- Jul 15, 2023

- 41

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

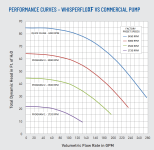

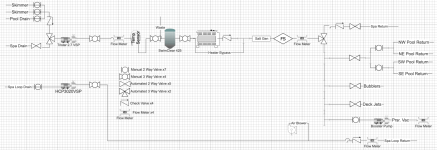

During the planning process we had philosophically agreed on the plumbing design. We would have two pumps - a very large one for spa circulation only - no filter - no heater. Just suck water in and spit it back out at high flow into the spa. A second pump would do "everything else." This would be for filtration of spa and pool, heat and heated water circulation of spa and pool, two bubblers. The smaller pump would also feed a corner 24" spa spillover as a return. This is planned to be a 7x7 spa, 16' x34' pool (water). We don't plan on running the waterfall a lot.

Now that we're in construction the PB wants to change things a bit. He wants the large pump to be for "everything." The smaller pump will be for the bubblers and the spa spillover, effectively making it a water feature pump. All returns, including spa jets will run through the filter and heater. Max flow rate through filter is 150GPM. Through filter is 125GPM.

Spa has 10 jets total over 6 positions. There are two his/her locations with 3 jets each. We plan on using two of these: Thread-in Jet Manifolds - Waterway Plastics.

There seems to be lots of caution here about running the spa through filtration and heater for flow. We also have some high flow jets planned - thus the reason to upgrade to the larger pump and why we designed it the first way. The PB is pushing back saying if something gets sucked up it will get through the system and damage things- that's why they run all returns through filtration.

Any thoughts? I've attached what was the scheduled design which closely matches what Hayward recommends in its paperwork. Also attached.

Now that we're in construction the PB wants to change things a bit. He wants the large pump to be for "everything." The smaller pump will be for the bubblers and the spa spillover, effectively making it a water feature pump. All returns, including spa jets will run through the filter and heater. Max flow rate through filter is 150GPM. Through filter is 125GPM.

Spa has 10 jets total over 6 positions. There are two his/her locations with 3 jets each. We plan on using two of these: Thread-in Jet Manifolds - Waterway Plastics.

There seems to be lots of caution here about running the spa through filtration and heater for flow. We also have some high flow jets planned - thus the reason to upgrade to the larger pump and why we designed it the first way. The PB is pushing back saying if something gets sucked up it will get through the system and damage things- that's why they run all returns through filtration.

Any thoughts? I've attached what was the scheduled design which closely matches what Hayward recommends in its paperwork. Also attached.