Ok. I got in touch with my waterfall/slide builder and since he is the actual person doing the work he said normally the plumber would run the right PVC size pipe. Since I am doing owner builder i want to make sure i get it right. Only feedback he had was waterfall, depending on the look i want, will need more water. the slide doesn't need much water. I added 1 more drain to give me piece of mind i will have plenty of suction for the waterfall no matter what the GPM need is. I can vary the RPM's. As the waterfall guy said its really up to me depending on looks.

I have used this waterfall guy once before, doesnt speak great english, but he is really good his end product is amazing so i am going to use him even though he cant give me a firm answer on GPM

also I thought it would be good to keep the same line size going back to the equipment pad (3"). I would rather not vary the line size so there are no excuses for the plumber "i thought this one was 2" not 3" type arguments". since i am doing owner builder i am trying to keep things consistent and really easy for me to verify that PVC pipe is same size and its the right size.

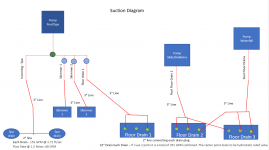

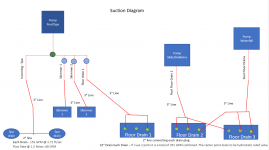

Here is my plan. Let me know what you think.

Note: This is just for the suctions. I will do the returns next. Remember equipment pad is 150' away.

Ok. I will effectively have 7 drains:

1) Skimmer 1

2) Skimmer 2

3) Floor Drain 1

4) Floor Drain 2

5) Floor Drain 3

6) Spa Drain 1

7) Spa Drain 2

From what i have read, the 32" waterway floor drains have 3 ports on them. The flow rate they give you is 352 GPM when using 2 ports combined. It sounds like the third port is a hydrostatic port (but has the same opening as the other ports).

So my thinking is, on floor drain 1 i would leave the middle port open to be used as my hydrostatic relief valve increase the water table comes up. the other 2 floor drains i will use all 3 as i only need 1 hydrostatic valve. I know the third port doesnt add GPM as they have no rating for that, but i do not want 3 hydrastic valves just from a failure standpoint. so i will tie all 3 ports into a drain even though i dont need that much suction.

Pipe Sizes. Please give me feedback.

1) I will tie Spa Drain 1 and Spa drain 2 together under the gunite using 2" PVC line. From there i will have a T that goes back to the equipment pad. That line will be 3"

2) Skimmer 1 will go directly back to the equipment pad using 3"

3) Skimmer 2 will go directly back to the equipment pad using 3"

4) Floor drain 1 - port A and Port C will be tied together under the gunite using 2" PVC. There will be a T and from there goes to the equipment pad with 3". The middle port, port B, will be left as a hydrostatic relief valve

5) Drain 2 & Drain 3 first run - Drain 2 - Port A & B, and Drain 3 Port A will be tied together using 2" PVC then goes back to the equipment pad with 3"

6) Drain 2 and Drain 3 second run - Drain 2 Port C, and Drain 3 Port B and C will be tied together using 2" PVC then goes back to the equipment pad with 3".

I randomly tied drains 2 and 3 together this way so i dont have any 1 pump on any 1 drain. The 32" waterway is listed as unblock able but i think i would feel better knowing for sure no way anyone can drown from sucking on the drain.

Thoughts on this plan?