- Feb 6, 2015

- 7,932

- Pool Size

- 12300

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

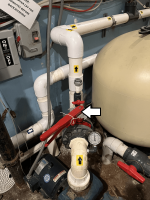

Based on if the filters are in parallel or in series may change the proper backwash procedure.Will post some pics along with proposed solutions.

Post those pics from a few different angles so we can see everything.