total load is 66 + 75 + 400 = 541 cubic feet per hour.

So, the meter will have a 1” w.c drop at full flow.

This allows the 1.25” line to have up to 2.5” of drop (2,500 milliinch), which is 500 feet.

However, you never want to hit the limits of the range and you want to be at least 1” below the maximum and at least 1” above the minimum.

If you allow 1.5” w.c pressure drop, for the line, then that is 300 feet.

Most design guidelines use a 0.500” w.c (500 milliinches) pressure drop so that there is a lot of margin for error.

Once you go above 0.5” w.c drop, you have to be very careful about the design because you risk creating a situation where the pressure at the appliances is too low at full load.

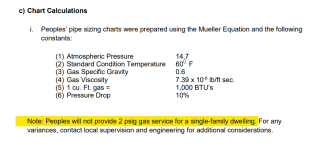

The charts in the installation books use 0.5” w.c because they know that virtually no one is going to do the full engineering calculations.

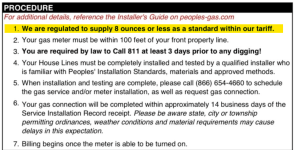

Unless you have a Licensed Qualified Engineer do the design, you need to follow all installation guidelines.

If a manufacturer sees that the installation does not meet the book requirements, they will assume that the pressure was insufficient unless you can prove that the pressure was always good and you would need design plans stamped by a Licensed Engineer.

You also have to consider the minimum and maximum pressure requirements of all appliances.

You have to know the lowest high pressure and the highest low pressure.

For a meter, I think that allowing up to 1” is probably acceptable.

I think that 2” is probably excessive.

For lines that go to the heater, follow the manufacturer’s requirements unless you have plans stamped by an engineer.

In any case, it is always recommended that the heater be fully “Commissioned” after installation to ensure that it is functioning properly in all regards.

This serves as the official “Installation” date and it establishes the basic initial benchmarks at the beginning to prove that everything was installed correctly.

If there is a problem later, the initial readings can be compared to the newest readings for comparison.

Meters and pipes are sized for a specific volume flow at a specific pressure drop.

The more flow you put through a meter or a line, the more the pressure drops.

The typical pressure is 0.25 psi, which is 6.9” w.c.

The maximum “Low Pressure” is 0.5 psi (8 ounces per square inch), which is 13.8” w.c.

There is also 2 psi "High Pressure" available from some utilities and that has its own design requirements.

For example, a 3/4” line at 2 psi can supply 500,000 btu/hr at 150 feet long at a pressure drop of 1 psi.

1 psi is 27.68” w.c, so you still have 27.68” w.c at the regulator near the heater for 2 psi (high pressure).

It looks like the OP's utility does not offer 2 psi service, but they can check if they think that that would be helpful.

For the AL-425 meter, there are three different ratings based on the allowable pressure drop.

425 CFH at a 0.5” w.c drop.

583 CFH at a 1” w.c pressure drop.

898 CFH at a 2” w.c pressure drop.

For 1.25” line, the pressure drop is about 5.00 milliinches per foot of pipe for a flow of 400 CFH.

So, the length of line that is acceptable depends on the allowable pressure drop.

If you allow a 500 milliinch drop (0.5” w.c), then the length is limited to 100 feet.

If the line is 150 feet, then the pressure drop is about 0.75" w.c, which is not too bad.

So, the 1.25" line would probably be fine and the pressure would not drop too low.

You could increase the pressure to 8" w.c and use 1.25" line for the entire run and it would probably give plenty of pressure without getting anywhere near the lower limit.

However, you don't want to go outside of the Installation manual unless you have an engineer approve of the plans.

If you allow a 1,000 milliinch drop (1” w.c) then the length can be up to 200 feet.

So, you need to know the minimum and maximum pressure requirements for all appliances that will be on the line.

You can’t set the pressure higher than the maximum on any appliance.

You can’t allow a total pressure drop that will result in the pressure at any appliance being less than the minimum.

For example the Avia 404 shows a range of 3.5 to 10.5” w.c.

If the pressure starts at 7” w.c, which is typical, you can allow up to 3.5” of total pressure drop across the meter and the line.

The total load is 66 + 75 + 400 = 541 cubic feet per hour.

So, the meter will have a 1” w.c drop at full flow.

This allows the 1.25” line to have up to 2.5” of drop (2,500 milliinch), which is 500 feet.

However, you never want to hit the limits of the range and you want to be at least 1” below the maximum and at least 1” above the minimum.

If you allow 1.5” w.c pressure drop, for the line, then that is 300 feet.

Most design guidelines use a 0.500” w.c (500 milliinches) pressure drop so that there is a lot of margin for error.

Once you go above 0.5” w.c drop, you have to be very careful about the design because you risk creating a situation where the pressure at the appliances is too low at full load.

The charts in the installation books use 0.5” w.c because they know that virtually no one is going to do the full engineering calculations.

Unless you have a Licensed Qualified Engineer do the design, you need to follow all installation guidelines.

If a manufacturer sees that the installation does not meet the book requirements, they will assume that the pressure was insufficient unless you can prove that the pressure was always good and you would need design plans stamped by a Licensed Engineer.

You also have to consider the minimum and maximum pressure requirements of all appliances.

You have to know the lowest high pressure and the highest low pressure.

For a meter, I think that allowing up to 1” is probably acceptable.

I think that 2” is probably excessive.

For lines that go to the heater, follow the manufacturer’s requirements unless you have plans stamped by an engineer.

In any case, it is always recommended that the heater be fully “Commissioned” after installation to ensure that it is functioning properly in all regards.

This serves as the official “Installation” date and it establishes the basic initial benchmarks at the beginning to prove that everything was installed correctly.

If there is a problem later, the initial readings can be compared to the newest readings for comparison.

Last edited: