Maybe they used it to add antifreezeI am not sure why they just did that one considering they lowered our water when they really shouldn't have

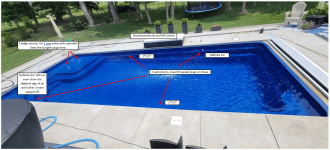

In order, from nearest to furtherst of the run. If you cap them out of order, you will trap water at the end which can't get out.Keeping in mind that I'm not lowering the water below returns, what's the best method to cap these?

It's surprisingly easy to cap under pressure. You'll do fine.My reasoning is that the last will probably be harder to cap off

I always prefer threaded fittings to expandable plugs because the ice may pop the expandables.

I don't like the 90 degree elbow either because the ice will have a good grip on it and if the ice rink shifts, it may break the return pipe in the wall.

Probably. But you're amongst your people here, so no finger pointing from me.Am I overthinking, as usual?