W,

If this were my pool, and I was as sharp as you are with Raspberry pi stuff, I would build a simple relay circuit that does what you want to do.. Basically, when off it would allow the EasyTouch to control the valves.. When the relays were energized, it would open the Intake and Return valve connections to the EasyTouch, and allow you to turn the valves the way you want with an external input.. The EasyTouch controls the normal operation, but your R-pi does the daily water exchange...

You would not even need the R-pi as you could just use a couple of DPDT relays and turn them on or off with the ET's scheduling..

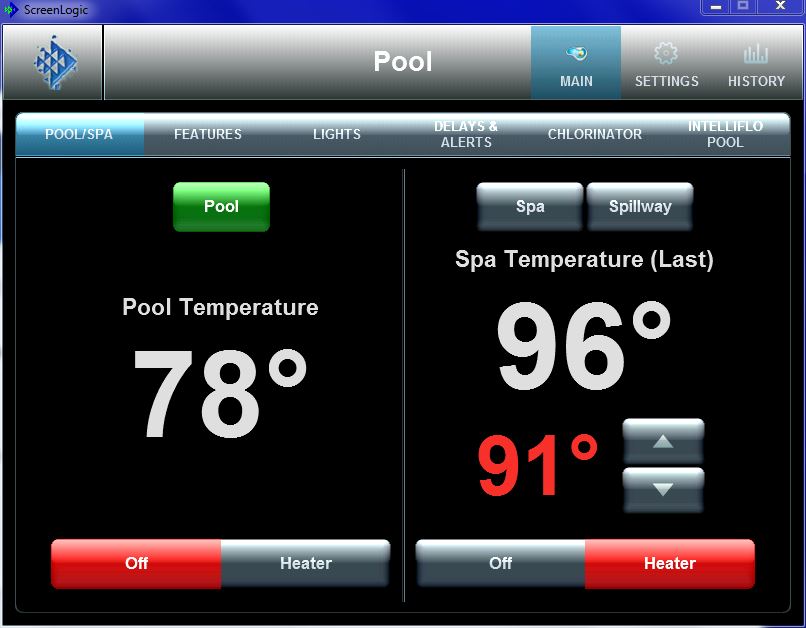

This would also make it so that anytime you went into the Spa mode, the pump speed would be correct, and the heater would come one all at one time.

I am surprised there is not at least a pipe between the spa and the pool..

I now understand your frustration with the ET...

Thanks for your patience..

Jim R.