Hi everyone, we just opened our first pool yesterday after finally getting our build completed. We have a free-form 23000(ish)k plaster pool with a VS pump. I am still trying to understand when to run the pump at higher RPM's vs running it lower for longer. When I put in chemicals (right now it is chlorine for the first 30 days), do I need to turn the pump up to a higher RPM? How about when I am brushing the walls because of the fresh plaster? If so, how long do I run it for? Right now I have it set to run 23 hours on 1750 RPM. I believe someone mentioned for the first 2 weeks to run it all the time. Is that right? Sorry for all the newb questions, I just want to make sure I am doing this all correctly. Thanks!

When to run VS pump at higher RPM

- Thread starter Yarzy

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Jun 7, 2017

- 9,062

- Pool Size

- 29000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

I only run mine higher when the heater is on and 2 hours in the morning for better skimming. Other than that, it remains around 2k RPMs. I did run it for the first week of my pool on the highest setting 24x7 but I am not sure it was necessary the builder said to do it.

Thanks so much. So I wonder if I am not running it at a high enough RPM then? I am running at half speed for 23 hours. I just hope the plaster dust and all that is actually getting picked up.

- Jun 7, 2017

- 9,062

- Pool Size

- 29000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

Thanks so much. So I wonder if I am not running it at a high enough RPM then? I am running at half speed for 23 hours. I just hope the plaster dust and all that is actually getting picked up.

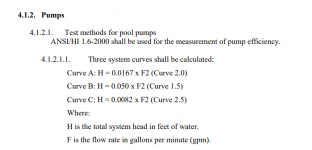

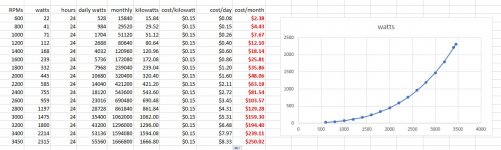

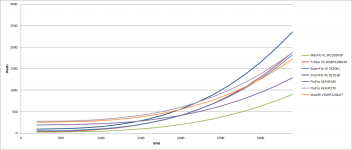

For water circulation and saltwater generators that is fine. A higher speed isn't going to do much more for plaster dust. Check out the below chart for how much it costs to run a VSP.

That is SUPER helpful, thanks! So if I am just maintaining the water in order to filter the plaster dust, new pool stuff, what RPM should I run it at. Any idea for how long?

I judge mine on filter pressure and if the spa water fall looks smooth. I keep my pressure around 4 and run it 23/7 most of the time.

- Jun 7, 2017

- 9,062

- Pool Size

- 29000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Jandy Aquapure 1400

That is SUPER helpful, thanks! So if I am just maintaining the water in order to filter the plaster dust, new pool stuff, what RPM should I run it at. Any idea for how long?

Do you have a SWG? Please fill out your sigline here -> https://www.troublefreepool.com/account/signature

- May 3, 2007

- 16,904

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

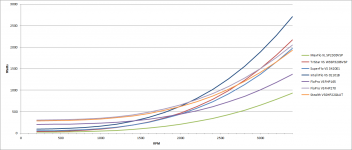

Note that the Jandy FloPro 1.65 VS is going to have a different power curve than the Jandy 2.7 VS (Stealth or FloPro?). Also, the plumbing system changes the curve as well.For water circulation and saltwater generators that is fine. A higher speed isn't going to do much more for plaster dust. Check out the below chart for how much it costs to run a VSP.

View attachment 345668

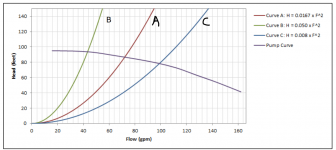

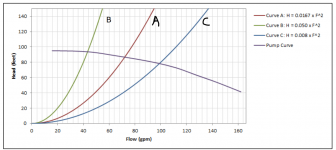

Plumbing Curve C:

Plumbing Curve A:

Last edited:

Thanks again and that is a very good point, they are totally different pumps. One question, what do you mean by "plumbing curve C"?

- May 3, 2007

- 16,904

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Plumbing Curve C represents typical 2" plumbing and has a head curve of:

Head (ft) = 0.0082 * GPM^2

Plumbing Curve A represents typical 1.5" plumbing and has a head curve of:

Head (ft) = 0.0167 * GPM^2

Head (ft) = 0.0082 * GPM^2

Plumbing Curve A represents typical 1.5" plumbing and has a head curve of:

Head (ft) = 0.0167 * GPM^2

red-beard

Gold Supporter

- May 27, 2019

- 1,621

- Pool Size

- 25000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite Pro (T-15)

With my Salt Water Generator, I need to run 1050 RPM to make it work. For the skimmers to really work, I find that 2800 RPM works well. So I run 20 hours a day at 1050 RPM and 2 hours, twice a day, at 2800 RPM. 1050 = 63 Watts and 2800 = 750 Watts. I do this 8 months per year. In the winter, the pump runs 24/7 at 1050. @7.9 cent/kWh, this is about $100/yr.

Curve A corresponds to a system with high head losses. This is typical of a new pool with 2” PVC plumbing.

Curve B corresponds to an older system with very high head losses. This is typical of a pool with 1 ½” plumbing.

Curve C corresponds to a system with medium head losses. This is typical of a new pool with 2 ½” PVC plumbing.

Curve B corresponds to an older system with very high head losses. This is typical of a pool with 1 ½” plumbing.

Curve C corresponds to a system with medium head losses. This is typical of a new pool with 2 ½” PVC plumbing.

- May 3, 2007

- 16,904

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Clearly James and I have different views on what the plumbing curves represent. There is a lot of variance depending on what one assumes. For example, if one assumes a pool/spa setup with single 35' runs, a cartridge filter, NG heater with internal bypass, pool/spa valves, 12x90s, 4x3/4" eyeballs, you would get the following plumbing curves for each pipe size.Curve A corresponds to a system with high head losses. This is typical of a new pool with 2” PVC plumbing.

Curve B corresponds to an older system with very high head losses. This is typical of a pool with 1 ½” plumbing.

Curve C corresponds to a system with medium head losses. This is typical of a new pool with 2 ½” PVC plumbing.

1.5" plumbing - Head (ft) = 0.01144 * GPM^2

2.0" plumbing - Head (ft) = 0.00691 * GPM^2

2.5" plumbing - Head (ft) = 0.00580 * GPM^2

If you assume a DE filter with a backwash valve, it gets closer to my definitions.

1.5" plumbing - Head (ft) = 0.01195 * GPM^2 - Between Curve A & C

2.0" plumbing - Head (ft) = 0.00814 * GPM^2 - Close to Curve C

2.5" plumbing - Head (ft) = 0.00719 * GPM^2 - Below Curve C

However, the reason I use Curve A for 1.5" plumbing is because older pools tend to have less eyeballs and small sand filters which greatly increase head loss. With 2x3/4" eyeballs and a 2 sq-ft sand filter , the curve constant becomes 0.01746 which is closer to curve A. In order to get to definitions James presented, it would require a significant increase in head loss somewhere.

BTW, Curve B is nearly impossible except for plumbing systems that have something seriously wrong with them.

skimmerswimmer

Well-known member

I run my pump at 7:30 AM for a couple of hours at 2300 rpm for initial skimming action, then it goes down to 1500 rpm for the rest of the day. It shuts off at 11:30 PM.

- May 3, 2007

- 16,904

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Yes, I have seen those definitions before and they are wrong. Do the calculations yourself (or via my spreadsheet) and you will see that they are wrong.

- May 3, 2007

- 16,904

- Pool Size

- 20000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Hayward Aqua Rite (T-15)

Again, they are wrong. Do the calculations yourself. Also, you can confirm with the dozens of head loss measurements done on this web site. They all fit closer to my definition.

So other data points, for curve-C to be 2.5", it would need to be the equivalent of 1500' of pipe. For Curve-A to be for 2" pipe would require the equivalent of about 1200' of 2" pipe.

So other data points, for curve-C to be 2.5", it would need to be the equivalent of 1500' of pipe. For Curve-A to be for 2" pipe would require the equivalent of about 1200' of 2" pipe.

Last edited:

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.