Building a DIY spillover pool in haste and hoping to minimize errors...

Starting new tread with overview and request for general guidance.

Project:

Cast Concrete spillover pool on cliff edge. (not gunite/shotcrete)

Offgrid solar electricity, no permitting, no one to save me from myself, etc (Ranch Property)

~900sqft, ~29,000g

~59ft spillover weir

~51" pool depth

Pump/Basin room 4ft from Pool wall - Very short plumbing runs

Basin Floor is 12ft below top of pool water (6ft difference in typical basin to pool water level)

Perimeter trough collection gravity flows into adjoining basin (no drains in trough)

No skimmers (intend to push water over weir)

Not looking for robust waterfall over weir, but cleaning benefit

- Pump 1 Suction: direct from Basin (returns to pool via 4" manifold for pushing spillover - Wall Jet count TBD - perhaps 8-10?)

- Pump 2 Suction: wall suction ports (returns to pool via 4" manifold for filtration, heat pump in line)

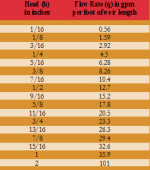

- Plumbing manifolds: 4" primary trunk lines to/from pump room feeding 2" stub outs though pool wall (1.5" jets)

Concerns:

- Weir elevation compared to pool deck elevation. Is <1" below coping viable? Looking for zero-edge style, but not installing gutters on all 4 sides.

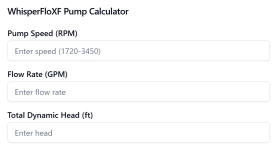

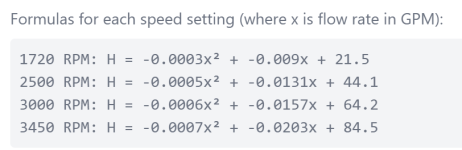

- Is one powerful pump sufficient for spillover of this size (4" trunk line, very short runs from pump).

- Is one 2nd pump for conventional recirculation and Heat Pump sufficient?

- Connect each pump to their own filter?

thank you for any guidance! This is certainly a ready, fire, aim DIY project....

Starting new tread with overview and request for general guidance.

Project:

Cast Concrete spillover pool on cliff edge. (not gunite/shotcrete)

Offgrid solar electricity, no permitting, no one to save me from myself, etc (Ranch Property)

~900sqft, ~29,000g

~59ft spillover weir

~51" pool depth

Pump/Basin room 4ft from Pool wall - Very short plumbing runs

Basin Floor is 12ft below top of pool water (6ft difference in typical basin to pool water level)

Perimeter trough collection gravity flows into adjoining basin (no drains in trough)

No skimmers (intend to push water over weir)

Not looking for robust waterfall over weir, but cleaning benefit

- Pump 1 Suction: direct from Basin (returns to pool via 4" manifold for pushing spillover - Wall Jet count TBD - perhaps 8-10?)

- Pump 2 Suction: wall suction ports (returns to pool via 4" manifold for filtration, heat pump in line)

- Plumbing manifolds: 4" primary trunk lines to/from pump room feeding 2" stub outs though pool wall (1.5" jets)

Concerns:

- Weir elevation compared to pool deck elevation. Is <1" below coping viable? Looking for zero-edge style, but not installing gutters on all 4 sides.

- Is one powerful pump sufficient for spillover of this size (4" trunk line, very short runs from pump).

- Is one 2nd pump for conventional recirculation and Heat Pump sufficient?

- Connect each pump to their own filter?

thank you for any guidance! This is certainly a ready, fire, aim DIY project....

Last edited: