- May 14, 2013

- 54

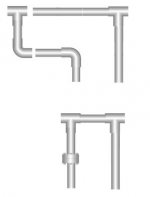

Replumbing to the left of the new Tee next to brass gate valve (hopefully to become a PVC ball valve). As you can see, no open areas of pipe to the right of brass valve. All fittings! I don’t want to rip out and redo that whole top line between the brass valve and the compression union far right! Is there a solution to get that cut riser into bottom of Tee?