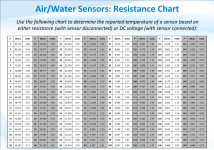

My three year old SWG is showing an error, “ Cold”, on the panel display. The SWG Cell has four wires coming out Temperature sensor side. I check the ohms for the blue and red wire and have 8700k ohms which sounds right for the temp. But what are the Orange and yellow wires going to and are they used.

I’ve read on other tech sites some RTD’s have a two wire thermistor and a two wire cold junction ref point for impedance correction. Does Aqua-rite use this? I’ve only seen ref. to a two, not a four wire temperature sensor. Any insight on this would be helpful, also I’m not sure which plug pins the Orange and yellow wires go to.

I’ve read on other tech sites some RTD’s have a two wire thermistor and a two wire cold junction ref point for impedance correction. Does Aqua-rite use this? I’ve only seen ref. to a two, not a four wire temperature sensor. Any insight on this would be helpful, also I’m not sure which plug pins the Orange and yellow wires go to.