Bill1974

Well-known member

- Jun 18, 2014

- 675

- Pool Size

- 32000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

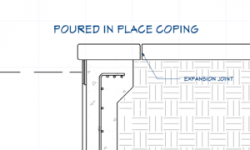

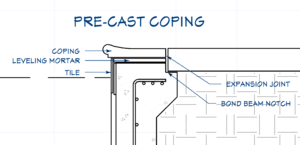

I am guessing when the decking was poured it attached in this area and with with the movement of the decking it's lifting the top corner of the pool and coping. The cracking in the skim coat is close to when the bottom of the deck pour is. The coping and the mortar used to attach it to the pool wall is stronger in tension than the concrete of the pool wall, it cracked at the weakest location. Fortunately it has not cracked though the wall. If it continues to be an issue cutting a relief between the deck pour and the pool wall should eliminate the issue and the coping and bond beam can be repaired for good. I don't think a regular rotary concrete saw will be able to cut that depth, you may need to find someone with the chainsaw type of concrete saw to cut deep enough to completely break the bond between the deck pour and pool. There should have been foam (or some other type of isolation barrier) on the pool wall before the deck was poured to create a slip joint. The ends of the rebar could have been bent and tied to the last row of rebar too.