- Oct 25, 2015

- 5,233

- Pool Size

- 25000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- CircuPool RJ-60 Plus

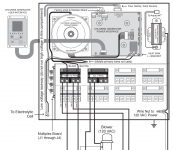

Wow, that is indeed a large and unusual system for a residential pool. For the swg you have two choices that allow you to keep most of your RS system. First, replace the defective parts in the 1st box. Sounds like it's a transformer and board. Or you can scrap the Jandy swg and convert to a 3rd party like Circupool and use the RS to control the swg on-off and run-time plus everything else in your system. I'd go with the latter for reasons explained above unless the repair to Jandy swg is much cheaper than it appears.

Can you please add your signature? It will help all the experts understand what you really have and what your options are without guessing. It's very easy, here's how.

I hope this helps.

Chris

Can you please add your signature? It will help all the experts understand what you really have and what your options are without guessing. It's very easy, here's how.

I hope this helps.

Chris