We have two filters on our outdoor pool. Is it best to backwash them separately or can both filters be put in backwash mode at the same time? If it is best to backwash them separately, should one filter be left in "Filter" mode, set to "Closed", or some other setting while the other filter is being backwashed?

Backwash procedure for pool with 2 filters

- Thread starter JPMorgan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are they in series? One will be in operational mode (Filter) and backwash the other.

ol_whistle_britches

Gold Supporter

Given the 60k size and the 5hp pump called out in your signature, I would expect them to be in parallel. I hope they’re in parallel.

If I’m reading this right, TR 140’s are rated for 106 - 141 GPM, with the higher spec for the TR-140C, which denotes commercial. Do you have the commercial or the residential model?

Your sta-rite pump is capable of exceeding that filter spec all the way up to ~80-115ft of dynamic head. Pump curve puts its max flow around 220 GPM at low head.

I see no reason not to leave one in service, while you backwash the other. That being said, as long as you have enough drain capacity to take the flow, I don’t see a mechanical reason why you can’t backwash them both at the same time to save time.

Closing one filter down (unless there’s a bypass) will divert too much flow into the other.

If I’m reading this right, TR 140’s are rated for 106 - 141 GPM, with the higher spec for the TR-140C, which denotes commercial. Do you have the commercial or the residential model?

Your sta-rite pump is capable of exceeding that filter spec all the way up to ~80-115ft of dynamic head. Pump curve puts its max flow around 220 GPM at low head.

I see no reason not to leave one in service, while you backwash the other. That being said, as long as you have enough drain capacity to take the flow, I don’t see a mechanical reason why you can’t backwash them both at the same time to save time.

Closing one filter down (unless there’s a bypass) will divert too much flow into the other.

So... leave one in filter mode while backwashing the other?Closing one filter down (unless there’s a bypass) will divert too much flow into the other.

Not sure what this means. Can you explain further? Are "in series" and "in parallel" different configurations. How would I know the difference?I would expect them to be in parallel. I hope they’re in parallel.

- Jun 24, 2021

- 17,057

- Pool Size

- 29000

- Surface

- Vinyl

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

In series:

pump --> Filter --> Filter -->

Parallel:

pump --> Filter --> Filter -->

Parallel:

----> Filter-->

|

Pump --|

-----> Filter -->

ol_whistle_britches

Gold Supporter

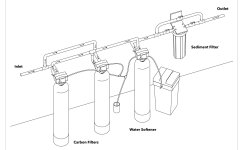

Sometimes a picture is worth a thousand words…Are "in series" and "in parallel" different configurations. How would I know the difference?

The 2 carbon filters are “parallel” to each other.

The filtration system taken as a whole is in series, consisting of carbon -> water softener -> sediment filter.

That’s how I would do it. Also, notice the bypass loop around the sediment filter, which allows it to be taken offline completely.So... leave one in filter mode while backwashing the other?

Another (unrelated) issue we are having is a flow rate that is not meeting state requirements. Flow rate is typically 120 gpm. 170 gpm is required. From comments above it sounds like our pump is very capable of delivering that amount of flow. Any idea what would be the most like cause or the first things to explore? If I sent photos of plumbing configuration would that help? We have three different proposals from a pool company to try to address this. Would it help if I sent those?

ol_whistle_britches

Gold Supporter

Or sometimes @PoolStored finds 9 words to describe it succinctly….Sometimes a picture is worth a thousand words

If I place both filters in "Recirculation" mode and the flow rate does not increase at all, then that should rule out any issue with the filters, right? One of the proposals included replacing the filters.

Either pictures or a drawing of your flow paths would help.If I place both filters in "Recirculation" mode and the flow rate does not increase at all, then that should rule out any issue with the filters, right? One of the proposals included replacing the filters.

At what point in the flow is the 170gpm required and/or measured? Before the filters? After the filters? At the return pipe to the pool?Another (unrelated) issue we are having is a flow rate that is not meeting state requirements. Flow rate is typically 120 gpm. 170 gpm is required. From comments above it sounds like our pump is very capable of delivering that amount of flow. Any idea what would be the most like cause or the first things to explore? If I sent photos of plumbing configuration would that help? We have three different proposals from a pool company to try to address this. Would it help if I sent those?

Are your filters capable of handling this 170gpm flow if this requirement is measured after the filters?

ol_whistle_britches

Gold Supporter

The flow rate is dependent on the system head (think resistance). It’s hard to say whether the current pump is capable or not without knowing the head. It can only do what 5hp can do. Part of the head is determined by static factors like difference in elevation, line diameter, quantity of things like skimmers and drains. Of course things that can change like mechanically like valve settings, plugged lines, dirty filters, etc all get considered too. I’ll let someone else give you more color on that topic, as my explanation in my head isn’t perfectly clear right now.Flow rate is typically 120 gpm. 170 gpm is required.

If you’re getting quotes for solutions from an honest company, I’m guessing they’ve eliminated the simple answers like valve positioning. Pictures wouldn’t hurt. Your vendor probably would appreciate it if you redacted any identifying info before you posted them.

Maybe. Maybe not. It’ll rule out the clogged filter theory. The TR-140 filter comes in residential and commercial models. The commercial models come in a 2” glued fitting and a 3” flanged fitting model. 3” PVC has a cross section that is 2.25 times the size of 2”, so if you have 3” running to 2 x 2” filters you have a restriction by default before you ever get “inside” the filter. Bypassing the filter (the recirculate position) at the multiport valve won’t eliminate that because the valve itself becomes the restriction.If I place both filters in "Recirculation" mode and the flow rate does not increase at all, then that should rule out any issue with the filters, right? One of the proposals included replacing the filters.

I believe the pump specs a 2.5” inlet on it, which means running 2” PVC (or even 2.5” in this case) from the pump to the filter bank could also increase the head and slow the flow down. Your vendor likely would have already discovered this instead of trying to sell you a new filter.

How is the flow rate being measured and how often?

- May 27, 2021

- 1,396

- Pool Size

- 17000

- Surface

- Fiberglass

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

Pictures of the plumbing setup would help. Do you have a bypass/metering loop for the heater or is all the water from the filters passing through the heater before returning to the pool?

No bypass for the heater.Pictures of the plumbing setup would help. Do you have a bypass/metering loop for the heater or is all the water from the filters passing through the heater before returning to the pool?

I'll take some pics and post along with proposed solutions from vendor.Either pictures or a drawing of your flow paths would help.

The flow meter is installed before the filters.At what point in the flow is the 170gpm required and/or measured? Before the filters? After the filters? At the return pipe to the pool?

Will post some pics along with proposed solutions.If you’re getting quotes for solutions from an honest company, I’m guessing they’ve eliminated the simple answers like valve positioning. Pictures wouldn’t hurt. Your vendor probably would appreciate it if you redacted any identifying info before you posted them.

This is what we received from a vendor to address the low flow rate:

The observed conditions of the outdoor pool filtration system are as follows:

Complete System Upgrade

The observed conditions of the outdoor pool filtration system are as follows:

- The age of the filter housings are unknown but at least 8 years old.

- The condition of the filter media are unknown. (Sand was checked last year and was reported in "good condition".)

- The multiport valves are completely compromised as they will drain the pool without ball valve in discharge line shut.

- The plumbing configuration is not hydraulicly efficient as the system is bushed down from 3” to 2” pipe before the system splits off the two filters.

- The largest problem is the failing multiport, although it is unknown how many GPM will be gained in that repair. Since the plumbing will need to be cut apart to change the multiport valve it is an opportune time to correct any hydraulic flow issues.

- Since the filters themselves are quite old and the fiberglass is known to warp and leak, the best solution is to completely replace the filters at this time and eliminate possibilities for future needed repairs.

Complete System Upgrade

- Remove 2 existing filters.

- Supply and install 2-TR100C filters including new multiport valves and media.

- Reconfigure inlet and outlet piping for filter system.

- Remove existing filter media and replace.

- Remove faulty multiport valves and multiport configuration.

- Remove and replace 2 existing multiport valves.

The vendor mentions the 3" pipe bushed down to 2" as being "hydraulic inefficient." This seems to be the same as what you are saying is a likely cause of the restricted flow. Flow rate is measured daily. The flow meter is a FlowVis flow meter installed in pipe between pump and filter.The TR-140 filter comes in residential and commercial models. The commercial models come in a 2” glued fitting and a 3” flanged fitting model. 3” PVC has a cross section that is 2.25 times the size of 2”, so if you have 3” running to 2 x 2” filters you have a restriction by default before you ever get “inside” the filter. Bypassing the filter (the recirculate position) at the multiport valve won’t eliminate that because the valve itself becomes the restriction.

I believe the pump specs a 2.5” inlet on it, which means running 2” PVC (or even 2.5” in this case) from the pump to the filter bank could also increase the head and slow the flow down. Your vendor likely would have already discovered this instead of trying to sell you a new filter.

How is the flow rate being measured and how often?