- May 17, 2021

- 101

- Pool Size

- 19500

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-45 Plus

Hello,

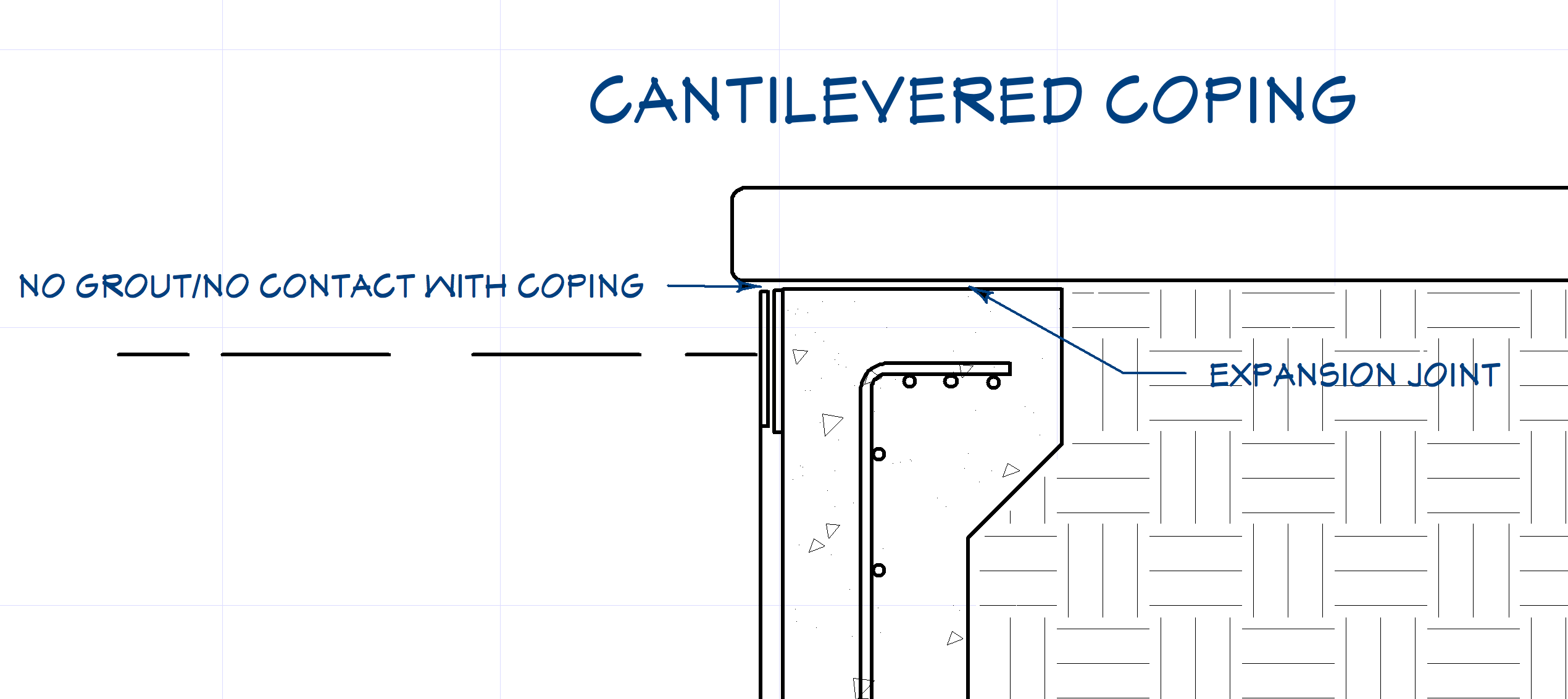

Looking to get some input in current state, mostly to calm my nerves, prior to cantilevered deck installation on my gunite pool. It will be poured as one pour, and 'attach' to an existing patio separated by a speed drain. I've reviewed the materials on TFP, and the Pool Engineering Inc site here: https://www.pooleng.com/wp-content/uploads/280.png

Concerned about lack of backfill, my pool shell has sat for ~60-days. It has been trenchs/plumbed for ~30-days. It's just been sitting, with no backfill for that time. I am thinking that proper back-fill needs time to settle before framing? Also, interested to see how they plan to decouple waterline tile as it's installed now.

I've attached sketch and real pics, let me know your thoughts. Thank you!

My proposed design sketch:

Current State of my backyard:

Looking to get some input in current state, mostly to calm my nerves, prior to cantilevered deck installation on my gunite pool. It will be poured as one pour, and 'attach' to an existing patio separated by a speed drain. I've reviewed the materials on TFP, and the Pool Engineering Inc site here: https://www.pooleng.com/wp-content/uploads/280.png

Concerned about lack of backfill, my pool shell has sat for ~60-days. It has been trenchs/plumbed for ~30-days. It's just been sitting, with no backfill for that time. I am thinking that proper back-fill needs time to settle before framing? Also, interested to see how they plan to decouple waterline tile as it's installed now.

I've attached sketch and real pics, let me know your thoughts. Thank you!

My proposed design sketch:

Current State of my backyard: