- May 31, 2022

- 674

- Pool Size

- 8000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-20

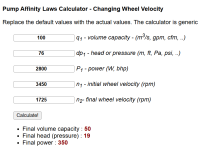

As the first step in this season's pool project -- saving money on electricity by reducing head loss in my plumbing -- I'm plotting curves on pump charts.

My 3HP IntelliPro VSF pump reports to the EasyTouch its speed, power consumption, and flow rate. But the imprecise flow gauge in my system doesn't agree with the pump's reported flow rate, and my meter's at work so I can't confirm that the reported power consumption is accurate.

Anyone know which of those three quantities are measured directly and therefore trustworthy, and which are derived or estimated from measurements of other quantities?

My 3HP IntelliPro VSF pump reports to the EasyTouch its speed, power consumption, and flow rate. But the imprecise flow gauge in my system doesn't agree with the pump's reported flow rate, and my meter's at work so I can't confirm that the reported power consumption is accurate.

Anyone know which of those three quantities are measured directly and therefore trustworthy, and which are derived or estimated from measurements of other quantities?