- Jul 21, 2013

- 66,049

- Pool Size

- 35000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Yes, I understand that. To clarify, I have a multimeter that I can use to test resistance and capacitance, and an ammeter that I can use to test amperage on the black or red wire going to the motor. Thank you!You check the capacitor using the ohmeter resistance, not ammeter.

Separately you should check the amp draw of the blower and see it is within the specs of the blower motor. If the amp draw is high it would be the reason the ICM relay is burning out.

I have not needed to get that deep into my heater to see exactly how the blower motor and capacitor is accessed.

If you disconnect the F2 wire and measure the voltage from the F2 wire to ground, you are measuring the voltage from the black leg of the 240 volt supply.I get a reading of approx 120V on the F2 wire, which I'm told is not expected, and cannot be explained by Pentair tech support.

Yes I understand, to clarify, I do have a multimeter for checking resistance and capacitance, and an ammeter for checking the motor amperage on the black or red wire. Thanks for all your help.You check the capacitor using the ohmeter resistance, not ammeter.

Separately you should check the amp draw of the blower and see it is within the specs of the blower motor. If the amp draw is high it would be the reason the ICM relay is burning out.

I have not needed to get that deep into my heater to see exactly how the blower motor and capacitor is accessed.

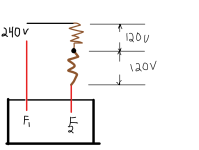

If you disconnect the F2 wire and measure the voltage from the F2 wire to ground, you are measuring the voltage from the black leg of the 240 volt supply.

The red leg goes to F1 and the relay from F1 to F2 closes when the blower should come on.

If you measure the voltage from the F1 terminal to the F2 wire while the F2 wire is disconnected from the F2 terminal, the voltage should be 240 volts.

If you measure the voltage from the F2 to ground before the blower is supposed to come on, with the F2 wire disconnected, the F2 terminal to ground voltage should be 0 volts.

If you measure the voltage from the F2 terminal to ground when the blower is supposed to come on and the F2 wire is disconnected, the F2 terminal to ground voltage should be 120 volts.

When you put 2 identical load in series, the voltage divides by 2.

So, the supply voltage is 240, but the voltage across each winding is 120 volts.

If you want to use a 120 volt supply, the loads get put in parallel.

This is how many dual voltage appliances can take 2 different voltages like a single speed pump motor or many of the SWG transformers.

One leg of the blower stays powered and only one leg gets switched.

View attachment 526116

Re: "If you measure the voltage from the F2 terminal to ground when the blower is supposed to come on and the F2 wire is disconnected, the F2 terminal to ground voltage should be 120 volts."If you disconnect the F2 wire and measure the voltage from the F2 wire to ground, you are measuring the voltage from the black leg of the 240 volt supply.

The red leg goes to F1 and the relay from F1 to F2 closes when the blower should come on.

If you measure the voltage from the F1 terminal to the F2 wire while the F2 wire is disconnected from the F2 terminal, the voltage should be 240 volts.

If you measure the voltage from the F2 to ground before the blower is supposed to come on, with the F2 wire disconnected, the F2 terminal to ground voltage should be 0 volts.

If you measure the voltage from the F2 terminal to ground when the blower is supposed to come on and the F2 wire is disconnected, the F2 terminal to ground voltage should be 120 volts.

When you put 2 identical load in series, the voltage divides by 2.

So, the supply voltage is 240, but the voltage across each winding is 120 volts.

If you want to use a 120 volt supply, the loads get put in parallel.

This is how many dual voltage appliances can take 2 different voltages like a single speed pump motor or many of the SWG transformers.

One leg of the blower stays powered and only one leg gets switched.

View attachment 526116

Correct, I explained why the wire would show 120 to ground.I wanted to add that when the F2 wire is disconnected from the F2 terminal, it also reads 120V when the heater is off.

Regarding reading the voltage through the windings. When I previously unplugged the blower motor connector, and measured for continuity between Pin 1 (red wire) and Pin 3 (black wire) on the blower side of the connector I got no continuity. I never checked the actual resistance, but I would expect there would be a significant amount of conductance if the voltage can be read through the windings (unless there is a switch/relay inside that closes when the red wire is hot) . I believe I did see some voltage drop on the F2 wire reading. If I remember correctly the red wire was 119V and the black wire was 116V, when the heater was off. Thanks!Correct, I explained why the wire would show 120 to ground.

It is because the voltage from the other leg transfers through the windings to the F2 wire.

However, I was describing the voltage at the F2 terminal, which is on the Fenwal.

Thanks that make sense to me now. When I get a chance to do the tests I'll let you know the results. Thanks again for all your help, I'm learning a lot.The windings are not connected when you have the connector disconnected.

The connection is made by the voltage selector plug.

That is the purpose of the plug.

The wires are different to connect the windings in series or parallel.

View attachment 526204

The blower has 3 sets of windings.

2 main run windings and an auxiliary start winding.

Red and blue go to one set of windings.

Black and yellow go to the other set.

For 120 volts, the windings are in parallel.

For 240 volts, the windings are in series.

The auxiliary start winding is in parallel with the black --> yellow winding.

Remove the capacitor and test for resistance from red to blue and black to yellow. The values should be the same.

Label the capacitor wires C1 and C2. Test from C1 to C2, C1 to black, C1 to yellow and C1 to white.

Test from C2 to black, C2 to yellow and C2 to white.

Test from each wire to the green ground wire to see if any wires are shorted to ground.

View attachment 526201

You hit the nail on the head. I'm quite sure mice were the problem. When the heater would not start after not using it over the winter, I opened it up to check it out. Every square inch of the enclosure was stuffed with mouse nesting. I had to fix and replace a number of wires. None of the wires were chewed all the way through, but the F1 wire had a a fair number of broken strands. There was a dead mouse inside the control box that I suspect was electrocuted by the F1 wire. I replaced any wire with broken strands, and patched any wire jacket insulation that had chew marks on it with heat shrink. I went through all the wire quite thoroughly, and cleaned all the grounds, but will check again if get stumped on the repair.If you measure the voltage from the F2 terminal to ground when the blower is supposed to come on and the F2 wire is disconnected, the F2 terminal to ground voltage should be 120 volts.

Disconnect the F2 wire and then measure the voltage from the F2 terminal to ground when the blower should come on.

Remove the red voltage selector plug and check it for damage.

Mice like to chew on the wires and the wires might be damaged.

Check all wiring for signs of damage.

This information should have been included in the first post.Every square inch of the enclosure was stuffed with mouse nesting. I had to fix and replace a number of wires.

Sorry, I did not include that info in the first post, because I wanted to eliminate the motor as the problem first before going any further. If the motor is shot, I may just buy a new heater. Pentair had told me I should replace the motor because of the 240V reading I was getting between the F1 & F2 wires. Based on what you have explained, I now know the 240 V reading is correct and Pentair gave me bad information. The Pentair tech said that in heaters configured for 240V, nothing except the transformer actually runs on 240V, and that the blower motor and ignitor in a 240V system are wired exactly the same as in a 120V system. I asked him if that was the case, what was the point of offering a 240V config. He said that the only reason they have it is to accommodate customers who only have 240V available at their install location. Thanks.This information should have been included in the first post.

I don't have an ICM right now to test that on. My original one burnt up, and I returned the used one I ordered. Hoping to do the motor tests this weekend. If I can confirm the motor is OK, I will order another ICM. Thanks!I suspect that the problem is most likely a bad wire somewhere.

Did you measure for 120 to ground from the F2 terminal while the F2 wire was disconnected?