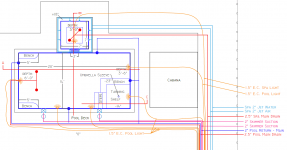

My pool builder is starting soon. I got a picture of the most recent equipment pad they are doing to see if I request any changes before they start mine. I don't really know all the best practices, hoping someone can review and offer suggestions. This particular build in picture has two pumps, where I will only be having one, but both are pool/spa combo, just mine is smaller. (7' x7' spa), 14x28' pool. Also they are using D.E. filter, where i'm going cartridge. same SWCG and heater though. Not doing booster pump, from recommendations on this forum ,going with a robot cleaner.

some of my thoughts.

1. bottom left, normal valves, why not jandy valves?

2. Jandy recommends long sweep elbows, and I don't see any.

3. Why check valves on jump intake?

4. intake straight pipe not long enough( should be 10" min i think)

5. I don't see manual bypass for pool heater, which I think is recommended

6. I'm assuming the clear thing T'ing off pool heater intake is for water bonding, but not sure

7. not shown in picture on bottom right is check valve right after heater outlet, which i know is recommended. Just not sure wisdom putting it right next to outlet, worried about heat damage? seems like they should have put right before SWCG inlet?

8. I thought doing CPVC or schedule 80 on heater outlet for some feet is recommnded, can't remember

9. seems like they could have reversed the pool heater, to potentially simplify plumbing a little

any other thoughts.

some of my thoughts.

1. bottom left, normal valves, why not jandy valves?

2. Jandy recommends long sweep elbows, and I don't see any.

3. Why check valves on jump intake?

4. intake straight pipe not long enough( should be 10" min i think)

5. I don't see manual bypass for pool heater, which I think is recommended

6. I'm assuming the clear thing T'ing off pool heater intake is for water bonding, but not sure

7. not shown in picture on bottom right is check valve right after heater outlet, which i know is recommended. Just not sure wisdom putting it right next to outlet, worried about heat damage? seems like they should have put right before SWCG inlet?

8. I thought doing CPVC or schedule 80 on heater outlet for some feet is recommnded, can't remember

9. seems like they could have reversed the pool heater, to potentially simplify plumbing a little

any other thoughts.