Need to get a pump tomorrow and going with a VS. I know the VS has to be hard wired, which today is on a timer with the salt system. I just just hard wire it all and figure out where the flow switch turns on and run the pump for 8 hrs a bit over that rpm? Then run below the rest of the time to get the benefits? Also some of that time needs to run the cleaner which I assume maybe 2 hrs should cover the pool? Any insight Thinking of just removing the pegs on the timer to avoid some wiring.

Going to VS from single. How do I setup SW system?

- Thread starter jhfla

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Assuming your pool is currently wired and working, the simplest way will be for you to hardwire the new VS pump to 240V (consult the pump's manual) and program the pump's electronic timer, so that it overlaps SWG and cleaner intervals at desired speeds. All other electrical connections will stay the same.Need to get a pump tomorrow and going with a VS. I know the VS has to be hard wired, which today is on a timer with the salt system. I just just hard wire it all and figure out where the flow switch turns on and run the pump for 8 hrs a bit over that rpm? Then run below the rest of the time to get the benefits? Also some of that time needs to run the cleaner which I assume maybe 2 hrs should cover the pool? Any insight Thinking of just removing the pegs on the timer to avoid some wiring.

ManiacalMama

Bronze Supporter

- Jul 18, 2017

- 244

- Pool Size

- 13500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-30 Plus

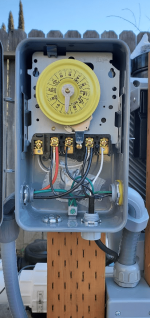

Not sure which timer you have. I wired an Intermatic T104R with a VSP and SWG.Need to get a pump tomorrow and going with a VS. I know the VS has to be hard wired, which today is on a timer with the salt system. I just just hard wire it all and figure out where the flow switch turns on and run the pump for 8 hrs a bit over that rpm? Then run below the rest of the time to get the benefits? Also some of that time needs to run the cleaner which I assume maybe 2 hrs should cover the pool? Any insight Thinking of just removing the pegs on the timer to avoid some wiring.

My VSP is set as "always on" by wiring it to the line terminals. I use the pump's onboard scheduling to operate it.

I then wired the SWG to the load terminals so that I can control it via the timer clock and to come on within a certain window.

It was pretty straight forward as long as you know which terminals are which.

I have the same timer i just removed the on off tabs and hooked it up so both the pump and sw direct feed using the flow meter for the sw. Is this ok to do?Not sure which timer you have. I wired an Intermatic T104R with a VSP and SWG.

My VSP is set as "always on" by wiring it to the line terminals. I use the pump's onboard scheduling to operate it.

I then wired the SWG to the load terminals so that I can control it via the timer clock and to come on within a certain window.

It was pretty straight forward as long as you know which terminals are which.

View attachment 456433

- Apr 10, 2018

- 6,501

- Pool Size

- 18375

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Nope. The SWG flow switch should not be relied on as the primary and sole safety device. If it fails with the pump off, a build-up of gas in the cell can result in an explosion.I have the same timer i just removed the on off tabs and hooked it up so both the pump and sw direct feed using the flow meter for the sw. Is this ok to do?

Connect the pump to the line in terminals (1 and 3). These are always hot. Connect the SWG to the load side terminals (2 and 4). Schedule the SWG to run within the pump schedule times.

ManiacalMama

Bronze Supporter

- Jul 18, 2017

- 244

- Pool Size

- 13500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-30 Plus

I wired mine the exact way Rancho described, for the exact reason.I have the same timer i just removed the on off tabs and hooked it up so both the pump and sw direct feed using the flow meter for the sw. Is this ok to do?

The flow switch is a backup switch, not the main switch.

It's a really easy swap of wires. Just make sure you cut the power at the breaker if you do it.

Below my timer I also have a "fireman's switch" to cut power to all of it.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.