@MCF50

Let me see if I can hit a couple of points without the benefits of fully consuming my first cup of coffee.

Yup, there is nothing "logical" about how IntelliCenter operates, manages interfaces, communicates etc., etc. It's almost like Pentair chose to employ a group of Monkey's they obtained cheaply from a defunct zoo, gave them some name tags that said "software engineer" , didn't feed them enough banana's and set them to work on Pentair's "flagship" (I use that term loosely) pool automation system called the Pentair IntelliCenter.

1. The one advantage to using the iOS app is that you have the option to connect locally to your OCP (Outdoor Control Panel). Since the web-client utilizes third-party servers that are down more times than up, that helps.

2. But, the web-client is much more user-friendly when it comes to configuring your Feature Circuits, Circuit Groups (macros), pump speeds, schedules, etc. I recommend that you use it for at least initial setup/configurations. It can be a real pain to use at times (slow, unresponsive, clunky, etc) but just hang in there with it.

3. Here is my recommendation but it will add one more step that may irritate you and I get it. But it's the only thing I can think of as a "work-around" so you can accomplish your end-state.

(a) For this scenario, create two Circuit Groups (macros).

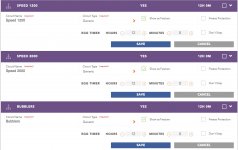

(b) The first one is your normal pool cleaning group. Let's just call it "Normal" for discussion purposes. It should contain the Feature Circuits - Pool and a Feature Circuit called say "Speed2000". This Feature Circuit (Speed2000) will be associated with a pump speed of 2000 rpm in your pumps page.

(c) The second Circuit Group let's call "Bubblers". It will have the following Feature Circuits embedded - Pool, a Feature Circuit called say "Speed1200". This Feature Circuit (Speed1200) will be associated with a pump speed of 1200 rpm in your pumps page. Lastly you should have a Feature Circuit embedded in this Circuit Group that is associated with the valve actuator that opens the bubbler valve.

4. In order to do what you want to do, you will need to insure that the pump speed that is associated with your pool body circuit in your pumps page is set lower than the above speeds. Say, 1000 RPM.

5. When you want to transition from the "Normal" Circuit Group (pump speed of 2000) to the "bubbler" Circuit Group (pump speed of 1200), merely turn off the "Normal" Circuit Group and turn on the "bubbler" Circuit Group. When you are done with the bubblers, do the opposite.

Here are some screen captures from my web-client that should give you an idea since capturing screen shots from the iOS app would not really help since I would have to capture many more embedded screens.

Feature Circuits

View attachment 314794

Circuit Groups (macros)

View attachment 314795

Pumps Page

View attachment 314796

Valves Page

View attachment 314797

There is possibly more ways to skin this cat but this is what I have been able to come up with. It's simplified but effective...

Good luck Sir...

r.

EDIT. One thing I forgot to mention. In my opinion, it's good operating practice to make the "Pool" body circuit the lowest pump speed possible and practicable. Helps all around to keep things from getting discombobulated.