In the process of selecting a pool builder, and one of the pool builders mentioned that they use high psi gunite (4,000 psi IIRC). They stated that the other builders in the area only used 2,500 psi. We're on expansive clay soil. Is this something to be concerned about or just fluff?

Gunite PSI

- Thread starter cybertoad

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jul 21, 2013

- 65,396

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I think proper gunite or shotcrete techiques and discarding all rebound are more important then PSI differences.

I would be more impressed by a PB discussing the training and techniques of his crew then the PSI of equipment. Good equipment will not fix poor applications. A good craftsman can do great work with poor equipment.

I would be more impressed by a PB discussing the training and techniques of his crew then the PSI of equipment. Good equipment will not fix poor applications. A good craftsman can do great work with poor equipment.

For what it’s worth, I think almost all pool builders in Central California subcontract everything out to the same small handful of trade subs. Kind of a Crud shoot and makes due diligence difficult.

- Jul 21, 2013

- 65,396

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

For what it’s worth, I think almost all pool builders in Central California subcontract everything out to the same small handful of trade subs. Kind of a Crud shoot and makes due diligence difficult.

That's the way it is in most areas. A PB cant do enough volume to keep specialized crews busy. Easier to subcontract gunite, plaster, tile, electrical, plumbing as needed to crews who stay busy moving between different PBs jobs. The good PBs know who the good crews are to use.

*Edit b/c I was responding to wrong quoteIn the process of selecting a pool builder, and one of the pool builders mentioned that they use high psi gunite (4,000 psi IIRC). They stated that the other builders in the area only used 2,500 psi. We're on expansive clay soil. Is this something to be concerned about or just fluff?

We also have expansive and I have been asking every PB how they deal with it.

The answer that made me comfortable was raising the level of engineering for the design. The PBs who are familiar with my area said they design using the super-expansive standard. When I looked into what that actually meant it relates to min. thickness for the shell as well as specific placement and size of rebar to provide structural integrity.

When it comes to the decking there are techniques they need to use as well to compensate for expected movement

-think carefully before doing cantilever poured deck

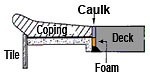

-extra care to expansion and mastic separating the coping from deck

Last edited:

4000 minimum wet or dry shoot.

3.5” MINIMUM steel embedment both sides.

If an Asa certified nozzleman is available, pay the outfits premium - it’s worth it..

I laugh at the shoot vids & pics I see here or on YouTube.. actually, I cringe I don’t actually laugh.

3.5” MINIMUM steel embedment both sides.

If an Asa certified nozzleman is available, pay the outfits premium - it’s worth it..

I laugh at the shoot vids & pics I see here or on YouTube.. actually, I cringe I don’t actually laugh.

Thanks for the info guys. Does anyone know if there is any documentation about the super-expansive standard available? I want to make sure to specify this all in the contract.

I would suggest that you get an engineer to provide the specifications for your build.

I think on the decking, I'll have them pour the deck directly to the edge of the pool, instead of using separate coping/edging. That way, if there is any lifting of the soil, it will leave a gap between the top of the pool tile and the bottom of the deck, which will be much easier to deal with than an uneven surface between the coping and the deck.

- Jul 21, 2013

- 65,396

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

I think on the decking, I'll have them pour the deck directly to the edge of the pool, instead of using separate coping/edging. That way, if there is any lifting of the soil, it will leave a gap between the top of the pool tile and the bottom of the deck, which will be much easier to deal with than an uneven surface between the coping and the deck.

Pool structure needs to float independant of decking otherwise you get cracking as the two different bodies shift.

Gap between the top of the pool tile and the bottom of the deck will lead to erosion and other problems from overflows of water.

There should be an caulked expansion joint between coping and deck.

Thanks for the info guys. Does anyone know if there is any documentation about the super-expansive standard available? I want to make sure to specify this all in the contract.

Super expansive??

Not much content has been added..

which edition are you reading?

Thanks for the info guys. Does anyone know if there is any documentation about the super-expansive standard available? I want to make sure to specify this all in the contract.

You have the right to see your pool engineering docs. Ask for them.

Here is a quick pool engineering search result on the standards.

Rebar closer together and stronger overall structural requirements

Attachments

You might want to find out what your city code requirements are. This way during your PB review you know they are meeting all the requirements. For example my city requires either a soil test or engineer for expansive soil along with shotcrete minimum of 4500 psi ( high sulfate area).

NorCalX- The screen shot looks a lot like the engineer group I used out of Tustin California..

NorCalX- The screen shot looks a lot like the engineer group I used out of Tustin California..

i think thats where i found itYou might want to find out what your city code requirements are. This way during your PB review you know they are meeting all the requirements. For example my city requires either a soil test or engineer for expansive soil along with shotcrete minimum of 4500 psi ( high sulfate area).

NorCalX- The screen shot looks a lot like the engineer group I used out of Tustin California..

PoolEng website

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.