Copy. That was an option and just use two pumps and use the xf as primary and spa. And 3 sheer decents (total 60 inches )for second pump.

4 awg wire.

- Thread starter Alaterreur

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Because you are using #4 AWG copper THHN, you can use an 80 amp circuit breaker to supply the subpanel and this will allow you to load to 64 amps using the 80% rule.

Assuming a 200 foot total cable length, you can load to 62 amps and the voltage drop will be about 2.97%, which is less that the 3% maximum voltage drop.

Assuming a 200 foot total cable length, you can load to 62 amps and the voltage drop will be about 2.97%, which is less that the 3% maximum voltage drop.

Note that the ampacity of the wire has to be derated for ambient temperatures over 30C or 86F.

The ampacity of THHN copper at temperatures up to 86 degrees Fahrenheit is 95 amps.

However, if the wire will be hotter than 86 degrees Fahrenheit, you have to derate them by the correction factor.

For example, at temperatures between 114F to 122 F, the derating factor is 0.82.

95 x 0.82 = 77.9 amps.

In this case, the breaker would have to be smaller than 77.9 amps.

So, if you used a 70 amp breaker, you could plan to load to 56 amps.

If the temperature will be less than 113 F, the derating factor is 0.87, which is 82.65 amps and you could use an 80 amp circuit breaker and load to 64 amps using the 80% rule or 62 amps to keep the voltage drop below 3%.

The ampacity of THHN copper at temperatures up to 86 degrees Fahrenheit is 95 amps.

However, if the wire will be hotter than 86 degrees Fahrenheit, you have to derate them by the correction factor.

For example, at temperatures between 114F to 122 F, the derating factor is 0.82.

95 x 0.82 = 77.9 amps.

In this case, the breaker would have to be smaller than 77.9 amps.

So, if you used a 70 amp breaker, you could plan to load to 56 amps.

If the temperature will be less than 113 F, the derating factor is 0.87, which is 82.65 amps and you could use an 80 amp circuit breaker and load to 64 amps using the 80% rule or 62 amps to keep the voltage drop below 3%.

- May 23, 2015

- 25,697

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

Why 3 pumps? Seems like a waste of money to me. Using all separate pumps as opposed to valve automation is a little old school.

A single IntelliFlo can easily control both a pool and spa. There’s really no need for a separate spa pump. If you want more ooomph from the spa then add an air blower. As for the water feature, just get a smaller rated VSP rather than the IF3. Once you get the flow established out of the waterfall plumbing that you want, you will rarely, if ever, change it.

A single IntelliFlo can easily control both a pool and spa. There’s really no need for a separate spa pump. If you want more ooomph from the spa then add an air blower. As for the water feature, just get a smaller rated VSP rather than the IF3. Once you get the flow established out of the waterfall plumbing that you want, you will rarely, if ever, change it.

Mat we are planning on a 7x8 spa with 8-10 jets and want to make sure there is enough power (wife would like some foot jets if possible). On the 3 Sheer descents (two 18” and one 24), yes we may reduce the size. I just want to make sure the wires I install is sufficient should we do 3 pumps. I plan to begin the dig within the next two weeks.

James thanks for your help and I plan do do more reading. 4Awg hot and 8 Awg for neutral and ground will probably be the route I do but will confirm with the inspector.

James thanks for your help and I plan do do more reading. 4Awg hot and 8 Awg for neutral and ground will probably be the route I do but will confirm with the inspector.

- May 23, 2015

- 25,697

- Pool Size

- 16000

- Surface

- Plaster

- Chlorine

- Salt Water Generator

- SWG Type

- Pentair Intellichlor IC-60

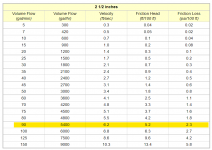

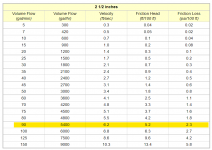

The intelliflo 3 is a 3HP pump at full rated speed. If the plumbing valves draw entirely from the spa and return to the jets, I can’t imagine needing more than that. I have a 5 jet spa, no feet bubblers, and it hurts if I run the jets any higher than 2400 RPM. If you post the plumbing details of what jets you intend to use as well as the pipe size and run length, @mas985 (Mark) may be able to give you some flow specs on what you need. Also, if you can give details on the brand of sheer descents used along with the fall height, he may be able to calculate the needed flow rate for the sheers. As for the sheers, if you can find one, you may be able to just use a simple water feature pump (runs at half the RPM of a single speed) instead. Open pipe water features like sheers don’t need the high head produced by a pool pump but, rather, they need high volumetric flow rates. Water feature pumps are designed to be high flow, low head pumps. As such, they consume less power than a traditional single speed or variable speed pool pump but can easily move twice as much water volume.

In my opinion, the IntelliFloXF VSF is a better pump.

If you can find the XF for a good price, I would consider going with the XF.

The XF will be quieter for the same flow, which can be important if the equipment will be near the house or pool.

The availability seems limited and the price will be higher.

If it is a lot higher, I would not think that it is worthwhile.

www.pentair.com

www.pentair.com

The variable speed is nice for sheers because they can often be too strong or not strong enough and sometimes you want more or less depending on the circumstances.

I think that you should be ok to use an 80 amp breaker on the supply line and load up to 60 amps.

Are you getting the IntelliCenter automation?

How far will the pumps be from the pool?

Be sure to size the lines correctly, especially for the suctions.

Almost all builders undersize the suctions on high flow applications.

If you can find the XF for a good price, I would consider going with the XF.

The XF will be quieter for the same flow, which can be important if the equipment will be near the house or pool.

The availability seems limited and the price will be higher.

If it is a lot higher, I would not think that it is worthwhile.

IntelliFloXF VSF Pump

Pentair IntelliFloXF VSF Pump - This innovative, variable speed & variable flow pool pump offers precision and savings for large and feature-rich pools.

The variable speed is nice for sheers because they can often be too strong or not strong enough and sometimes you want more or less depending on the circumstances.

I think that you should be ok to use an 80 amp breaker on the supply line and load up to 60 amps.

Are you getting the IntelliCenter automation?

How far will the pumps be from the pool?

Be sure to size the lines correctly, especially for the suctions.

Almost all builders undersize the suctions on high flow applications.

For suction, you want to keep the water velocity below 6 ft/sec. For returns, you want to keep the water velocity below 8 ft/sec.

Size.......6 ft/sec......8 ft/sec.

1.5"...........38...............51 gpm

2"..............63...............84 gpm

2.5............90.............119 gpm

3.0".........138.............184 gpm

18 gpm per foot is 90 gpm total.

For 90 gpm, you can use 2.5" pvc for the suction.

For 100 gpm or higher, you can use 3" for the suction.

The IntelliFloXF can do 100 gpm at about 1,900 rpm or lower as long as the plumbing is sized correctly.

Size.......6 ft/sec......8 ft/sec.

1.5"...........38...............51 gpm

2"..............63...............84 gpm

2.5............90.............119 gpm

3.0".........138.............184 gpm

For 5 feet, you will need up to 100 gpm, which is 20 gpm per foot.And 3 sheer decents (total 60 inches )for second pump.

18 gpm per foot is 90 gpm total.

For 90 gpm, you can use 2.5" pvc for the suction.

For 100 gpm or higher, you can use 3" for the suction.

The IntelliFloXF can do 100 gpm at about 1,900 rpm or lower as long as the plumbing is sized correctly.

Here are the plans attached. Looking at running 2 1/2 inch pipes suction And return to spa (Approximately 70 feet away from equipment ). Looking at placing 2 jets on each wall of the spa. May add 2 more for feet but not as important.

Attachments

How many total jets and what is the flow required per jet?Looking at placing 2 jets on each wall of the spa.

For example, 8 jets at 15 gpm per jet is 120 gpm total and that would require 3" suction.

For 120 gpm, the XF would need to run at about 2,750 rpm.

Variable speed pumps tend to get loud above 2,750 rpm, so I would try to keep the speed below that if noise is an issue.

Yes will have an intellicenter and jets have not been picked yet. At 15 gpm may need that secondary pump.How many total jets and what is the flow required per jet?

I was thinking of have 3-4 jets on the Main pump which would be used mostly when it’s only my wife and I. And the second pump to run the rest when we have company. Thoughts?

That's mostly a personal preference depending on what you like.I was thinking of have 3-4 jets on the Main pump which would be used mostly when it’s only my wife and I. And the second pump to run the rest when we have company. Thoughts?

Will the system be at the same elevation as the pool or higher or lower?

If higher or lower, by how much?

If higher or lower, by how much?

The equipment will be the same level as the pool and the spa is raised 18”.Will the system be at the same elevation as the pool or higher or lower?

If higher or lower, by how much?

What about changing the nozzle tee with 1/4 inch? Would that reduce the gpm?How many total jets and what is the flow required per jet?

For example, 8 jets at 15 gpm per jet is 120 gpm total and that would require 3" suction.

For 120 gpm, the XF would need to run at about 2,750 rpm.

Variable speed pumps tend to get loud above 2,750 rpm, so I would try to keep the speed below that if noise is an issue.

Each jet has different characteristics based on the flow and pressure.

Smaller orifices concentrate the stream into a sharper and smaller diameter.

Each person is going to have their own personal preferences as to the characteristics of the jet.

You will have to review the different jets and choose the ones you prefer based on the flow characteristics.

Then, you look at the minimum and maximum flow specified per jet and multiply by the number of jets.

Smaller orifices concentrate the stream into a sharper and smaller diameter.

Each person is going to have their own personal preferences as to the characteristics of the jet.

You will have to review the different jets and choose the ones you prefer based on the flow characteristics.

Then, you look at the minimum and maximum flow specified per jet and multiply by the number of jets.

One last question, if I did run two pumps because of so many jets, would I have to install two air lines or can they be attached onto one 2 inch Venturi air line To run all the jets.

Will all of the jets be on one pump?

Will you have a blower?

The air line has to be sized for the amount of air flow as well as the pipe length.

Will you have a blower?

The air line has to be sized for the amount of air flow as well as the pipe length.

Thread Status

Hello , This thread has been inactive for over 60 days. New postings here are unlikely to be seen or responded to by other members. For better visibility, consider Starting A New Thread.