Long story short, I’m finishing the plumbing job my contractor couldn’t get right and electricians will be here Monday to wire so I want to make sure to get this setup right. I had all new equipment put in and a paramount in ground cleaning system installed. The contractor told me I needed two pumps. One to run the cleaning system and one to run everything else. This doesn’t make ton of sense since they both need to share the same filter, skimmer etc. what I have are as follows:

pool with step jets

two surface returns

water feature

1 skimmer

6 Down sweep jets

4 pop up heads and the main drain

equipment:

jandy proflo vs

jandy proflo single stage

jandy cartridge filter

hayward salt chlorinated system

the current system was originally plumbed with the paramount cleaning system on the single stage and not running through the filter or the sale cell. That’s obviously not right since nothing in the “cleaning” system would get filtered or clorinated.

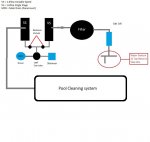

Fast forward to my contractor replumbing because cause I told him it was wrong, and now he got rid of the smooth sweep elbow out of the vs pump, ran them in parallel and then hard tee’d into the output of the filter but before the salt cell.

help. How the heck should this be plumbed? Here are a couple pics for reference. The valves after the salt cell go to the stairs, top returns and water feature.

pool with step jets

two surface returns

water feature

1 skimmer

6 Down sweep jets

4 pop up heads and the main drain

equipment:

jandy proflo vs

jandy proflo single stage

jandy cartridge filter

hayward salt chlorinated system

the current system was originally plumbed with the paramount cleaning system on the single stage and not running through the filter or the sale cell. That’s obviously not right since nothing in the “cleaning” system would get filtered or clorinated.

Fast forward to my contractor replumbing because cause I told him it was wrong, and now he got rid of the smooth sweep elbow out of the vs pump, ran them in parallel and then hard tee’d into the output of the filter but before the salt cell.

help. How the heck should this be plumbed? Here are a couple pics for reference. The valves after the salt cell go to the stairs, top returns and water feature.