- Mar 19, 2024

- 22

- Pool Size

- 14000

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

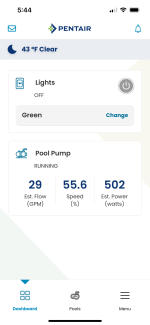

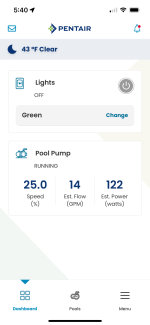

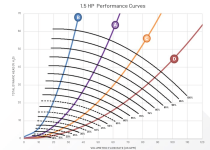

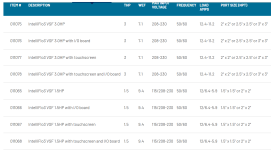

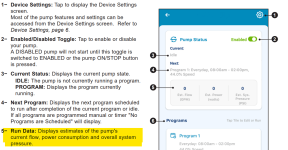

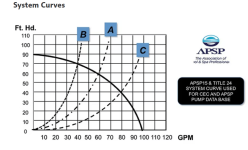

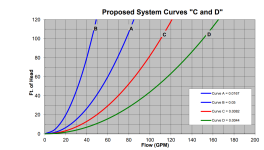

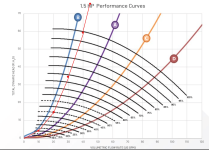

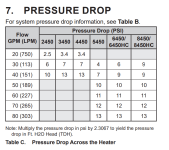

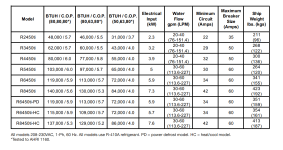

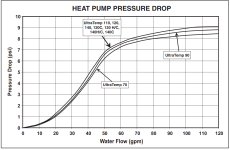

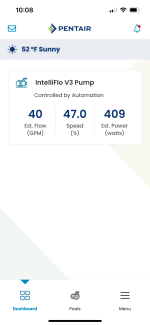

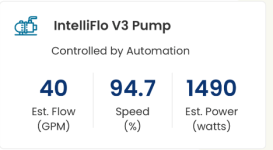

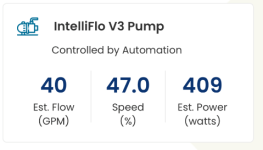

Hello, new to pools. Engineering degree. Pool installed last summer already Upgraded to an intillifloV3 pump everything is good. circulating 30gpm at 25% speed 150watts. I installed a Raypak (Rheem) 140k BTU heat pump pool heater, with a bypass valve (jandy neverlube) and a Hayward check valve on the outflow side of the heater. The problem when I turn on the heater at the recommended 45gpm my pump jumps to 95% speed and 1500watts. 10x the power consumption. Pressure gauge on filter jumps from 15 to 30PSI. Heater works, tested for 5 hours and it was going up about 1degF/hour @60F ambient. My question is this kind of flow restriction and pump load common or expected. Is this a common Raypak problem? It’s an impressive heat exchanger, thing is a monster seems very well build….now I am just wondering if they are no good at the fluid side? The heat pump loop is 10 feet of pipe total, 6 elbows, 2 x 45 degrees, and a Hayward check valve. Any thoughts?