- Dec 23, 2021

- 18

- Pool Size

- 22000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-40

We have an ongoing owner build in Fort Worth, TX and could use some advice. We finished the steel before the current ice storm and are about to start plumbing.

Here's one of the renderings showing an overall view of the project:

The equipment pad is going to be along the side of the house near the shallow end in the above rendering. It's about 25' from the pad to the nearest corner and then another 15' or so to the nearest spa corner. The patio with a solid cover is existing and is 10'x14', while the pergola is notional at this point. The rest of the yard was grass before excavation started and we're going to end up with grass only along the deep end and between our house and the neighbors to each side (we're in a suburban residential area).

Here are some pool and plumbing details:

What I'm really wondering about is the plumbing, because that's what's coming right up. I should add that, even though I've never done this type of work before, I'm hoping to do as much of it as I can myself. Partly to save money (maybe?) and partly out of interest and the hope that I'll know how all this pool stuff works when I'm done (for fixing it later).

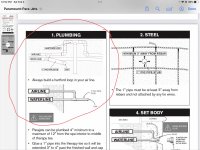

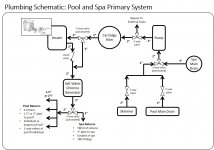

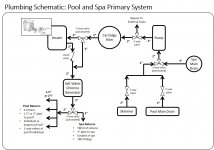

Here's a schematic I've started (it doesn't show the spa booster pump or water feature pump details yet, but we can still talk about them):

Feel free to provide advice on anything, but here's where I have specific questions:

Thanks for any help!

Here's one of the renderings showing an overall view of the project:

The equipment pad is going to be along the side of the house near the shallow end in the above rendering. It's about 25' from the pad to the nearest corner and then another 15' or so to the nearest spa corner. The patio with a solid cover is existing and is 10'x14', while the pergola is notional at this point. The rest of the yard was grass before excavation started and we're going to end up with grass only along the deep end and between our house and the neighbors to each side (we're in a suburban residential area).

Here are some pool and plumbing details:

- Rectangular in-ground pool with attached spa

- 13' to 16' wide by 40' long pool: 580 sq ft surface area, 110' perimeter

- 7x7 spa: 49 sq ft surface area, 28' perimeter

- About 22000 gal of water

- Plumbing details

- Pumps: 3 Pentair Intelliflo3 VSF (011075)

- Main pool/spa pump

- Spa booster pump

- Water feature pump for 2 LED bubblers and 1 sheer descent (3' wide)

- Filter: Pentair Clean and Clear Plus 420 (160301)

- Heater: Pentair Mastertemp 400k Natural Gas (460736)

- Chlorine: Pentair Intellichlor IC40 SWCG (came with intellicenter 521903)

- Pool stuff:

- 1 skimmer (yes, we should have 2, but we're not)

- 1 main drain

- 1 sidewall drain (for water feature pump)

- 1 suction cleaner line? (we plan to use a robot, but this would be a backup option)

- 4 Pool returns (we could add 1 more along the long continuous side)

- Autofill with overflow included

- Spa stuff:

- 1 spa main drain

- 1 spa sidewall drain (for spa booster pump)

- The exact # of fittings and type are TBD

- With the main pump in spa mode + the booster pump, we should be able to deliver over 200+ GPM in total

- 2 air blowers (1 for each pump): Air Supply Silencer 1.5 HP (6315241)

- Pumps: 3 Pentair Intelliflo3 VSF (011075)

What I'm really wondering about is the plumbing, because that's what's coming right up. I should add that, even though I've never done this type of work before, I'm hoping to do as much of it as I can myself. Partly to save money (maybe?) and partly out of interest and the hope that I'll know how all this pool stuff works when I'm done (for fixing it later).

Here's a schematic I've started (it doesn't show the spa booster pump or water feature pump details yet, but we can still talk about them):

Feel free to provide advice on anything, but here's where I have specific questions:

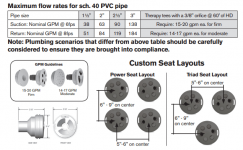

- Is 2" PVC from the skimmer and main drain adequate?

- I plan to run individual lines for each, with maybe 2/3 of flow from skimmer and 1/3 from the main drain

- I'm not an experienced pool owner, but I think I plan to run the pump 24/7, with a low RPM and then increase only as needed for specific things. It would only take 15 GPM to turn over the 22,000 gallon pool volume once per day.

- Is it OK to have 2" from the pool and 3" from the spa coming into the 3-way valve for the main pump?

- I plan to use 3" PVC from the spa drain, so would I reduce to 2" before the 3-way valve?

- What size pipe should I use going from the 3-way valve into the pump?

- What I'm really worried about is hampering the benefit of the 3" coming from the spa by using less than 3" for the 3-way and into the pump. Is that a valid concern?

- I have a similar concern related to the 3-way valve right before the returns, where I plan to use 3" PVC for the spa returns/jets.

- On the pool returns, I've read a lot about the benefits of individual lines (home runs), so I'm willing to do that, but I'm not 100% decided.

- If they're individual lines, what would that look like coming out of the 3-way valve after the SWG?

- Would I come out at 2" and then convert to 1.5" for each individual line?

- Or would I use 2" all the way to the return fitting and wait to reduce down to the fitting size there?

- If we loop the returns, what does that look like?

- Do I just tee off going into the pool and then create a loop of 2" (?) pipe around the pool and then tee off and reduce size at each return location?

- Other than isolating leaks in the future, has anyone had issues with looped returns (and what are they)?

- If they're individual lines, what would that look like coming out of the 3-way valve after the SWG?

- Heater bypass

- I'm planning to have an automated 3-way valve to bypass the heater.

- In Texas it's warm enough that I think there will be long periods of time where we don't use the heater, so it seems like a good idea to be able to completely bypass it.

- I have it automated, so if we want to heat the spa we can switch to that automatically.

- Thoughts on this?

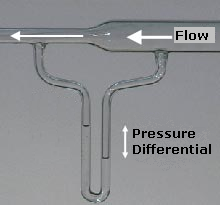

- Bypass between the pump and filter

- I'm also planning to have a (manual) 3-way valve to bypass between the pump and filter.

- My rationale for this bypass is less clear, but one reason would be to drain/lower the pool for whatever reason and have a way to attach that to a hose out to the street to avoid flooding the yard between us and our neighbor.

- Thoughts on this?

- For the water features, this is as far as I've gotten with my planning:

- 2 LED bubblers: run individual 2" lines to each, with a 2-way valve to adjust flow

- 1 sheer descent (3' wide): individual line (2", 2.5" or 3"?) with a 2-way valve to adjust flow

- Should we consider more sheers/coverage than the single 3'?

- Automated 3-way valve to adjust flow between the 2 features

- In general, I'm the least certain what I want to do in the spa, so advice here is much appreciated

- We're planning to do a rolled edge

- Seat configuration?

- There are no seats on the spillway side

- Would you plan for 2 seats along each of the other 3 sides, so 6 seats for a 7'x7' spa?

- I'm 6' and my wife is 5', so I already want to do a split bench height

- Jets

- I'm thinking about using this jet array product for at least 1 seat (mine): Jet Array - CMP

- Any other recommendations on jet fixtures or spa details?

- Dry-fitting PVC

- I've heard that you should dry-fit everything first, but I imagine it's tough to get the PVC to separate afterwards

- Is there any trick to getting the parts to separate?

Thanks for any help!