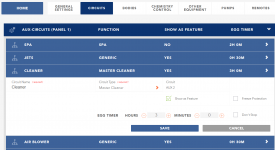

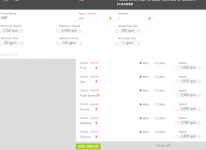

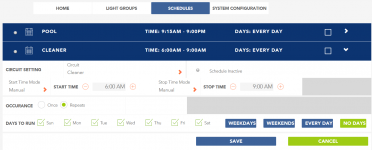

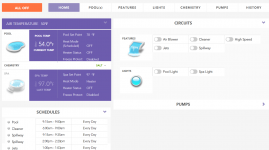

I had the main circuit board on my intellicenter replaced due to a short. Once replaced I lost all my programming and had to redo it all. Previously my pool installer had done it a few years ago. Got most of it figured out but still need help.

- How do I program my pressure side cleaner to run during its schedule (11am-2pm) where the pool pump increases to max speed and the booster pump turns on

- I have a deep-end bench seat with "jets". I want to enable a feature where to turn on the jets the following happens: pentair intellivalve switches returns from the normal pool returns to the bench returns, air blower turns on, heat pump turns on. Is there a 1-button feature to do this?

Is there any good tutorials on intellicenter programming steps?

Pictures of my setup below:

- How do I program my pressure side cleaner to run during its schedule (11am-2pm) where the pool pump increases to max speed and the booster pump turns on

- I have a deep-end bench seat with "jets". I want to enable a feature where to turn on the jets the following happens: pentair intellivalve switches returns from the normal pool returns to the bench returns, air blower turns on, heat pump turns on. Is there a 1-button feature to do this?

Is there any good tutorials on intellicenter programming steps?

Pictures of my setup below:

Attachments

Last edited: