I'm not sure if my pool is plumbed properly. I'm currently fighting a plumbing leak so if I'm going to replace 2 valves I want to do any other required or recommended plumbing at the same time, especially related to the main drain.

My pump pad is below the pool so as you can imagine any leak in valves, with winterizing plugs removed, means lots of lost water.

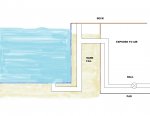

My main drain comes off the drain, rises up at the edge of the pool through sand fill, exits the outer support wall and goes down to the pump. About 9 feet of PVC pipe is exposed before the first valve, which is the leaking culprit (a cheap ball valve). At it's highest point it has an access plug through the pool deck which I believe could be used for either of 2 things. #1 adding antifreeze to this exposed line (which will also add some back to the drain as well), or #2 inserting a test-ball (inflatable plug) to stop the flow of water for plumbing repairs.

Currently there is no way to drain this unless the pool level is lowered in the winter, which is a problem for the cover.

I have a test plug I can use to stop water flow while doing repairs. The problem I have is that I don't know the best way for this to be routed. I can remove boards from the pool deck and excavate sand to a level a couple feet down if plumbing changes to the riser part are needed. I envision the ideal way to do this is to have some sort of valve similar to a fire hydrant in the pool deck, but the actual shutoff portion is down in the sand where it will be less prone to freezing. But that seems like I may be overthinking this as there would be no way to maintain such a valve. Is the best way really to just dump a bunch of antifreeze in that 9' section of pipe so it doesn't freeze? Seems like a way to ensure that if a leak occurs you keep losing the antifreeze.

My pump pad is below the pool so as you can imagine any leak in valves, with winterizing plugs removed, means lots of lost water.

My main drain comes off the drain, rises up at the edge of the pool through sand fill, exits the outer support wall and goes down to the pump. About 9 feet of PVC pipe is exposed before the first valve, which is the leaking culprit (a cheap ball valve). At it's highest point it has an access plug through the pool deck which I believe could be used for either of 2 things. #1 adding antifreeze to this exposed line (which will also add some back to the drain as well), or #2 inserting a test-ball (inflatable plug) to stop the flow of water for plumbing repairs.

Currently there is no way to drain this unless the pool level is lowered in the winter, which is a problem for the cover.

I have a test plug I can use to stop water flow while doing repairs. The problem I have is that I don't know the best way for this to be routed. I can remove boards from the pool deck and excavate sand to a level a couple feet down if plumbing changes to the riser part are needed. I envision the ideal way to do this is to have some sort of valve similar to a fire hydrant in the pool deck, but the actual shutoff portion is down in the sand where it will be less prone to freezing. But that seems like I may be overthinking this as there would be no way to maintain such a valve. Is the best way really to just dump a bunch of antifreeze in that 9' section of pipe so it doesn't freeze? Seems like a way to ensure that if a leak occurs you keep losing the antifreeze.